Ringspann Work Holding Technology

Innovative design processes have helped RINGSPANN lead the way in the work holding sector for over 70 years and the company has backed up success with investment in 13 subsidiaries worldwide,

Innovative design processes have helped RINGSPANN lead the way in the work holding sector for over 70 years and the company has backed up success with investment in 17 subsidiaries worldwide, including manufacturing plants in Germany, China, U.S.A., India and South Africa. This gives RINGSPANN the capability of reacting to the needs and demands of customers in the most demanding of industrial sectors such as,

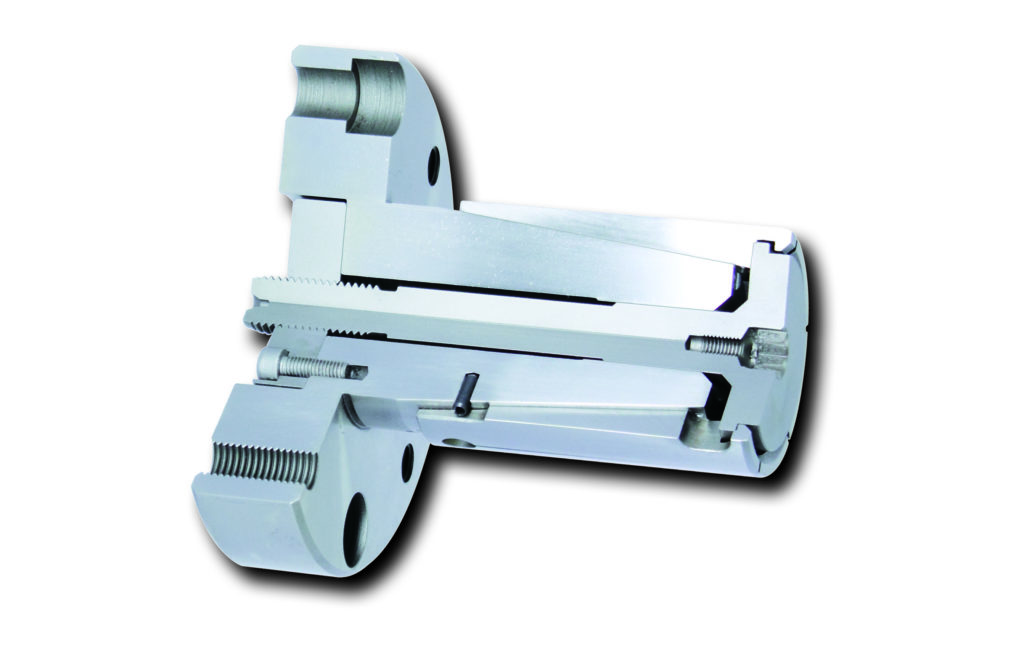

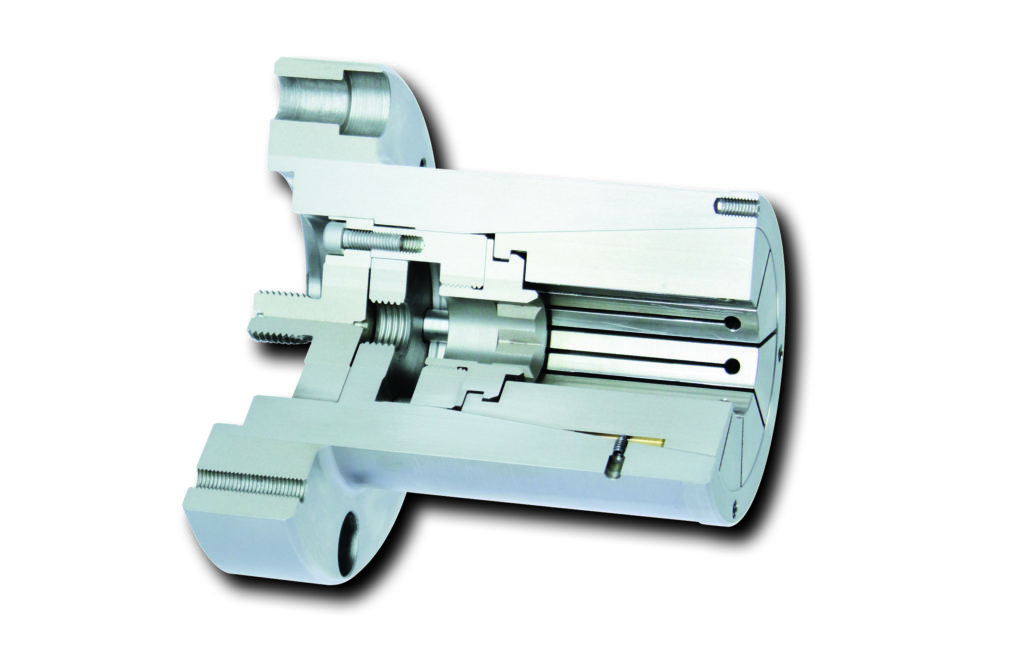

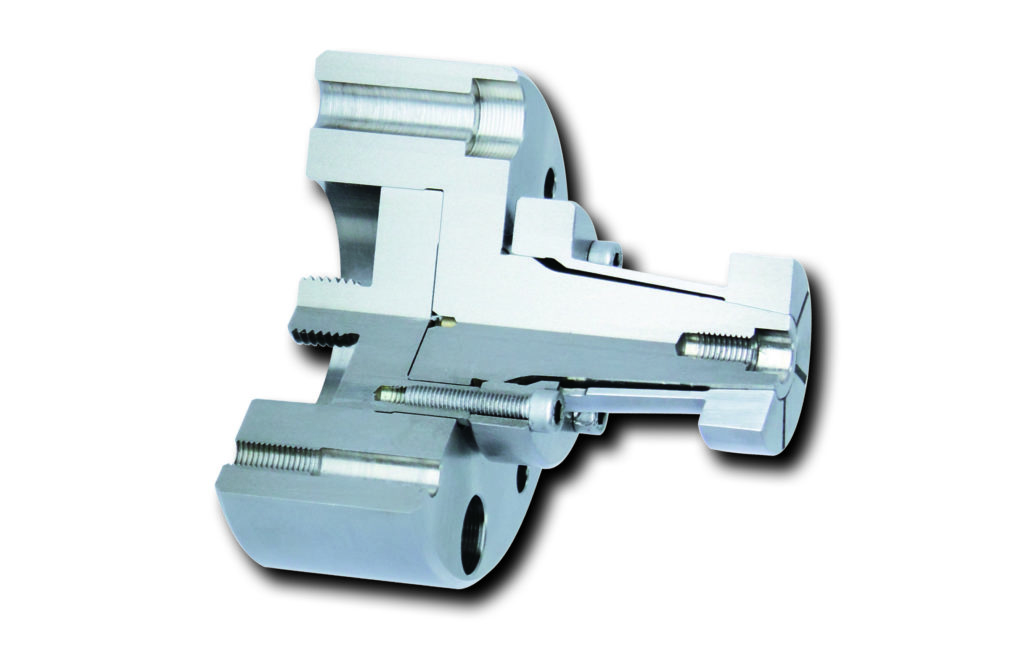

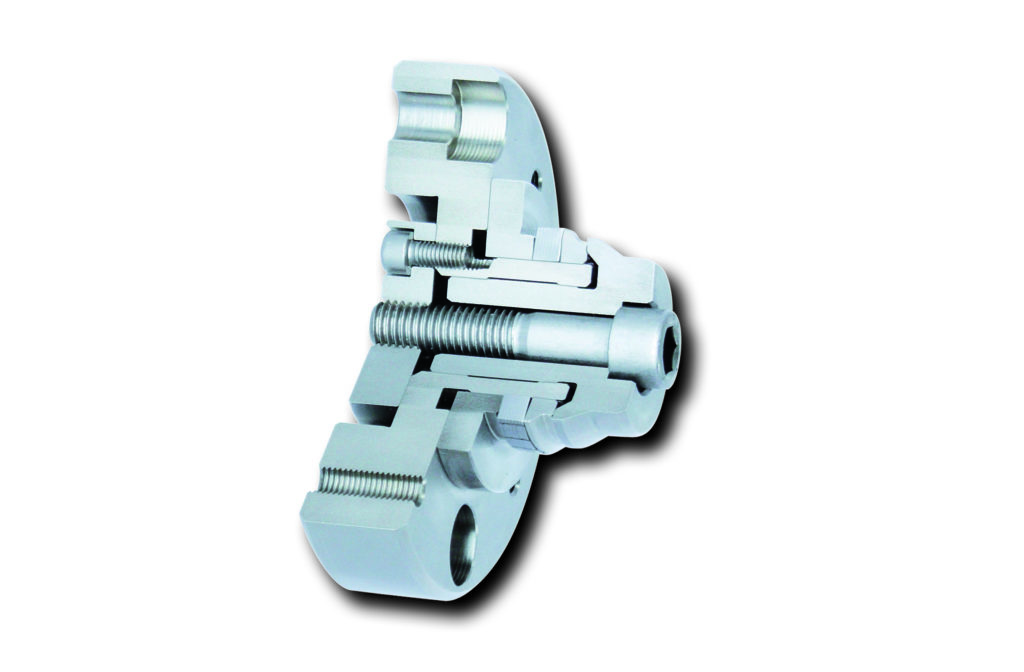

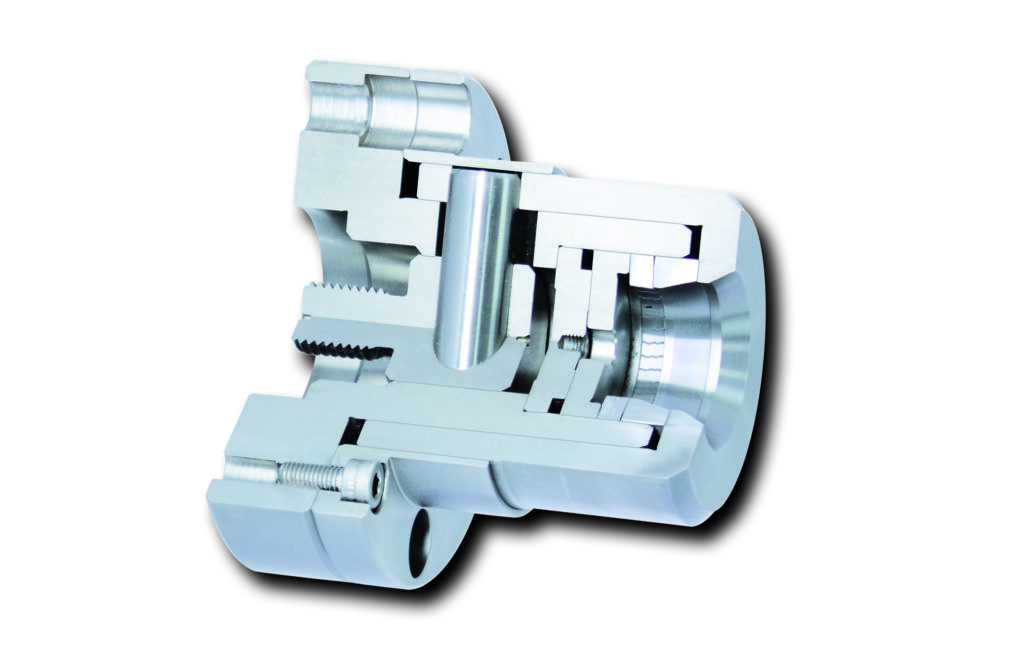

From our U.K. base in Bedford we specify, design and supply precision clamping chucks, taper collet mandrels, clamping clutches, diaphragm chucks, hydraulic mandrels chucks and much much more. Our staff are highly trained in the key areas of each product division to give the customer the best possible response to technical, commercial or general queries.

Our vastly experienced external staff are conversant with a huge array of applications and can ensure the right product is selected and supplied every time on time. So if you have a requirement for, or a problem with a work holding application, RINGSPANN can help quickly and efficiently with a lowest total cost of ownership solution.

Relentless investment in I.T., leading products and services, continuous improvement and personnel development enable RINGSPANN to produce the most cost effective work holding solutions on a truly global scale.

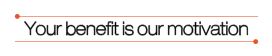

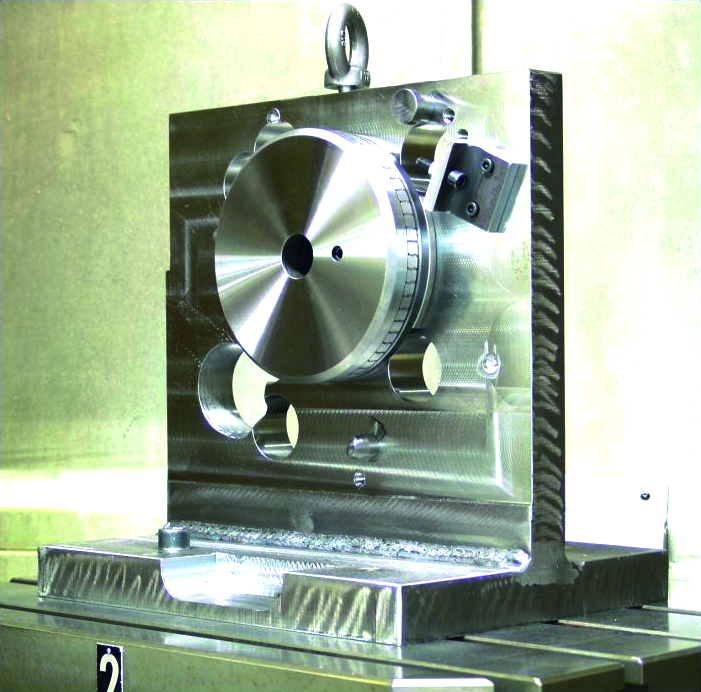

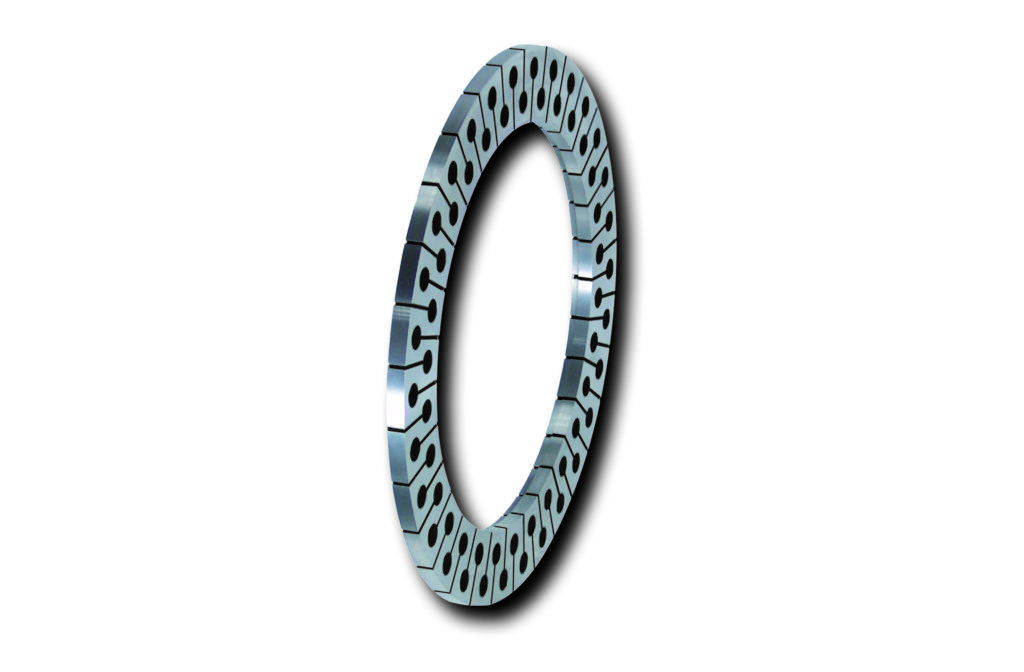

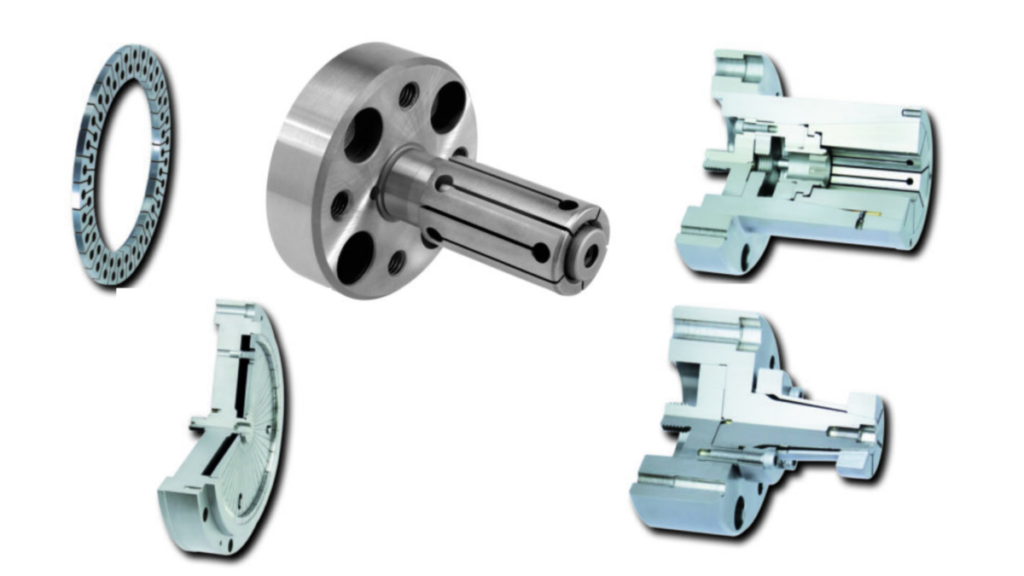

RINGSPANN specialises in clamping and centralising on cylindrical internal and external surfaces. Typical components include automotive, industrial gear and aerospace components. The RINGSPANN system is based on the RINGSPANN clamping disc which encompasses: – Complete clamping fixtures, Clamping elements and components for customer assembled clamping fixtures along with clamping principles for custom clamping devices. Originally invented in 1944 this technology has truly stood the test of time.

Common applications include, Planetary gears, Turbo charger housings, Aerospace Turbine discs, Die cast aluminium housings and composite tubes to name but a few.

The RINGSPANN system offers the right solution for each clamping application and guarantees maximum clamping precision without the need for complicated alignment. This enables customers to achieve difficult objectives such as clamping in short lengths or clamping thin walled components that are susceptible to deformation with unparalleled repeatability.

As well as the RINGSPANN clamping system we are also the exclusive U.K. supplier for KOENIG hydraulic clamping systems and we have the capability to design and supply hydraulic mandrels and chucks for the most demanding of applications.

RINGSPANN are also the exclusive U.K. distributor of BERG & Co GmbH Spanntechnik and are able to offer their solutions including Zero Point clamping systems, Tool grippers and press clamps from BERG’s formidable range of products.

With full design capability working in both Siemens NX and Pro Engineer RINGSPANN can offer total solutions from concept design to delivery working in partnership with the customers design, project and commercial teams.