Faulkner Moulds ‘UK-First’ Technology for Multi-Cavity High Production Toolmaking

Estimated reading time 2 minutes

Award-winning UK Toolmakers, Faulkner Moulds has again installed trail blazing technology at their Yorkshire-based toolroom.

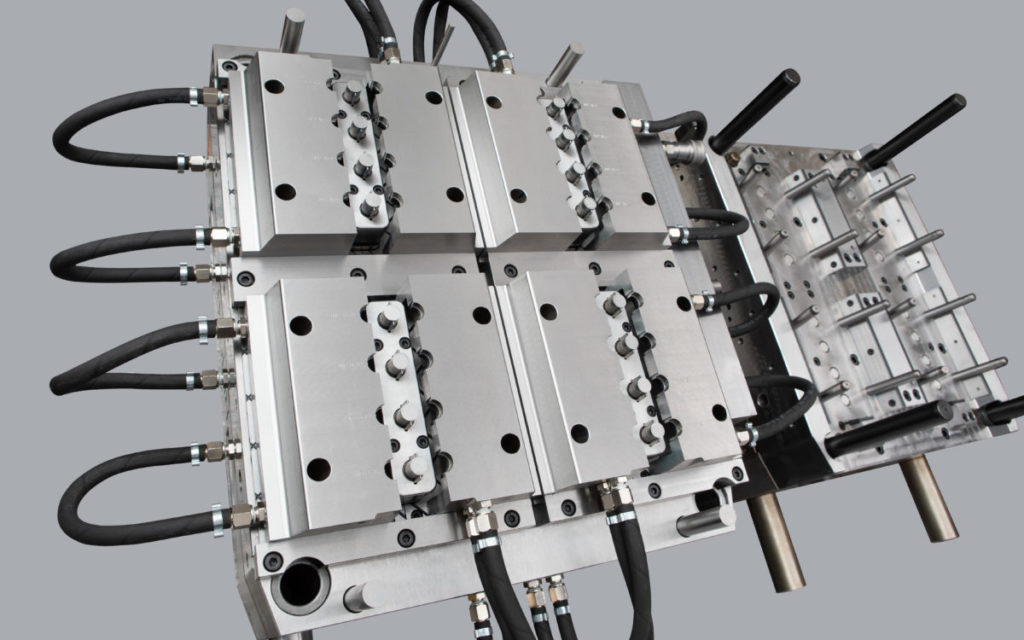

Their innovative robotic production cell is a ‘UK-first’, further enhancing the quality and efficiency of their mould tool manufacture. The production cell particularly supports multi-cavity, high-production tooling.

The pioneering manufacturing cell will feed both the Mikron 5-Axis and Sodick spark erosion machines, enabling automated changes of electrodes and of workpieces, further increasing capacity for high cavity tooling, of which Faulkner Moulds has sound experience.

For example, the tool pictured has 16 impressions, is guaranteed for a million shots and moulds at an efficient 7 second cycle time. Faulkner Moulds recently reduced the cycle time on a new 12 impression packaging tool for a household name, from a target of 8.5 seconds to just 6.98 seconds.

Faulkner Moulds’ Managing Director, Duncan Faulkner says, “Our success lies in focussing on 3 things – customer service, skills and training, and technology. We never stay still – we are constantly innovating and finding ways to move forward for our customers”.

This year, the three-times UK ‘Toolmaker of the Year’ winner has also taken delivery of a new Hurco TM8i 2 axis CNC turning centre (lathe) and Mitutoyo Crysta-Apex S CNC Co-ordinate Measuring machine.

The CMM machine responds to increased demand for ever tighter tolerances in toolmaking, allowing highly accurate 3D measurements at high speed. Dedicated software algorithms guarantee high accuracy by eliminating even miniscule geometrical imperfections in the guideways.

The versatile turning centre has in-built features to ease programming, enhance machine speed and ensure outstanding accuracy and surface finish. It is ideally suited to the fast-paced demands of modern toolmaking. Faulkner Moulds’ recent experience in high precision turning includes projects for the medical, packaging and industrial sectors.

Other recent investments include a new wire erosion machine and a new CNC sparker that runs to a guaranteed 3 microns accuracy all day.

The three newest machines are already in daily use, helping Faulkner Moulds respond to increased demand for high precision multi-cavity toolmaking and extreme measurement accuracy.

01422 371072