Injection Moulded Enclosures for Electronics: Why Bespoke Beats Off–the–Shelf

Estimated reading time 2 minutes

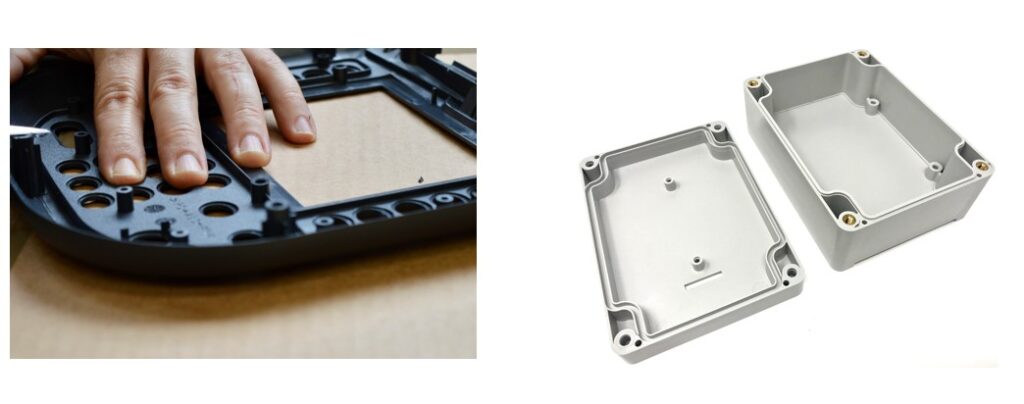

Generic plastic enclosures appear to be the sensible choice when you’re developing electronic products. They’re available immediately, cost less upfront, and solve the basic problem of housing your components.

However, simplicity often creates hidden costs that don’t surface until production increases.

Custom injection moulding addresses these problems by creating enclosures designed specifically for your electronics, your brand, and your market requirements.

The investment usually pays back through improved assembly efficiency, better product reliability, and premium market positioning.

Why Generic Enclosures Create Hidden Problems

Standard enclosures weren’t designed for your product. They were designed for maximum compatibility with everything.

This can create some issues that plague cheaper products, such as the hottest component winding up next to your most sensitive chip. Or your main connector hiding behind a support post.

Custom injection moulding fixes this, ensuring components are precisely positioned to maximise form and function.

Meeting Regulatory Requirements Without Workarounds

Regulations for many products are not negotiable and impact design. For example:

- Medical devices need biocompatible materials

- Automotive and similar components must survive specific temperature ranges

- Industrial equipment requires dust and moisture protection ratings

- Food processing components demand materials safe for direct food contact

Custom enclosures ensure that specifications are met early in the design and manufacturing process, thereby ensuring regulatory approval without compromise.

The Cost Problem

Purchase price only tells part of the story with enclosures. Generic options look great on paper, but production often reveals different economics once you start building products.

The hidden expenses pile up:

- Assembly takes longer: Poor fit means more time per unit and more mistakes

- Products fail in the field: Inadequate protection causes quality issues

- Pricing is squeezed: Generic aesthetics mean competing on price

- Changes become expensive: Product updates need new boxes and fresh testing

Most manufacturers discover that total project costs paint a different picture than initial quotes suggest.

Getting Your Enclosure Decision Right

Generic enclosures are suitable for some applications, but they’re not necessarily the smart choice simply because they cost less upfront. Your decision should consider how the enclosure affects assembly speed, product reliability, brand perception, and future product development.

We help manufacturers evaluate these trade-offs honestly. We’ve seen both approaches work and fail depending on the specific situation.

Got electronics that need proper housing? Contact BEC to discuss your requirements. We’re always happy to discuss and advise.