Fimark’s Role in the Aerospace Industry

Estimated reading time 3 minutes

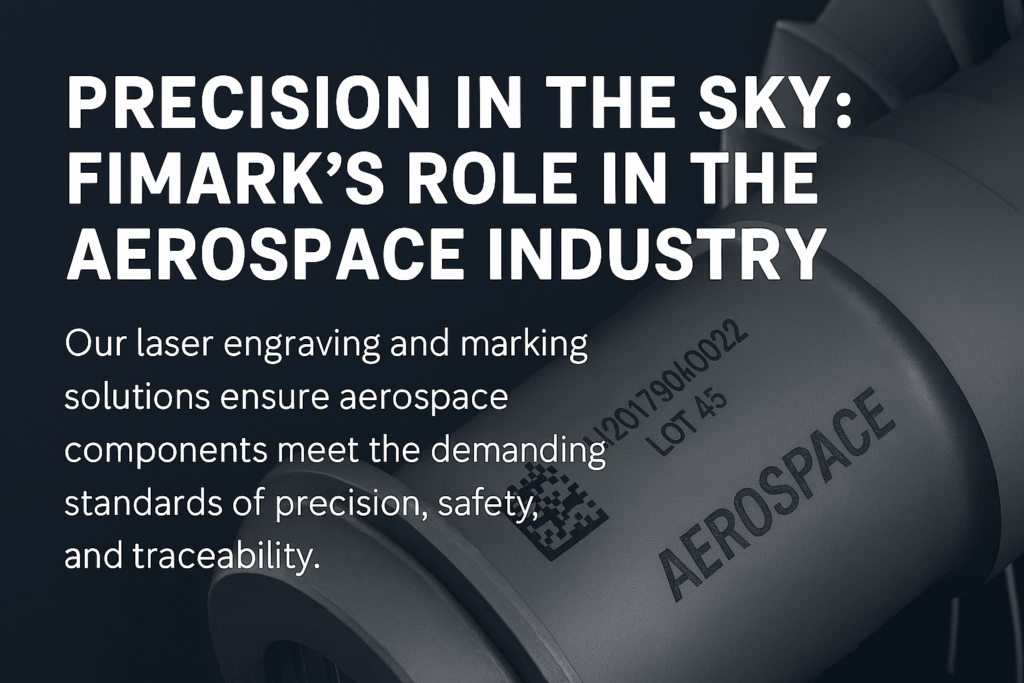

The aerospace industry is one of the most demanding sectors when it comes to safety and regulatory compliance. The need for high-quality manufacturing processes that ensure reliability and durability is paramount. At Fimark, we provide laser engraving and marking solutions that meet these rigorous standards. Our advanced laser technology plays a key role in ensuring aerospace components meet the exacting requirements needed for safety and performance.

Fimark’s Contribution to Aerospace:

Fimark works with aerospace manufacturers to offer precise engraving and marking on a wide range of critical components. Whether it’s turbine blades, aircraft frames, or avionics equipment, our laser technology ensures each part meets the highest standards of quality and traceability. With Fimark, aerospace manufacturers can count on durability, precision, and safety.

Marking for Traceability:

In aerospace manufacturing, traceability is essential for quality control, safety and compliance. Laser marking provides a permanent and legible marking system that allows each component to be traced back to its batch or manufacturing origin. Fimark’s laser systems make it possible to apply serial numbers, lot codes, barcodes and even QR codes- all crucial for maintaining the integrity of a complex supply chain. These markings not only improve efficiency but also ensure that parts are properly accounted for, reducing the risk of errors and defects.

How Laser Technology Enhances Aerospace Manufacturing:

Laser engraving ensures high accuracy and the ability to mark intricate designs on complex geometries, even on difficult-to-reach areas. Unlike traditional methods such as mechanical engraving or chemical etching, laser technology offers speed, accuracy and superior repeatability.

Compliance with Industry Standards:

Fimark ensures that our laser engraving and marking solutions comply with stringent aerospace industry certifications. These standards ensure our services meet the highest levels of quality and safety which is essential in the aerospace sector. By using Fimark’s services, aerospace manufacturers can ensure their products are compliant with the regulatory requirements that govern the industry, which in turn guarantees the reliability of their components.

Aerospace Case Study:

We regularly laser engrave unique identification codes onto critical engine components for a leading aerospace manufacturer. These markings ensure easy traceability of each part throughout its lifecycle. The accurate and permanent nature of the laser markings helps the client meet both regulatory requirements and their internal quality control standards.

Our technology ensures that aerospace components are not only compliant with the highest safety standards but are also precise, durable and traceable. Whether you are looking to mark critical parts for traceability or add intricate engravings to enhance product quality, Fimark is here to support your needs.

Get in touch with Fimark today to discuss how we can help you improve the quality, safety and traceability of your aerospace components.

Visit our website www.fimark.co.uk or follow us on LinkedIn for more information about our work in aerospace and other industries.