The Missing Piece of Industry 4.0: Kitov.ai Automates Visual Inspection with CAD-Based AI.

Estimated reading time 2 minutes

Over the last decade, Industry 4.0 has smoothed the path for smart factories that support complex manufacturing methods using artificial intelligence, machine learning, automation, and real-time digital interconnectivity.

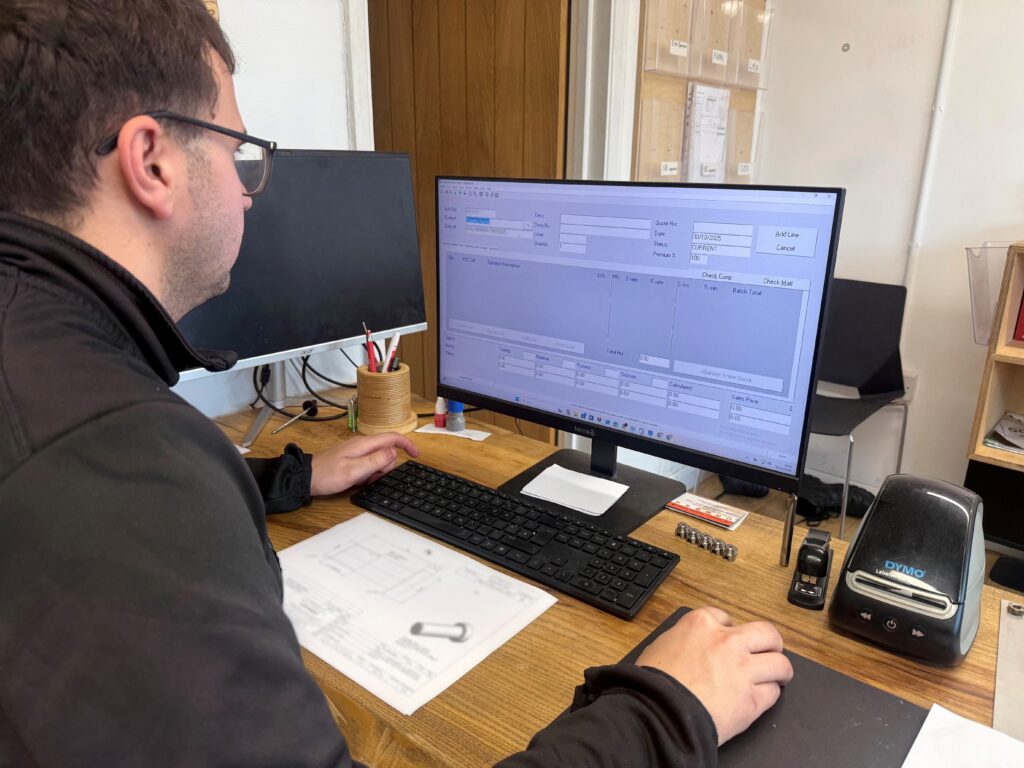

However, the visual inspection process remains a challenge for many smart factories, resulting in error-prone manual inspections for approximately a vast majority of manufactured products. Kitov.ai offers machine builders, system integrators, and planners automated CAD-based visual inspection planning based on artificial intelligence, representing a game-changer for industries that manufacture complex parts and products.

Kitov.ai’s hybrid vision systems combine the best of transitional machine vision techniques, including automated lighting control, with deep learning, 2D/3D imaging, and intelligent robotic planning, all in one platform. The newest Kitov Core-Plus offers a variety of sizes and in-line or batch configuration options, while the software makes it easy to program starting with CAD files or 3D scans, and then enhancing traditional 2D/3D machine vision solutions with the power of artificial intelligence/deep learning (AI/DL) defect classification and robot path programming. Kitov Core-Plus: Vision Guided Robot + Smart Planner + Review Station Kitov Core-Plus begins with a CAD file or, if a file is unavailable, a 3D digital twin automatically created by Kitov Core-Plus based on a 360-degree image scan. Operators use “plain English” semantic functions and simple boundary boxes to identify key inspection points. Kitov.ai software does the rest with the software platform enabling the building of automated inspection systems tailored precisely to industry needs. Using both AI and classical 3D Computer Vision, the software can be trained to find product defects such as:

- Cosmetic defects: scratches, dents, discoloration, etc.

- Mechanical defects: worn, untightened, or defective screws, defective labels, bent pins, etc.

The inspection can handle any 3D structures and geometries, making it ideal for complex part manufacture. The software learns as it goes, reducing inspection errors when a flaw detected earlier was marked as non-defective.

A broad range of industries and sectors—from electronics and automotive to defense, medical, and retail, among others—benefit from using Kitov’s software platform to build these automated inspection systems.

Bridging the gap in Industry 4.0 quality control, Kitov.ai provides foundational software that replaces error-prone manual inspection with automated, AI-powered, CAD-based visual inspection planning for complex manufactured products.

Visit Here to integrate Kitov.ai’s foundational software into ythe production process today.