Steering Housing Production with Engis Single Pass Bore Finishing

Estimated reading time 3 minutes

For many hydraulic and automotive honing applications, Engis Superabrasive Single-Pass Bore Finishing offers the best of both worlds: high precision tolerances in a large scale production environment. Development over many years has led to significant advances in bore size, geometry and customisable surface finish – so much so that bore size control has now reached the limits of current air gauge capability..

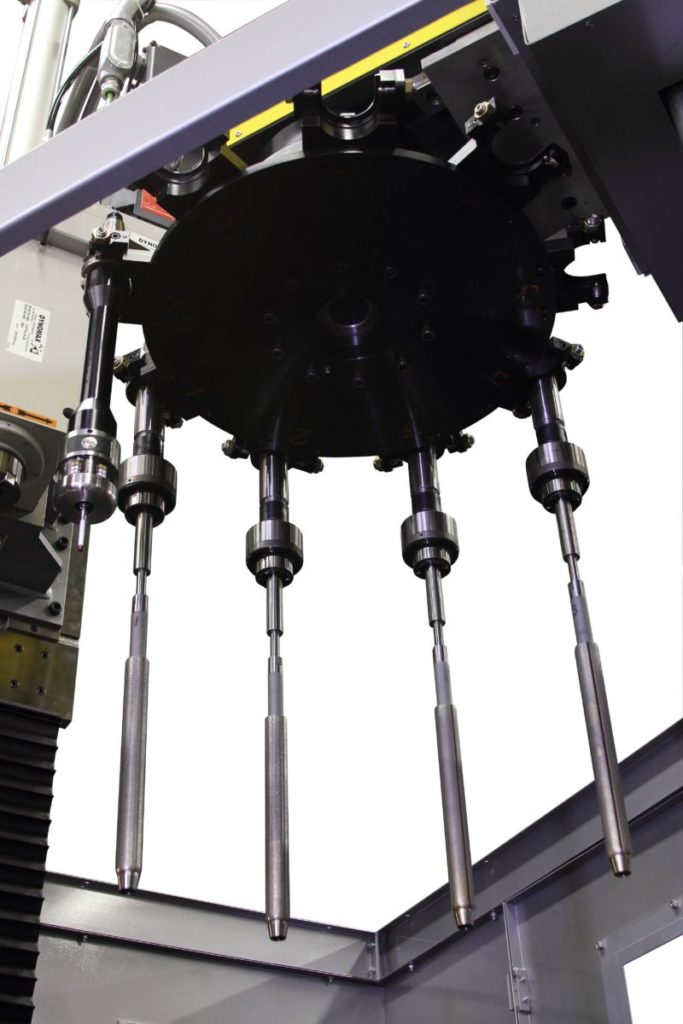

The Single Pass process uses a combination of superabrasive-plated tools, pre-set to exact dimensions, which are passed through the bore, rotating as they complete the honing operation. The number of tools required for any specific task depends on: the amount of material to be removed, the surface finish required and the specified final geometry: roundness, concentricity, bow and/or size.

It is this pre-set tool sizing, combined with the slower wear of the superabrasives, that enables the Single-Pass process to achieve the tightest bore size requirements with excellent statistical process control.

in order to achieve the best bore precision it is essential that the cutting tools follow the centerline of the existing bore with the least possible force and this is achieved by allowing either the component or the tooling to float. In situations where the part length is greater than three times the diameter of the bore, both axial and radial float are necessary.

In the case of this particular steering housing it was determined best to hold the part rigid and float the tooling, so spring-loaded holders provided the radial float for the tool assemblies, together with a special, free-pivoting union which was incorporated inside the mandrel of the tool. In this instance, up to 0.038 mm of ductile iron needed to be removed and, as the bore had limited clearance at the bottom, a semi-blind bore finishing tool design was needed.

The tooling progression consisted of a series of six tools ranging from 40/50 down to 200/230 mesh diamond. The process tolerance needed to be held within a total range of 0.7 um, including variation in bore shape and overall gauge accuracy and repeatability.

Using the Single Pass process, tool size can be maintained for relatively long periods of time, but it is important not only to monitor and control the size of the final finishing tool, but also of each tool in the progression. In addition, in order to achieve the required bore precision, each phase of the process must be correct, including the tooling, fixturing, floating mechanisms and gauge systems.

Today, many automotive sub-assemblies require increasingly tight clearances between mating components – the Single Pass Bore Finishing system helps make these requirements a reality.