WNT adds to process security with new collet range

Estimated reading time 3 minutes

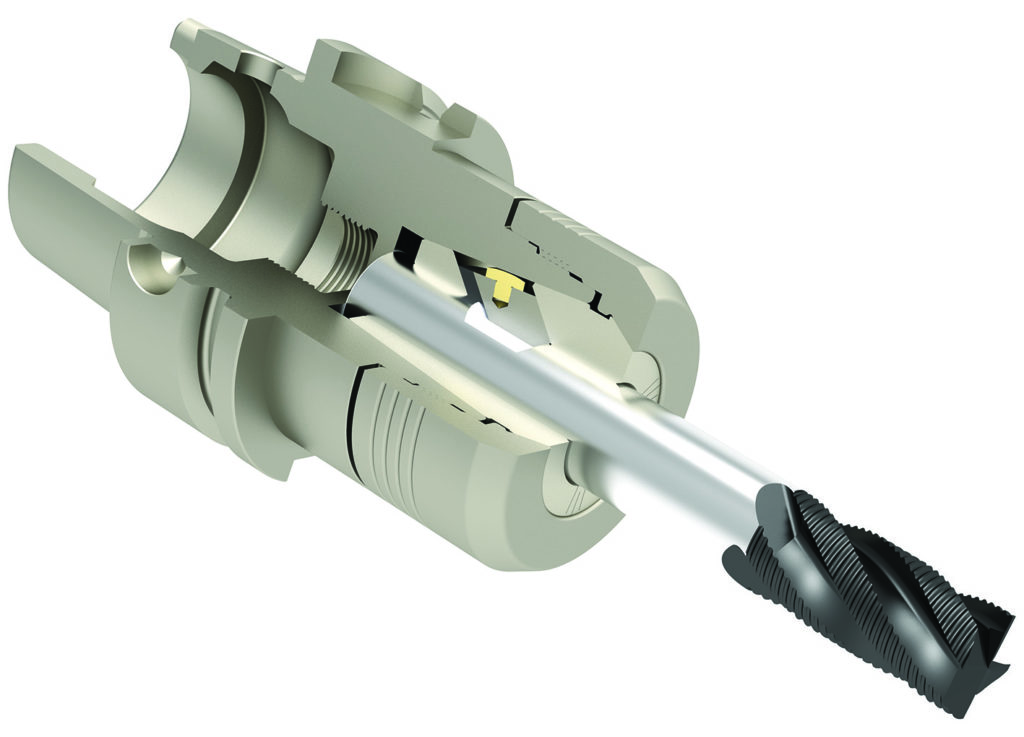

WNT has introduced a new range of precision collets that will enhance process security by eliminating any risk of cutters ‘pulling out’ under cutting conditions. The Centro│P.WD Wedge Collet, maximises the potential of Weldon shank-style cutters through its simple, yet extremely effective, mechanical clamping system.

Designed specifically to be used with WNT’s Centro-P chuck system the Centro│P.WD collets are based on the international DIN ISO 15488-B ER collet system, but feature an additional wedge-style locking system. When a Weldon shank tool is positioned in the collet the wedge is displaced, prior to locating on the Weldon flat. This is then secured in place when the collet is secured in the WNT Centro-P chuck, making it a purely mechanical system that requires no special tools, therefore it is both effective and easy to use. The new system is aimed at those customers wanting to employ high performance cutting strategies, or under high metal removal applications, where using conventional collets there is a significant risk that the cutter will pull out or creep under cutting conditions. The Centro│P.WD completely eliminates that risk, allowing users to maximise cutting data.

The new system is fully compatible with all of WNT’s Centro P collet chucks meaning that existing users only need to purchase the collet to take advantage of this additional process security. By combining the Centro│P.WD and Centro-P chucks users of Weldon style cutters can take advantage of the high rigidity and accuracy provided by Centro-P (<6 micron runout at 3x Dia) and the increased clamping forces, double that of conventional DIN chucks, that the Centro-P system generates. These performance gains are achieved through the taper angle of the chuck and collet being fine-tuned for maximum accuracy and the fact that unlike other systems the collet is completely seated within the taper of the chuck.

Collets are available in ER-32 designation in sizes of 12, 14, 16 and 18 mm and as ER-40 designation with a 20mm bore. And as with all products from WNT are available guaranteed for next day delivery, before noon, if ordered by 18:30 the previous day. “Innovative design doesn’t have to be complicated as the Centro│P.WD collets prove. This straightforward wedge system will eliminate a longstanding problem for those customers wanting to utilise Weldon shank cutters for high performance milling applications. The added process security and accuracy that the combination of Centro│P.WD and Centro-P bring in these applications will help to enhance productivity with minimal extra cost, thanks to the collet systems complete compatibility with existing Centro-P chucks, Says Tony Pennington, Managing Director, WNT (UK).

A demonstration of the new Centro│P.WD collets can be seen on the WNT website at https://tinyurl.com/npna78u This shows a WNT SCR HPC 16mm diameter cutter machining 42CRMo4 steel at 150m/min, 0.06mm/tooth feedrate, 12mm width of cut and 14mm depth of cut, using a conventional collet, then compared to a Centro│P.WD collet. With the conventional collet the cutter creeps by 2mm over a relatively short distance. With the Centro│P.WD the cutter creep is totally eliminated.

Issued on behalf of:

WNT (UK) Ltd

Sheffield Airport Business Park

Europa Link

Sheffield

S9 1XU

Tel: 0800 073 2 073

Fax: 0800 073 2 074

e-mail: tony.pennington@wnt.com

Website: www.wnt.com

Contact:

Mr Tony Pennington

Managing Director