Enhance Your Hardness Testing Capabilities with Advanced Technology

Estimated reading time 2 minutes

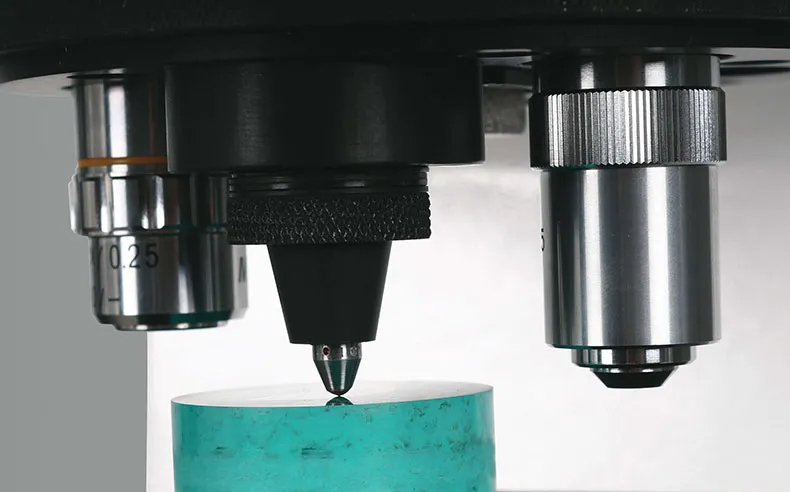

Accurate and efficient metallographic sample preparation is crucial for revealing the true structure and quality of metal samples, directly impacting the effectiveness of hardness testing.

Hardness testing is a vital process in various industries, including academic research, automotive and aerospace manufacturing, as well as in the evaluation of coatings and surface treatments. Reliable hardness measurements are essential to ensure the quality and durability of finished products.

However, choosing the right hardness tester from the vast options available can be overwhelming, with some testers costing more than a complete sample preparation system. Ensuring compliance with ISO and ASTM standards for hardness testing and calibration is key to streamlining the process and achieving accurate results.

To address this need, Kemet introduces the Duroline series of benchtop hardness testers. Featuring a 22″ full HD multi-touch monitor, these testers support Vickers and Knoop hardness testing. The intuitive N-sure software, combined with an automated x/y stage, offers automated multi-measurement functionality for enhanced efficiency. With built-in CHD, EHT, and NHT measurement capabilities, it delivers precise results and generates automated test reports.

Ideal for materials testing laboratories and smaller quality assurance departments, the Duroline series offers models with test loads ranging from HV0.01 to HV30, perfect for testing small precision components, thin materials, or wire coatings.

For more information, please contact sales@kemet.co.uk.