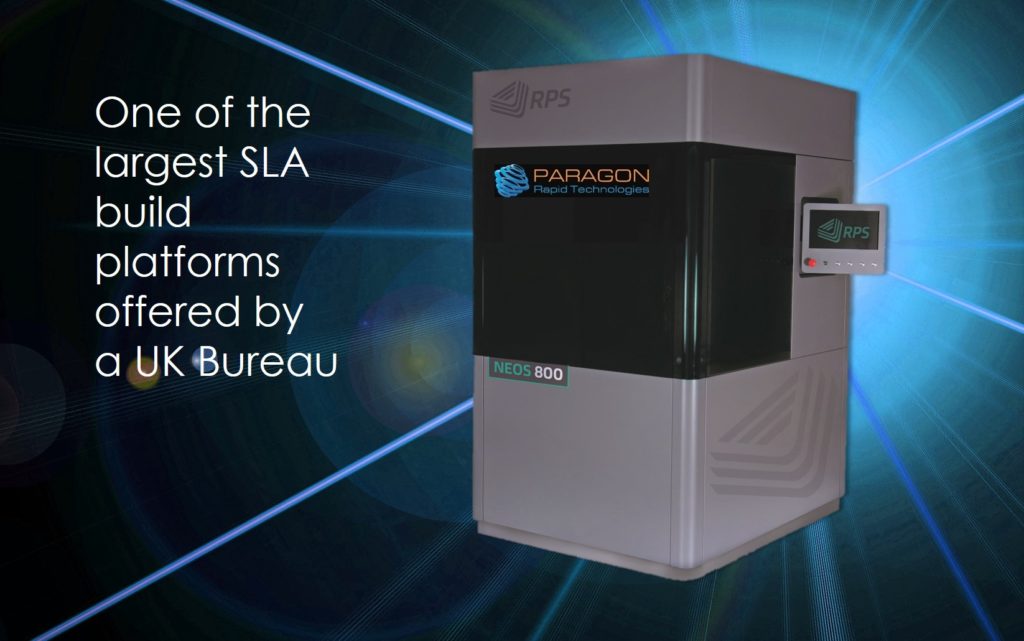

Paragon GO LARGE with 800mm SLA High Definition Solution

Estimated reading time 2 minutes

Until recently UK manufacturers have been limited to smaller Stereolithography build platforms for their 3D printing applications and the only way to produce big prototypes was by section and bond methods. However Paragon has taken the plunge and invested in a large frame SLA machine with a build platform of 800mm x 800mm x 600mm – one of the largest offered by a 3D Print Bureau in the UK. The NEOS 800 machine was designed and manufactured in the UK by RP Support using next generation software and laser technology, building in rapid HD format to reduce finishing and delivery times significantly.

The new machine will run WaterShed® 11122, which produces nearly colourless parts that look more like true, clear engineered plastic components. In addition, this resin has been formulated with the DSM Somos Oxetane Advantage™— an advanced chemistry platform that produces parts with outstanding water resistance and high dimensional stability.

Paragon’s new Commercial Director Ian Jobling said, “The 3D printing market is becoming saturated with small printers and start-up companies offering models, but very few RP organisations have the size and investment capital to GO LARGE. I am delighted that Paragon have both and this means we can now offer the market rapid HD SLA printing on a big scale for the first time. Our new machine caters for customers who want to build models up to 1m in length in one single piece. We have already seen significant interest in this new solution and delivered a number of exciting projects to National and International clients.”

Visitors to Stand E31 at this year’s Advanced Engineering Show between 2-3 November 2016 at the NEC in Birmingham will have the opportunity to see some printed samples from the new machine. Call +44 (0)1325 333141 for more information, or email Ian directly at ian.jobling@paragon-rt.com.