Quick Solution To Material Removal With New End Mill Innovation

Estimated reading time 4 minutes

The rise of innovative 5-axis machining strategies from leading CAM vendors that focus upon maximum material removal rates has seen cutting tool manufacturers slip behind the curve with respect to tool geometry developments for such strategies. That was until Quickgrind launched its ground breaking Eliminator Series of end mills.

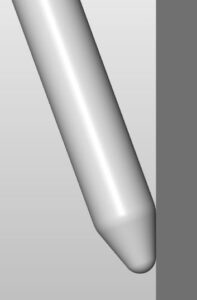

Referred to as conical barrel tools, the new series of Eliminator end mills for 5-axis machining incorporate a conical or tapered form that will deliver a cycle time reduction of up to 95%. This bold claim is substantiated by the ability of the Eliminator to significantly reduce tool path distances whilst utilising the full flute length to increase the step down rate and the subsequent material removal rates.

From an application perspective, the new Eliminator conical barrel tools are suited to semi-finish and finish machining processes on a wide range of components and materials that span the mould & die, motorsport, medical, oil & gas and particularly the aerospace sector and turbine blade production. The solid carbide end mills are available uncoated or with Quickgrind’s Type D geometry with an MX coating for the machining of low and medium alloy steel, tool steel, cast iron and hardened steels whilst the Type S end mills are XRED coated for the high performance machining of high temperature alloys such as Inconel, Hastelloy and Titanium as well as the complete range of stainless steels.

To benefit from such huge cycle time reductions, manufacturers must first be utilising 5-axis machine tools and Quickgrind recommends that secondly, machine shops are implementing groundbreaking machining strategies from leading CAM vendors. To investigate the best exploitation of machining strategies, Quickgrind can offer support through its QuickCAMPro engineering service.

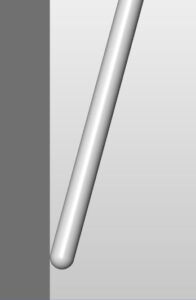

The highly flexible conical barrel tools can be used as a direct replacement for ball nose and standard end mills that are used for scanning, profiling, pocket milling and machining hard to access surfaces. This multi-purpose solution offers customers complete side machining as well as ball nose cutting. From a performance perspective, the tool paths and step-over rates will deliver unparalleled benefits whilst the ball and side cutting geometry will reduce tool inventory requirements for end users. Furthermore, the unique Quickgrind Eliminator geometry reduces the potential for thermal deformation, dissipating the heat from the cutting edges with maximum efficiency. This extends tool life drastically and simultaneously improves surface finishes and the consistency of the end mill performance.

How it works…

The Eliminator conical barrel end mill takes an area of a circle to form the radius of the flute, which improves the step down strategies when compared to ball nose end mills. Until now, the conventional way to produce a finish was to use a ball nose, which limits the step down that is generally calculated as: ap= 0.02 X D1. As an example, a 10mm diameter ball nose can achieve an ap of 0.20mm. To increase this step down would require a much larger diameter tool that simply isn’t practical.

The contact area of the conical barrel tool is much greater because the flute radius is adapted from the segment of a much larger circle. If you wanted to increase the step down from 0.2mm to 5.0mm you would need a 250mm diameter ball nose. However, by taking a segment of a 250mm diameter circle to form the flute of your tool, you can achieve a tool diameter from 6mm to 16mm.

The contact area of the conical barrel tool is much greater because the flute radius is adapted from the segment of a much larger circle. If you wanted to increase the step down from 0.2mm to 5.0mm you would need a 250mm diameter ball nose. However, by taking a segment of a 250mm diameter circle to form the flute of your tool, you can achieve a tool diameter from 6mm to 16mm.

The Eliminator series is available as a 3 or 4 flute tool. The three flute and four flute end mills are offered with a shank diameter of 6, 8, 10, 12 and 16mm that respectively tapers down to a ball nose diameter of 1, 2, 3 and 4mm with a flute radius of 250, 500, 1000 and 1500mm. These end mills are provided with an overall length from 58 to 93mm with a tapered flute length from 9.5 to 31mm. Quickgrind pride themselves on offering the best tool for the job and offer a quick turnaround for bespoke tools designed to suit the customers application. In this respect Quickgrind can also offer tools with 2 flutes or a flute radius of 15,000mm and have produced tools of 1.80mm Dia with R0.80 ballnose. For further details on how Quickgrind can revolutionise your 5-axis machining strategies and performance with its UK manufactured cutting tools, contact Quickgrind on: 01684 294090.