Dayton Progress Introduces DAYComp: Increased Durability and Efficiency in Toolmaking

Estimated reading time 2 minutes

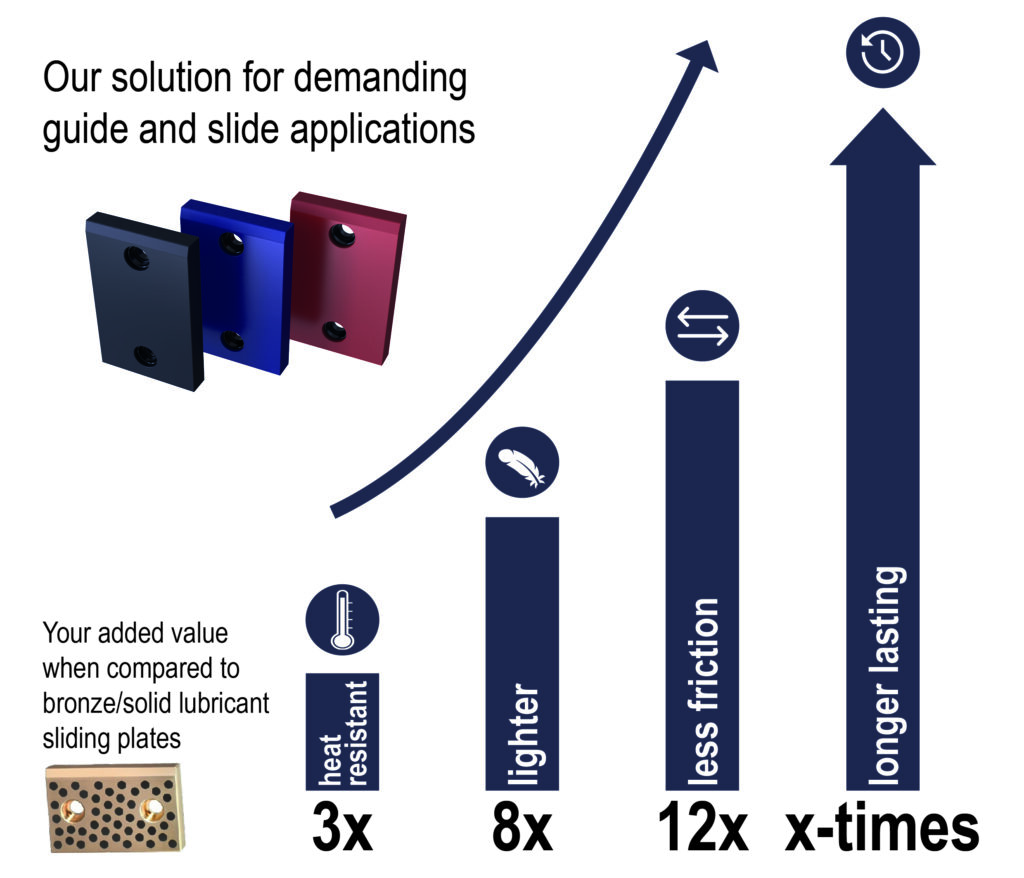

Enhancing Efficiency and Sustainability with Innovative Composite Material Sliding and Guide Elements

Dayton Progress, a leading company in the development and manufacturing of precision tools, today introduces DAYComp, an innovative product line of sliding and guide elements made from composite material, specifically designed to meet the challenges of cold and hot forming processes.

Frederick Wilkinson, Managing Director of Dayton Progress Europe, states, “DAYComp sets new standards in terms of durability, efficiency, and sustainability in toolmaking.”

The Added Value for You: Significant Improvements in Performance and Sustainability

Compared to traditional sliding and guide elements made from bronze with solid lubricant, DAYComp offers:

- 3x higher heat resistance

- 8x lighter weight

- 12x lower coefficient of friction

- X-times increased lifespan

The Challenge

The manufacturing industry faces the issue that conventional sliding and guide elements are not always able to meet the demands of cold and hot forming under certain conditions. The limited lifespan of these components, coupled with the need for regular replacement, leads to high costs and productivity losses.

The Solution: DAYComp

DAYComp, the result of intensive research and development, is a composite material specifically designed for extreme stresses. Its unique composition significantly reduces the coefficient of friction, minimizes abrasive wear, and increases the lifespan of components multiple times compared to existing solutions.

In addition to significantly improving product lifespan and reducing maintenance costs, DAYComp enables energy savings during operation due to its lighter weight. Production on the European mainland further contributes to CO2 reduction and supports companies in achieving their ESG goals. Moreover, DAYComp sliding plates are suitable as sliding partners for unhardened steel or cast iron, enabling further cost savings.

Custom Design Options and Exceptional Performance

The unique material properties allow the manufacture of wear products tailored to individual customer requirements. Dayton Progress is ready to analyze specific application conditions and offer customized solutions that increase productivity, reduce maintenance and repair costs, and contribute to CO2 reduction.

For more information about DAYComp and how it can improve efficiency and sustainability in your company, please contact Dayton Progress.

About Dayton Progress

Dayton Progress is a leading manufacturer of precision tools and components for the manufacturing industry. With over 95 years of experience, Dayton Progress is committed to innovation, quality, and customer satisfaction.

Contact:

DAYTON PROGRESS Ltd.

Unit F8b

Holly Farm Business Park Honiley

Kenilworth, Warwickshire CV8 1NP