MaxiMill – S-Power glides through cast iron thanks to its high tooth count

Estimated reading time 3 minutes

Efficient milling of cast iron with MaxiMill – S-Power from CERATIZIT

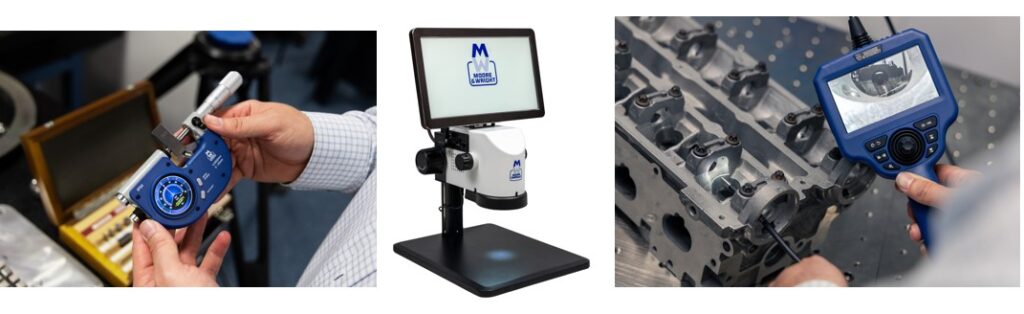

Cast iron machining can be tricky, with issues like heavy tool wear, extreme burr formation and breakouts on workpiece edges potentially jeopardising efficiency. This is where the milling cutters in CERATIZIT’s Maximill – S-Power series come in. With a high tooth count and double-sided indexable inserts, the system offers optimal performance and a highly stable, low-vibration construction. What’s more, an innovative double wedge clamp also ensures that the indexable inserts are easy to use and securely attached.

Machining cast iron components can represent a huge challenge for many fabricators, with issues like burr formation and breakouts on the workpiece edges forcing many users to settle for low feed rates. This unnecessarily extends production times and can cause efficiency to be neglected. “With the MaxiMill – S-Power, it’s a different story. Its optimal number of cutting edges (12 teeth with Ø63 mm) and the positive cutting edge design not only enable higher feed rate values, but they also improve the surface quality and reduce burr formation. Anyone who machines braking systems or mounting surfaces of high-performance motors are among those who will benefit from the enhanced performance of the new milling system,” says Robert Frei, Technical Product Manager at CERATIZIT.

MaxiMill – S-Power unleashes the maximum number of teeth

The milling cutters in the MaxiMill – S-Power series boast an impressive number of cutting edges. But how does it all work? The setting angle of 88° enables a high tooth count and small chip spaces. Double-sided indexable inserts with eight actual cutting edges made from selected substrates and with DRAGONSKIN coatings ensure high performance with a smooth cutting action. The sturdy construction with robust insert seat and double wedge clamp guarantees a secure hold and high axial and radial run-out accuracy.

The wedges are fitted with anti-twist protection and there are separate clamping wedges for each holder diameter, in order to ensure optimal clamping. Furthermore, the double-sided wedge clamping makes it easy to quickly and accurately change inserts as there is a single screw for each double wedge.

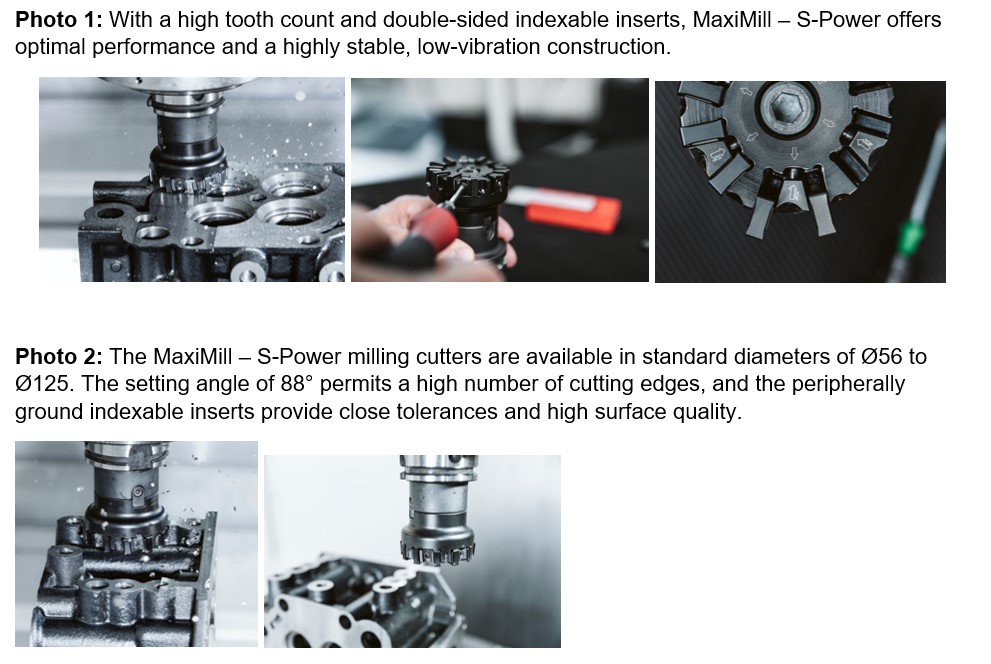

The MaxiMill – S-Power milling cutters are available in standard diameters of Ø56 to Ø125. The setting angle of 88° permits a maximum number of cutting edges, and the indexable inserts are peripherally ground for close tolerances and a high surface quality. The indexable inserts are thicker than conventional inserts, which makes them extremely sturdy.

Machining flow in cast iron

MaxiMill – S-Power complements the existing face milling systems from CERATIZIT and is ideal for cast iron components made from GJS, GJV and GJL. A maximum depth of cut of around 8 mm and reduced feed rate values between 0.08 mm and 0.15 mm minimises breakouts on the casting wall, while maintaining high efficiency thanks to the high number of teeth.

The range of indexable inserts includes ISO P/K with cutting edge geometry M and offers corner radii of 0.4 mm, 0.8 mm and 1.2 mm. The grades include CTPK220, CTCP230 and ceramic.