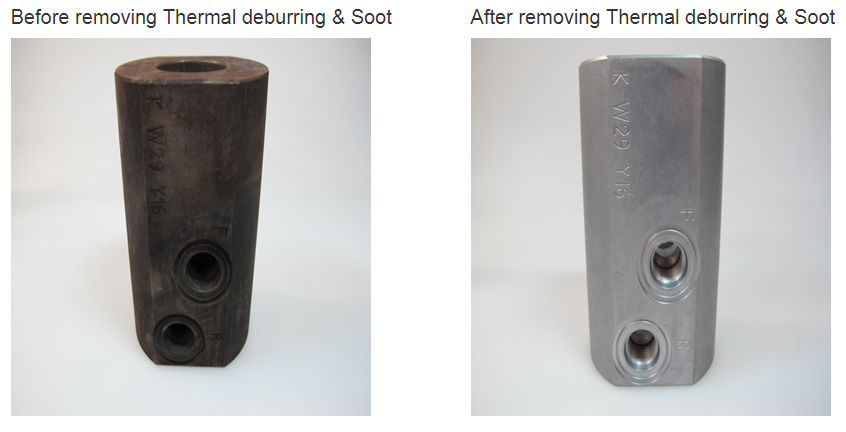

Cleaning after Thermal Deburring with an Ultrasonic Cleaner

Estimated reading time 1 minute

Process for cleaning after Thermal Deburring:

Process: One part was cleaned individually initially to test if the Rodastel 30 cleaning fluid was compatible and efficient. Wash: Four parts were then placed in the basket and set for a cycle time of 5 minutes, after you can see the black contamination has been completely removed. Next the parts were cleaned in a second wash tank using Galvex 17.30, this fluid acts as a anti corrosion inhibitor and coats the parts with a hydrophobic layer as well as neutralize the part from the previous acid used. Rinse: The parts were then rinsed in de-ionized water for 2 minutes to remove any left on debris. Drying: Finally the parts were then dried in a hot air dryer for 10 minutes at 70°C.

Note: Depending on the size and the amount of parts you aim to clean process parameters may vary.