CyTec Systems UK are pleased to offer new servo linear actuators SLA series & SMC control units from Servomold

Estimated reading time 3 minutes

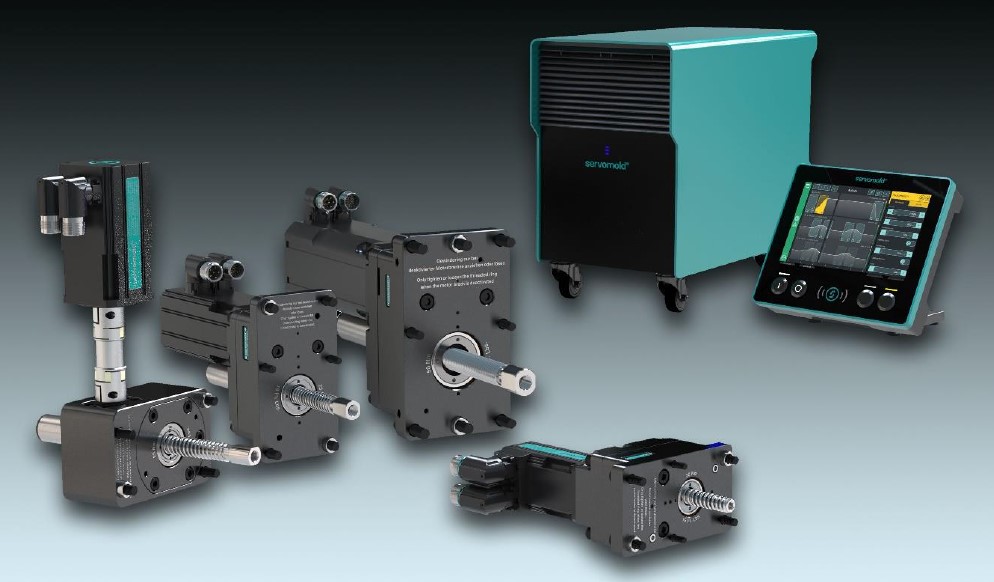

For long-term reliability, 100% precise and powerful execution of linear movements in injection mould tools, Servomold has developed the new servo linear actuators of the SLA series as well as the equally new compact servo worm actuators of the SSA series.

They offer high-performance as well as clean, oil-free, and thus optimally cleanroom-suitable alternatives to hydraulic and pneumatic cylinders traditionally used to perform translational slider, core, or platen movements in injection mould tools.

The actuators, which are suitable for both new moulds and retrofit applications, are available at short notice in performance classes from 4 kN to 50 kN. Special solutions with thrust forces up to 150 kN and rust-proof versions are available on request.

The SLA types are available in five sizes. The three smaller actuators are equipped with ball screw spindles as standard but can also be optionally supplied with roller screw spindles that can withstand higher loads over longer periods. The two larger versions are available solely with roller screw spindles. To achieve even higher forces or to equalize the force distribution, the SLA variants can be equipped with several spindles according to customer specifications. The SSA servo worm actuator, which is available in only one size, has a particularly flat design with a 90-degree arrangement of the drive unit. The specific ball screw and roller screw spindles can be configured with pitches of 2, 5 or 10 mm in any length for up to more than 1000 mm stroke. All versions offer high nominal thrust forces thanks to an integrated gear stage, which can be supplemented by an additional planetary gearbox.

In addition to precise positioning and repeat accuracy, their common advantages include permanently high forces and speeds, which are realized regardless of the process status. The movement profiles can be freely and individually defined and called up via the Servomold control units to optimize the sequences in the injection molding process. For the mould, controlled and gentle movements mean

less wear, higher availability, and significantly longer longevity. The easy interchangeability of the ball and roller screw spindles simplifies maintenance work.

In addition to the new linear actuators, the SMC (Servo MoldControl), a newly developed control unit generation for servo amplifiers that will be available on the market from 2024. Characteristics are the intuitive operability via the uniformly used touch panel as well as the automatic switching between different encoder systems. In addition to servo-electric single to fourfold unscrewing units and worm unscrewing units for unscrewing threads, this also includes complete unscrewing halves ready for operation, high-performance servo drive units, space-saving indexing plates that can be integrated, thread core sets and rotating thread core cooling systems for unscrewing devices.

Further information: https://servomold.com/en/landingpage-smc

CyTec Systems UK

sales@cytec-uk.com

0161 6787090

www.cytecsystems-uk.com