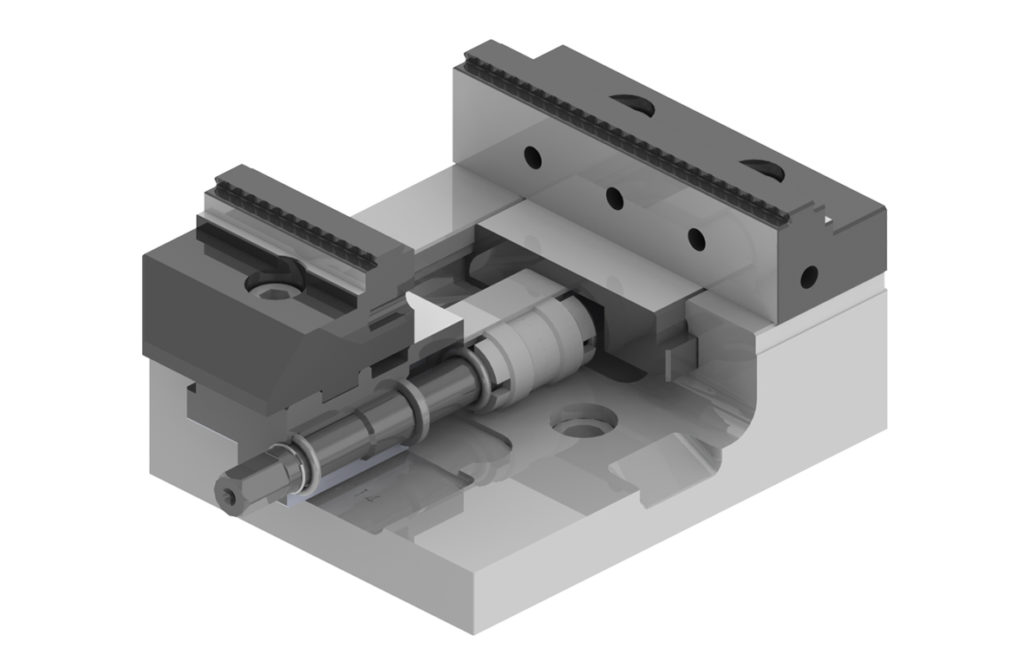

ZSG4 Vice for high precision and process security

Estimated reading time 3 minutes

The new ZSG4 centric vice system from WNT (UK) is a highly versatile workholding system that can be equipped with a multitude of jaw combinations, enabling a wide range of components to be gripped precisely and securely. The new system has several features that bring significant advantages to the production environment and has an added incentive of a 20 per cent discount on list price on all ZSG4 vices until 31st May 2015.

The six key features of the ZSG4 range are that it has a totally enclosed clamping system. This means that the vice operating system is protected from swarf ingress, making it easy to maintain and also very reliable in operation. ZSG4 also has high clamping forces and a large clamping range. Maximum gripping force is 35 kN and components up to 303mm in length can be held securely in its jaws. High Accuracy, is ensured through the vice design, which features precision matched slides resulting in repeatability of +/- 0.01mm. The use of a Ballscrew spindle totally eliminates backlash. The design of AZSG4 also allows for First and second operation machining, thanks to the ability to use gripped and smooth vice jaws in combination with the vice’s Compact design. The latter has created a maximum height from the machine table of 83 mm, which in turn makes it ideal for use on four and five axis machine applications by maximising available machine z-axis.

“With the ZSG4 customers now have a truly versatile and precise workholding system with enhanced process security due to its design features. This is backed by the quality ethos that runs throughout the WNT portfolio. With ZSG4 we have created a system that is universal in that it can be used as a stand-alone vice or can be employed in applications where pallet systems or zero point baseplates allow users to maximise the number of vices in use at one time, thereby reducing manufacturing costs,” says Tony Pennington, Managing Director, WNT (UK).

The versatility of the ZSG4 vice system is further highlighted by the wide choice of jaws that includes: reversible jaws; pendulum plate jaws; combi jaws; aluminium jaws; five axis jaws; smooth carbide coated jaws; and stepped jaws. In addition positioning of the vice on the machine table also comes with options such as the use of the machine table T-slots, grid plates or where required vice bodies feature slots running along their length, allowing multiple clamps to be applied. Alternatively for faster set or multiple set-ups the vice body connects directly to WNT’s MNG Zero point clamping system, or, on request vices can also be manufactured to suit specific zero point systems from other manufacturers.

A demonstration of the capabilities of ZSG4 vices can be arranged by contacting your local WNT technical sales engineer either directly or by calling 0800 073 2 073 the product brochure can also be downloaded from the WNT website www.wnt.com/uk/download.html