Rotalink Ltd Ensures Concentricity of Precision Gears with Measuring Machine from Bowers Group

Estimated reading time 3 minutes

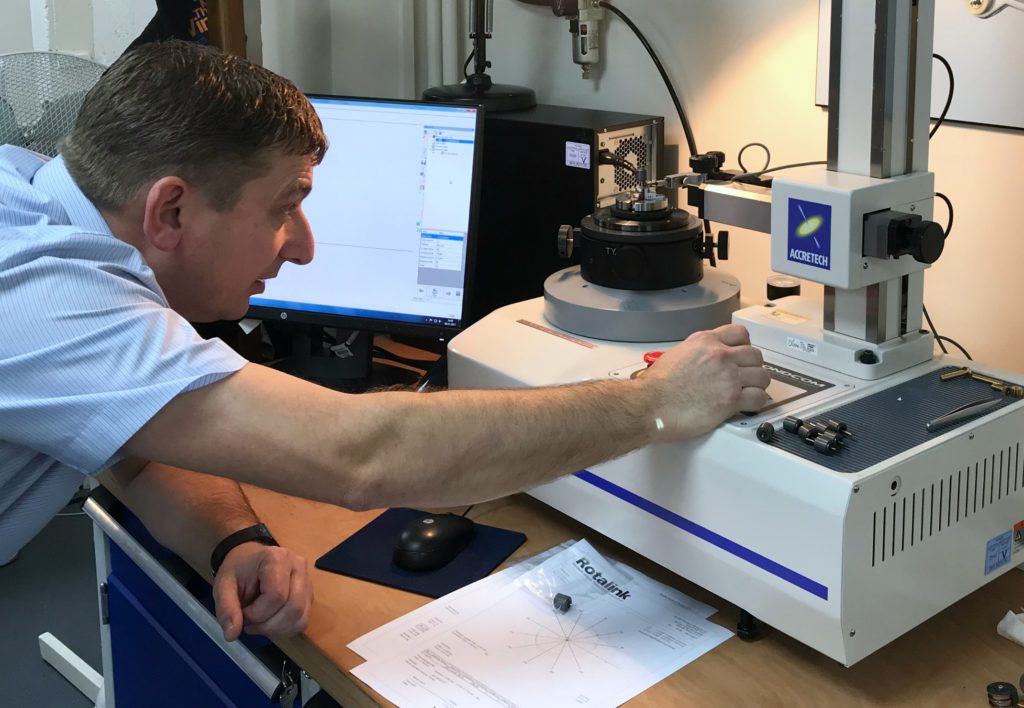

Metrology expert Bowers Group has supplied Rotalink Ltd with an Accretech Rondcom 41C for the precision measurement of miniature power transmission systems and motor gearboxes. Based in Crewkerne, Somerset, Rotalink Ltd required an accurate and repeatable measurement solution for the concentricity of spindles and shafts, in order to consistently meet high standards of quality and exceptionally tight tolerances required of its components.

Bowers Group suggested a roundness measurement instrument as an appropriate solution to measure the concentricity of moulded gears at Rotalink Ltd. After a full demonstration at Rotalink Ltd’s Crewkerne site, Bowers Group supplied the business with the Accretech Rondcom 41C, a roundness measuring instrument which enables the fast, easy and accurate implementation of form measuring tasks; including concentricity.

The Accretech Rondcom 41C also features excellent straightness accuracy, which was particularly important for Rotalink Ltd. The accurate measurement of squareness to a plane is critical in the high quality manufacturing of precision gears.

The Rondcom has enabled Rotalink Ltd to improve the accuracy of its manufactured components, and therefore improve their products. As a company with an innovative design team, the roundness measurement machine has enabled Rotalink Ltd to ensure the accuracy of each design; not only improving manufactured components, but also improving drawings and design capabilities. Software reports generated by the Rondcom are useful for internal reports and can also be used as valuable evidence for ISO inspection reports.

Jeremy White, Quality Engineer at Rotalink Ltd said: “There are now endless possibilities when it comes to ensuring the accuracy of each design and component at Rotalink Ltd. As far as concentricity is concerned, the Accretech Rondcom 41C is exceptionally accurate, and comfortably nudges ahead of rival machines.”

Rotalink was also impressed by the service they received from Bowers Group. Jeremy continued; “We received excellent initial training and installation from Ryan Kingswell, Technical Support and Installations Engineer at Bowers Group. Since we’ve had the Rondcom, we’ve learned even more about its capabilities; the more you use it, the more operatives understand the full measurement capacity of the machine.

We decided to choose the Rondom 41C for several reasons. One was the cost comparison to other models and the capabilities of the 41C compare to others. Another advantage was that the Rondcom could be fully integrated into our computer network. Ryan really worked his socks off to ensure that the integration was successful, working closely with our IT department to ensure full integration. The Rondcom is definitely an asset to the business!”

Rotalink Limited supplies miniature power transmission systems, motor gearboxes, encoders, controllers and more to a global network of customers. The company prides itself on being a centre of excellence for the design and supply of miniature power transmission products, including DC motors with optional gearboxes, AC motors with optional gearboxes, and stepping motors with optional gearboxes. The motors and gear cases designed and manufactured by Rotalink Ltd are commonly used in a variety of applications, including cash machines, parking meters, vending machines, coffee machines, and lubrication systems, among others.

Philip Stag, Purchasing Manager at Rotalink Ltd said: “The Accretech Rondcom 41C performed very well under the criteria we set out, fully meeting our requirements and more. We were very impressed with the Bowers Group staff members involved; they had a great deal of knowledge and we received excellent training and aftersales support. They were more than willing to visit and develop a good relation with us, giving us plenty of confidence in the product and their customer service.”