Talon steps up a gear with Hipercar project working closely with WNT

Estimated reading time 5 minutes

Yeovil-Based Talon Engineering is renowned for its OEM aftermarket sprockets, hubs, wheels, clutch baskets and engine casings for the off-road motorcycle industry, but it is also growing into a major subcontract machining force. It machines parts for a wide range of industries, including agriculture, rail, aerospace, marine, and especially high performance automotive customers.

With preferred machining supplier status from near neighbour Ariel Motor Company, Talon has already worked on several high-profile projects, such as the Ariel Ace motorcycle. Now it is heavily involved with machining a range of parts as Ariel takes on the supercar market with its Ariel Hipercar a car described by Ariel as ‘an ultra-high performance, range extended, electric sports car’. Hipercar’s specification lives up to the description, with each wheel (in either two- or four-wheel drive) driven by an individual inboard motor via integral, single-speed, step-down gearboxes. With each motor developing 220 kW (295 bhp) and 450 Nm (332 ft lb) of torque the four-wheel drive variant has a power output of 880 kW (1,180 bhp), and similar astounding levels of torque torque, with 9,900 Nm (7301 ft lb) at the wheels in four-wheel drive trim. The result is that any mechanical components must be machined to high standards, but with Ariel’s own idiosyncrasies built in.

“Following the work we have been doing on earlier projects with Ariel including the Ace and a specialised wheel project, they have full confidence in our ability to deliver both the quality Ariel requires, and also to the time schedules that they are working to,” says Graham Alford, Talon Engineering’s Operations Director. “Because of the nature of development projects such as the Hipercar, design changes are frequent and being so close to Ariel geographically is a big help in that respect. Also playing an important role are our relationships with our machine and cutting tool suppliers.”

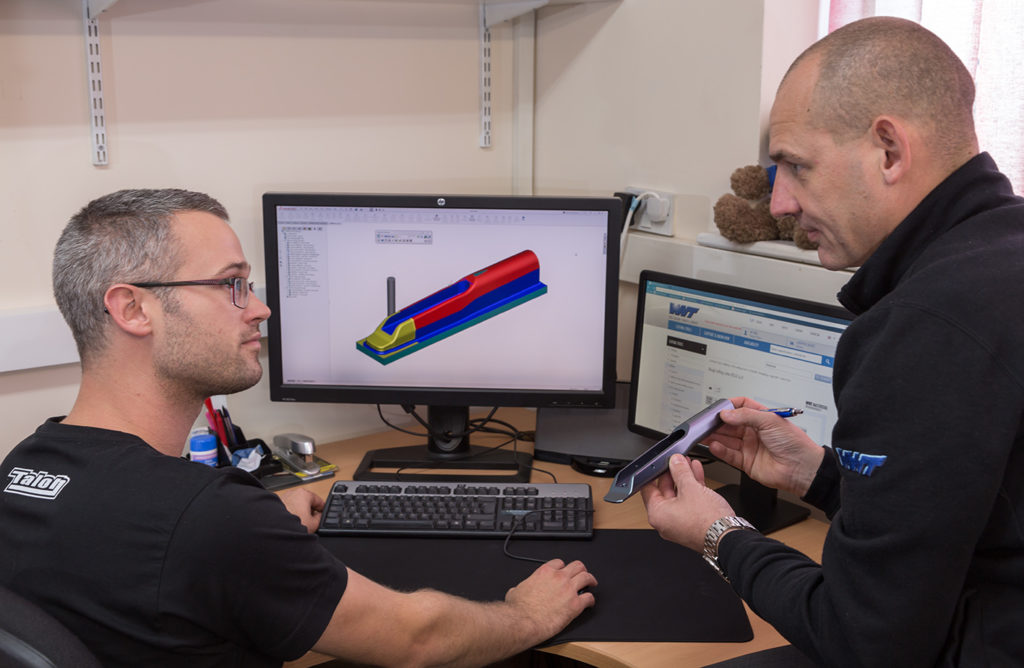

The fast pace of projects, such as Hipercar, means that Talon needs tools on the machine at short notice, working with WNT (UK) it has developed a standard list of tooling, including HPC cutters, Type W Alu line cutters, as well as making major use of WNT’s Centro P toolholding system. The majority of the cutting tools are held in WNT Vending machines, which are capable of holding up to three months of stock, ensuring availability around the clock. “We make this list of tooling available to our customers so that they can design parts around them, in the knowledge that they will always be there, ready to use. We wouldn’t be without the vendors now, they are integral to our business. Of course, when we need something not on our standard list, we know we can have it delivered by the following morning. This makes working on projects straightforward with the further benefit of the technical support we get from WNT’s Ian Tattersall and Vince Whitham, who are happy to stand by the machine and make things work.”

The components being machined by Talon for the Ariel Hipercar include wishbones, accelerator and brake pedals and assemblies, handbrake and chassis brackets, are quite challenging in the fact they require lots of 3D milling. Add to this Ariel’s requirement that feed marks have to be visible and, in some cases, corner radii machined to resemble welds, leading to some complex programming. Achieving this did pose challenges to Talon’s Process Engineers Sandy Bradley and Sam Chinn. “Leaving feed marks goes against all normal machining principles,” says Sandy Bradley. “But it is a requirement of Ariel, which started when we were machining the frame for their Ace motorcycle. The experience gained on that project made this one a little easier, but we still needed to calculate the correct step-overs, to in effect create a non-standard machined finish.” However, the level of detail and quality of the machining has been recognised, with Autocar magazine reporting that the suspension system components produced by Talon ‘comprise some of the best-looking billet-machined and anodised unequal length wishbones and uprights you’ll ever see’.

As part of this project, Talon has adopted new machining techniques with the support of WNT, with trochoidal milling being the way forward for much of the machining undertaken. “As this project moves forward into production trochoidal milling will bring further advantages as it reduces the stress and pressure on machine spindles,” says Sam Chinn. “Vince has worked with us on developing machining strategies and has acted as afresh pair of eyes, seeing opportunities that we may have missed, as well as standing by us on the duckboard while we were taking the first cuts. That way we quickly overcame any issues and it was an excellent example of knowledge transfer. This support we get from WNT allows us to step out of our machining comfort zone.”

In some respects the complex work that Talon is producing for Ariel is ideally suited to five-axis machining, but Talon has taken the decision to maximise its three-axis vertical machining centres, of which it has 12, overseen by just five operators. It also has fourth axis units available when required. This experience and ability is transforming the company’s sub-contract offering, which currently represents 25 per cent of company turnover. This share is growing rapidly through its policy of providing total management of machined parts, including material procurement, machining, assembly, Subcontract Plating/Painting & CMM Inspection, all of which is controlled by its ISO9001 & ISO18001 accreditations. Business growth is being driven by existing customers, as well as opportunities in other areas, such as nuclear, which Talon is currently part way through accreditation for.

“We have come a long way in just over 12 months since we worked on the Ariel Ace project, with what we learnt on that being transferred to the machining of Hipercar parts. The assistance that we have had in that time from WNT is invaluable and has allowed us to machine these parts efficiently and cost-effectively,” says Graham Alford.