Delcam’s latest CAD and CAM to debut at Northern Manufacturing

Estimated reading time 4 minutes

Delcam will give UK debuts to the 2015 versions of its PowerSHAPE Pro CAD and reverse engineering software, and its FeatureCAM and PowerMILL CAM systems at the Northern Manufacturing exhibition to be held at Event City, Manchester, on 1st and 2nd October. Each of the programs contains major enhancements that will help manufacturing companies to increase productivity, improve quality and reduce lead times.

By offering a combination of solid, surface and direct modelling, together with reverse engineering functionality, PowerSHAPE Pro provides the most comprehensive range of design techniques available in a single CAD program. Having all the different technologies in the same package reduces the need to transfer data between multiple programs and so streamlines the whole product development process. At the same time, the combination of quick and easy direct modelling options, together with powerful and flexible surface modelling, makes PowerSHAPE Pro the perfect choice for design for manufacture.

The main enhancement in the 2015 release is to the Smart Feature Selector which allows multiple similar features to be found and selected using either a specific value or a range of values. Once the particular group has been selected, all the features within it can be edited simultaneously. For example, all holes having a diameter of 5mm can have their diameter increased to 10mm in one operation.

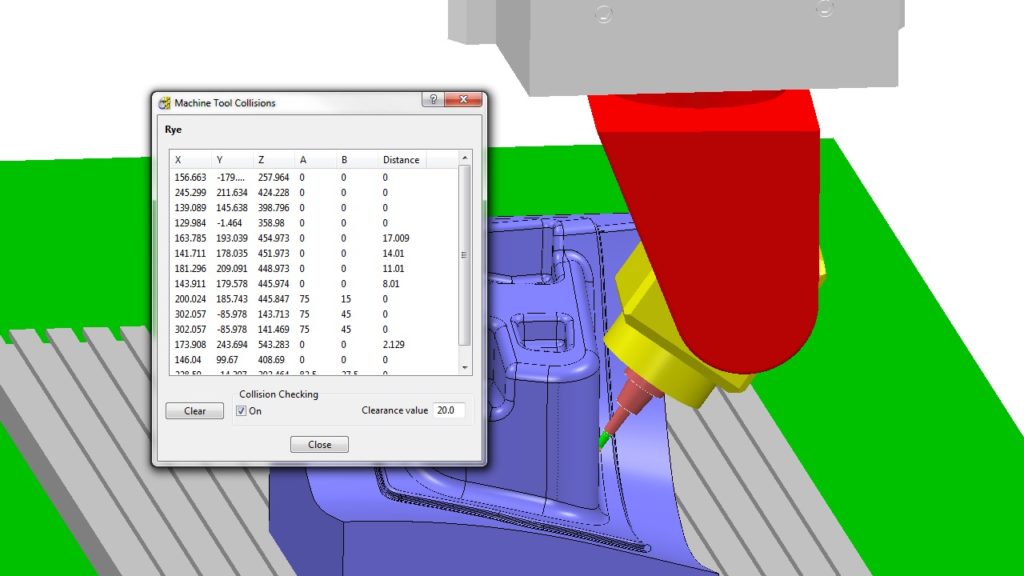

The new release of PowerMILL, Delcam’s programming system for high-speed and five-axis machining, includes improvements to the Vortex high-efficiency area-clearance strategy, expanded collision checking to also cover near misses, and more efficient raster finishing.

Vortex produces safe toolpaths with a much deeper cut by using a controlled engagement angle that maintains the optimum cutting conditions for the whole toolpath. As a result, higher feed rates and material-removal rates are possible, making the cutting time shorter by as much as 70%. In addition, cutting is undertaken at a more consistent volume-removal rate and at a near constant feedrate, so extending tool life and protecting the machine.

Two enhancements in PowerMILL 2015 will give even greater reductions in machining time with Vortex compared to conventional roughing. The first change allows toolpaths to approach the part from outside the stock at the cutting height for open pockets or in areas where earlier cuts have made this possible.

The second change allows an increased feed rate to be set for non-cutting moves. The default value is set at double the rate for the cutting moves but this can be altered as required for each machine tool. The extra time that can be saved depends on the shape of the part but an additional saving of around 20% should be expected above the earlier releases of Vortex.

FeatureCAM was the world’s first feature-based programming software when it was launched in 1995. Constant development since then has ensured that the system has retained its leadership in programming speed and ease of use, while an increased range of strategies has been added to provide more efficient toolpaths that give greater productivity on a wider range of machinery, including mill-turn machines, five-axis mills and wire EDM equipment.

FeatureCAM 2015 includes a range of enhancements in three-axis milling, two-axis and five-axis drilling, turning and turn-mill, and wire EDM to make the software even more powerful and easier to use.

FeatureCAM 2015 also allows easier programming of families of parts. Working with the part library, the software matches the names of features within the part library with user-created curves relating to those features. This makes the programming of subsequent parts in the family much easier and faster.

For further information on Delcam’s CADCAM software, please contact: –

Peter Dickin, Marketing Manager

Direct phone: 0121 683 1081 e-mail: marketing@delcam.com

Delcam Ltd

Small Heath Business Park,

Birmingham, B10 0HJ, UK

Caption: The improved collision detection in PowerMILL 2015 will be demonstrated at Northern Manufacturing