Starrag Five Axis Machines Provide Diverse Growth Opportunities For Schaller

Estimated reading time 3 minutes

Speed, power and precision are qualities that are coveted by Justin and Maryann Schaller, both in terms of the family-owned Schaller Group and in their other shared passion of hydroplane racing. And the speed, power and precision of Starrag’s STC 800 X five-axis machining centres are playing a key role in both their business and their racing.

The brother and sister duo are executives of the Schaller Group (www.schallergroup.com), a third-generation Michigan (North America) based precision metal forming and assembly company that manufactures parts for the aerospace, military, automotive and medical industries.

For ten years, the siblings ran their own CNC machining company but in 2018 opted to bring their expertise back into the family stamping business. The company expanded one of its plants to 8,360 m2 and designated it to CNC machining. It is one of six specialised manufacturing plants operated by the group in the Detroit area.

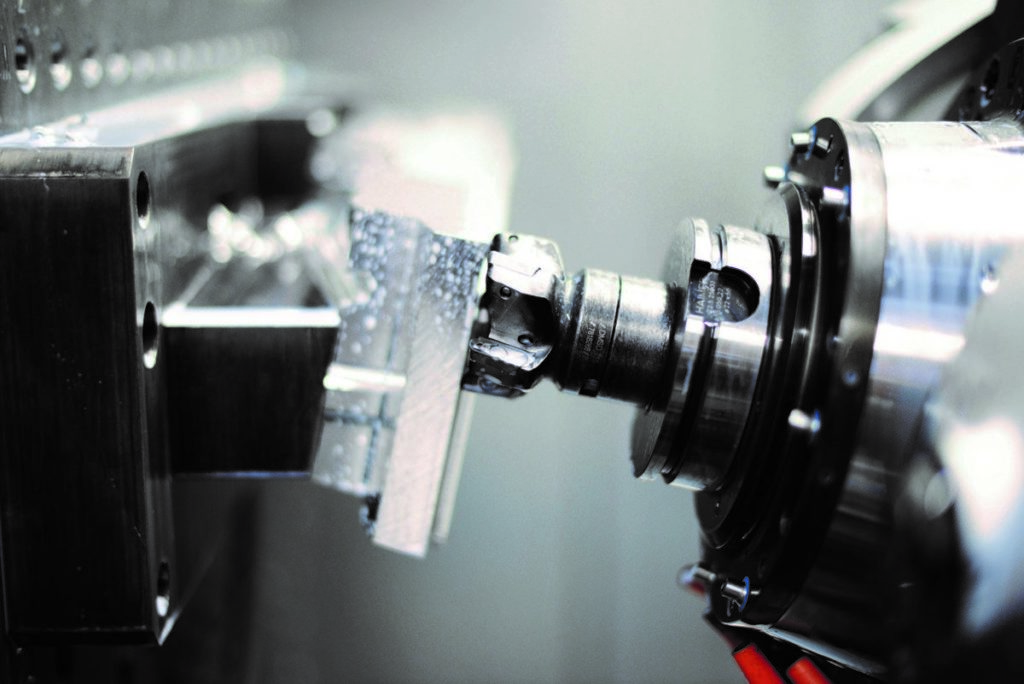

The Starrag STC 800 X was chosen not only because it is ideally suited to machining complex aluminium workpieces – as used by the aerospace industry, for example – but also because its precision capabilities, axis configuration and ability to five-axis mill with the use of a rotary table and a 30,00 revs/min, 120 kW tilting spindle will enable Schaller to expand into other industry sectors.

With an A axis range of -100/+60 degrees, no angle heads are necessary for machining complex parts. The rotary table allows economical machining by using a tombstone set-up or multiple parts and fixtures on the same table. Additionally, with two STCs integrated into a manufacturing system, Schaller has high levels of flexibility in production.

“These are the perfect machines for growth,” said Business Development specialist Maryann Schaller. One example is medical devices. In March 2020, parts were manufactured and donated for a prototype ventilator project in the hope of helping with the Covid crisis. And while that project did not take off as hoped, it showed Schaller another market where the precision and speed of the Starrag STC 800 X would be greatly beneficial.

The STC 800 X is ideal for machining 1,400 mm or smaller precision parts, which is what Schaller needs for the complex aerospace, defense and speciality industries it is expanding into. One such growth area is high-performance racing including watercraft such as hydroplanes and sleek offshore boats, as well as auto racing like stock, drag and rally. All rely on quality-built aluminium parts and, according to Maryann Schaller: “The STC 800 X is the perfect machine for work in these sectors as our racing experiences have introduced us to a network of potential customers. The speed of the Starrag machines along with the ability to utilise tombstones on a multi-pallet system will allow us to be competitive in the manufacture of engine blocks, heads, manifolds and other performance racing products.”

She concludes: “We started in the aerospace industry in the 1980s. It’s a great growth market, but we also know the importance of diversifying.” Schaller selected Starrag machines because they can be utilised in any industry that requires high precision, complex parts including racing vehicles, satellites or electrical vehicles. “Starrag’s capabilities allows Schaller to meet those diverse needs,” she says.