Innovative Collaboration Between Elesa and Metallic Elephant Sets New Standards in Hot Foil Press Technology

Estimated reading time 3 minutes

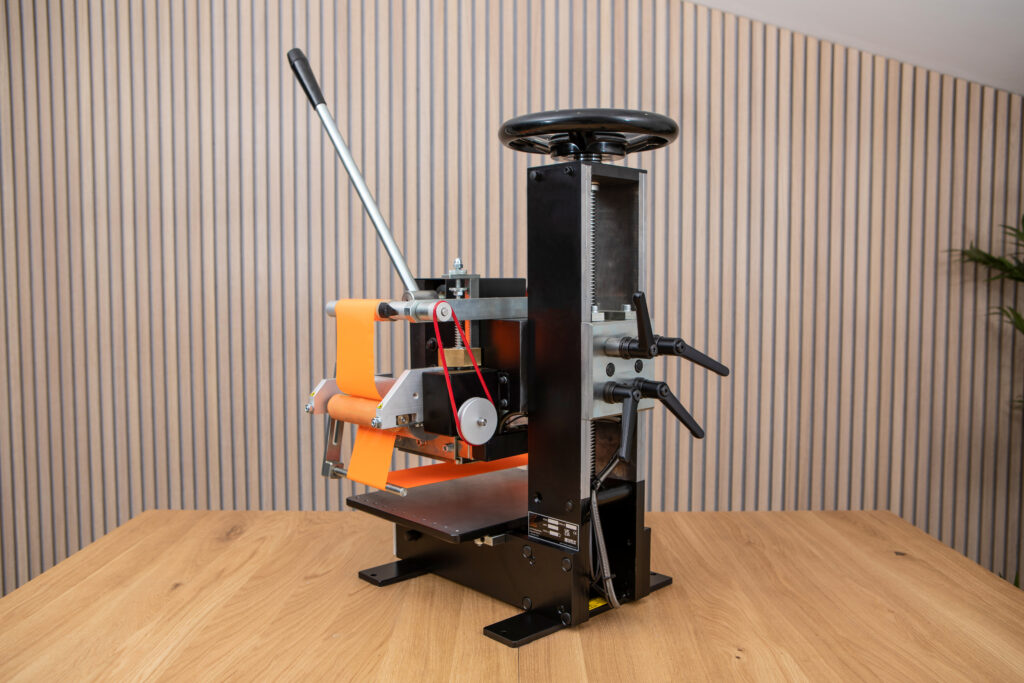

In a landmark partnership, Elesa, a renowned provider of high-quality engineering components, has collaborated with Metallic Elephant, a leader in hot foil machinery manufacturing, to unveil a ground-breaking hot foil press. This innovation redefines industry benchmarks for quality and efficiency.

For over 17 years, Metallic Elephant has been at the forefront of the hot foil press sector, creating sophisticated machinery for diverse industries. The drive to develop a distinct product delivering unparalleled performance and reliability spurred the search for a partnership with Elesa, whose values of innovation and quality mirrored their own.

Elesa is celebrated for its precision-engineered components that enhance operational excellence across various applications. Their commitment to producing adaptable, high-quality products that satisfy rigorous industry standards made them the ideal partner for Metallic Elephant’s ambitious initiative.

This collaboration addressed significant challenges previously encountered with suppliers whose components did not meet durability standards, causing production inefficiencies and increased costs. Integrating Elesa’s reliable and precisely engineered components enabled Metallic Elephant to overcome these hurdles, ushering in a new era of hot foil press design and functionality.

The partnership yielded a state-of-the-art hot foil press distinguished by its innovative design and operational capabilities. Featuring advanced elements such as adjustable handles and quick-release mechanisms, the press is user-friendly and versatile. It accommodates various product sizes and specifications effortlessly, with a design that supports quick adjustments and scalability—considerable enhancements over prior models that boost its competitive edge.

Utilising Elesa’s components has markedly improved the performance and reliability of Metallic Elephant’s presses. Notable advancements include a 20% increase in assembly speed and a substantial decrease in production errors. These improvements have led to a more efficient manufacturing process, enhanced product quality, and heightened customer satisfaction. Additionally, the presses’ enhanced longevity and reliability have bolstered client confidence in their investments, promising longer lifespan and reduced operational costs.

This partnership has not only resolved initial challenges but also set new standards for quality and efficiency in hot foil press engineering. The collaboration between Elesa and Metallic Elephant demonstrates how strategic alliances can foster innovation and deliver superior products that benefit the entire industry. Looking ahead, both companies are committed to further enhancing their product lines and continuing their successful partnership. Driven by a shared goal to exceed customer expectations and push technological boundaries, this ongoing collaboration is poised to introduce more innovative solutions to the market, highlighting the importance of merging engineering and manufacturing expertise to achieve outstanding results.