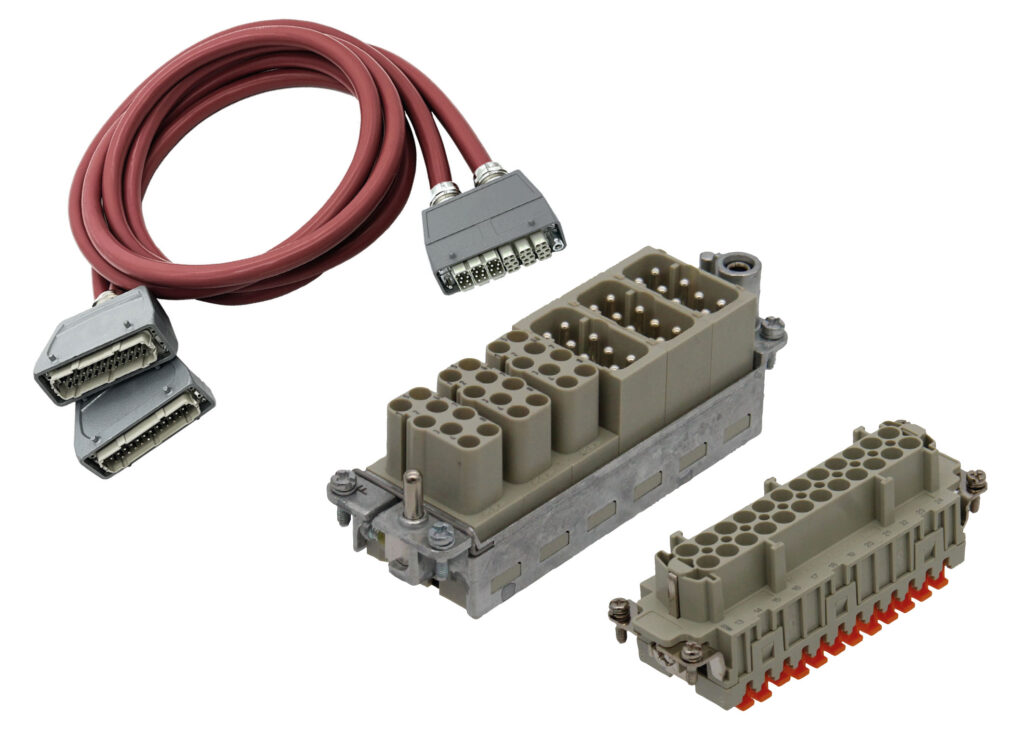

More performance in less space – HASCO plug insert for 12 control zones

Estimated reading time 2 minutes

Anyone involved in mouldmaking who has to work in a limited space knows that every millimetre counts.

With the HASCO plug insert H12294/… for 12 control zones, the available space can be optimally utilised – without any compromises as regards the performance. Despite the high connection density, the maximum load capacity of 16A is completely retained. Large, complicated connection boxes are replaced by a compact, convenient solution. The mounted housing corresponds to the previous 6-zone variants.

A major advantage is that only half the bulkhead mounted housing is needed. Especially for small, compact moulds or also for large multi-cavity injection moulding tools, in which it commonly happens that the connection boxes stick out from the mould and cause problems during assembly, this plug insert provides the perfect solution.

Reliable connection through the crimp technology

The cables are fixed by means of a crimp connection. Whereas the wires are compressed permanently and reliably in the pins, they can be removed from the plug at all times with the necessary tool and thus be rewired. The crimp technology thus offers a fast variation of the wiring, which guarantees safety, reliability and long life.

All from a single source

To go with the plug insert, HASCO Hot Runner supplies the optimally coordinated cables – if required also as a connecting cable with compact pin assignment on the one side and the usual wiring on the other. This means that the existing control technology can still be used without problem – without modifications and without compromises.

Should a different wiring standard be desired, this can simply be entered in when the order is placed. HASCO Hot Runner produces this connecting cable – like the entire cable portfolio – specially customised for the customer.

With this innovative product combination, HASCO Hot Runner offers a well-conceived, space-saving solution that makes day-to-day production more efficient and less expensive thanks to the approx. 75 % less wiring time – and that with the customary high HASCO quality.