Delcam’s new PowerSHAPE Pro reverse engineering on show at TCT

Estimated reading time 3 minutes

At the TCT exhibition to be held at the NEC, Birmingham, on September 30th and October 1st, Delcam will demonstrate a series of enhancements to its PowerSHAPE Pro software for modelling and reverse engineering that will help users to complete complex designs more quickly and more easily. In addition, a combination of new, more efficient, code and the extension of multi-threaded calculations to many commonly-used tasks will make PowerSHAPE Pro 2016 significantly faster than any previous version.

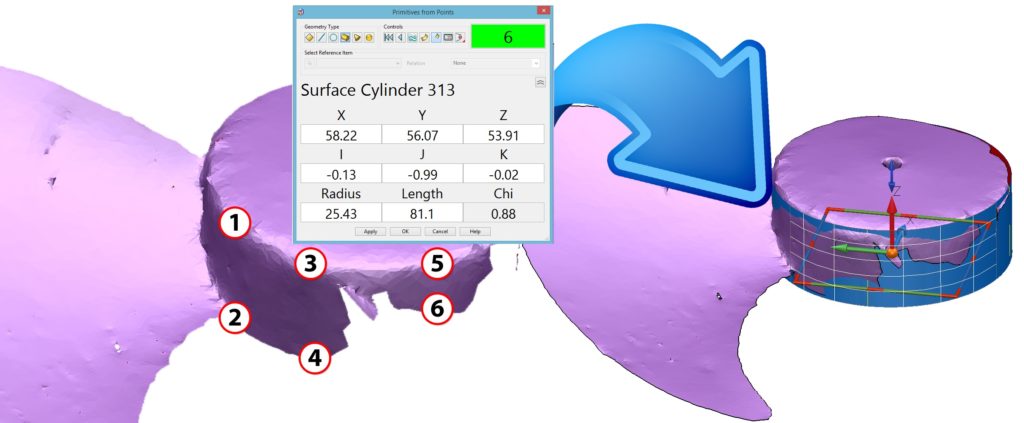

Caption: In PowerSHAPE 2016, reverse engineering of prismatic parts has been made easier

Full details, including video demonstrations, are on the Learning Zone – www.delcam.tv/ps2016/lz/en

By offering a combination of solid, surface and direct modelling, together with reverse engineering, PowerSHAPE Pro provides the most comprehensive range of design techniques available in a single CAD program. Having all the different technologies in the same package reduces the need to transfer data between multiple programs and so streamlines any modelling-for-manufacture projects that require both reverse-engineering and CAD functionality.

PowerSHAPE Pro can connect directly to most scanning hardware to capture and display scan data in real time. In the 2016 release, it has been made possible to switch between measuring modes when using devices that offer data collection by both laser scanning and point probing.

A split-screen alignment option makes it quick and easy to combine multiple scans, taken, for example, from the opposite sides of a part. The method allows accurate snapping of alignment points, ensuring that the resultant single CAD model is a good representation of the scanned object.

Reverse engineering from probed points is now possible for prismatic parts, with a new ability to identify planes, cylinders, cones and other primitives, or to create wireframe arcs and lines, directly. This approach is usually faster and can often be more accurate than using scan data to create prismatic areas of a model.

PowerSHAPE Pro also has the ability to replace regions of complex, free-form geometry with a single, shrink-wrap surface. In the new release, it has been made easier to re-orient such surfaces interactively and so place them in the most appropriate surface alignment.

Another recent option is the ability to morph a complete solid or surface model to a mesh. This can be used to compensate for spring-back when pressed parts are released from their tooling. Morphing can be used to update a nominal CAD model to match the part as it is made in reality or to modify the surfaces of the tool so that the part can be produced in the desired shape represented by the CAD model.

PowerSHAPE Pro includes many tools to clean up reverse-engineered models to ensure that they represent the design intent accurately. For example, features that are intended to be identical, such as a series of holes, will often show small variations when recreated from scan data. In such cases, all similar items within a specified tolerance band can be selected automatically in PowerSHAPE Pro and then all adjusted together to the same precise size. Similarly, the axis direction of a group of primitives that are not aligned exactly can be brought into alignment in one operation.

For further information on Delcam’s PowerSHAPE Pro software, please contact: –

Peter Dickin, Marketing Manager

Direct phone: 44 (0)121 683 1081 e-mail: marketing@delcam.com

Delcam Ltd

Small Heath Business Park,

Birmingham, B10 0HJ, UK