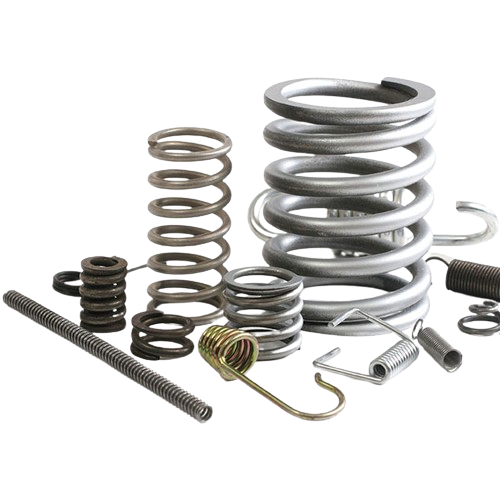

Springs Are Everywhere – And They Need Testing

Estimated reading time 2 minutes

Overall, compression and tension testing of springs are fundamental to ensure they perform as intended, maintain safety standards, and meet the specific requirements of their applications.

The main requirements are selected from the following parameters according to the product and test requirements, performance verification, material properties, design validation, safety assurance, quality control, compliance and standards, application specific requirements, lifecycle analysis and economic factors

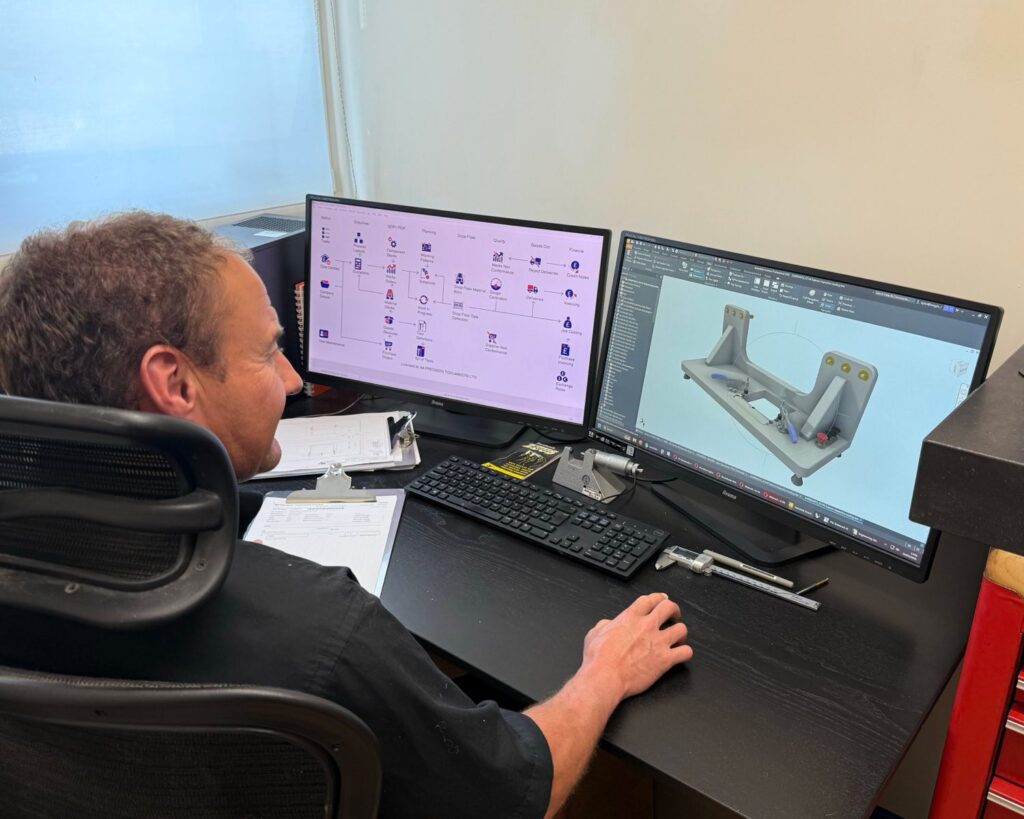

The choice of machine depends on the type of spring being tested and the specific parameters required for the test. Universal Testing Machines (UTMs) are versatile and widely used for compression and tension tests, while torsion testing machines are essential for testing torsion springs.

Fatigue testing machines are crucial for evaluating long-term durability, and environmental testing chambers help assess performance under various conditions. Specialized spring testers and advanced optical measurement systems can provide precise, automated testing capabilities.

The latest instruments from Starrett are classed as UTM’s and provide a stable platform for spring testing, also, as they are UTM’s they can be used for any of the standard applications that require force testing.

There are a choice of test stands, software options, load cells and fixture options, available capacities are 10,000, 30,000 and 50,000N on the dual column stands and 1000, 2500 and 5000N on the single column stands.

Starrett products are available in the UK from Optimax