MRP vs ERP: Which Software Is Best for Subcontract Precision Engineers?

Estimated reading time 3 minutes

When it comes to managing a successful subcontract manufacturing business, choosing the right software can make all the difference. Two of the most commonly used solutions are MRP software (Material Requirements Planning) and ERP software (Enterprise Resource Planning). While both offer valuable tools for manufacturers, understanding their differences is key to selecting the best fit for your business. A third option is production control software, which we’ll come to later.

What Is MRP Software?

MRP software is designed to help manufacturers manage material planning, inventory control and production scheduling. It ensures that the right materials are available at the right time to meet production demands.

Key Features of MRP Software:

- Inventory management: Tracks raw materials, work in progress and finished goods

- Bill Of Materials (BOM): Ensures accurate definition and allocation of component and material BOM items

- Production planning: Helps schedule jobs efficiently

- Purchasing control: Aids purchasing to avoid shortages or excess stock

MRP software provides precise control over materials and scheduling to prevent production delays and inefficiencies.

What Is ERP Software?

ERP software is a broader system that integrates multiple business functions, including MRP, finance, customer management and human resources.

ERP solutions provide a centralised platform for managing an entire manufacturing operation.

Key Features of ERP Software:

- Comprehensive control: Includes MRP functionality along with finance, sales and HR management

- Real-time data visibility: Provides insights across departments for better decision-making

- Order management: Tracks customer orders from quotation to delivery

- Compliance and traceability: Supports ISO standards and regulatory requirements

An ERP system offers a more holistic approach for manufacturers, ensuring that all business processes are aligned for maximum efficiency.

MRP vs ERP: Which One Is Best for Subcontract Manufacturers?

The choice between MRP and ERP software depends on the complexity of your business.

| Factor | MRP Software | ERP Software |

| Business Size | Small to Medium | Medium to Large |

| Focus | Material & Production Planning | Comprehensive Business Management |

| Integration | Standalone | Multi-department Integration |

| Scalability | Limited | Highly Scalable |

| Cost | Lower | Higher |

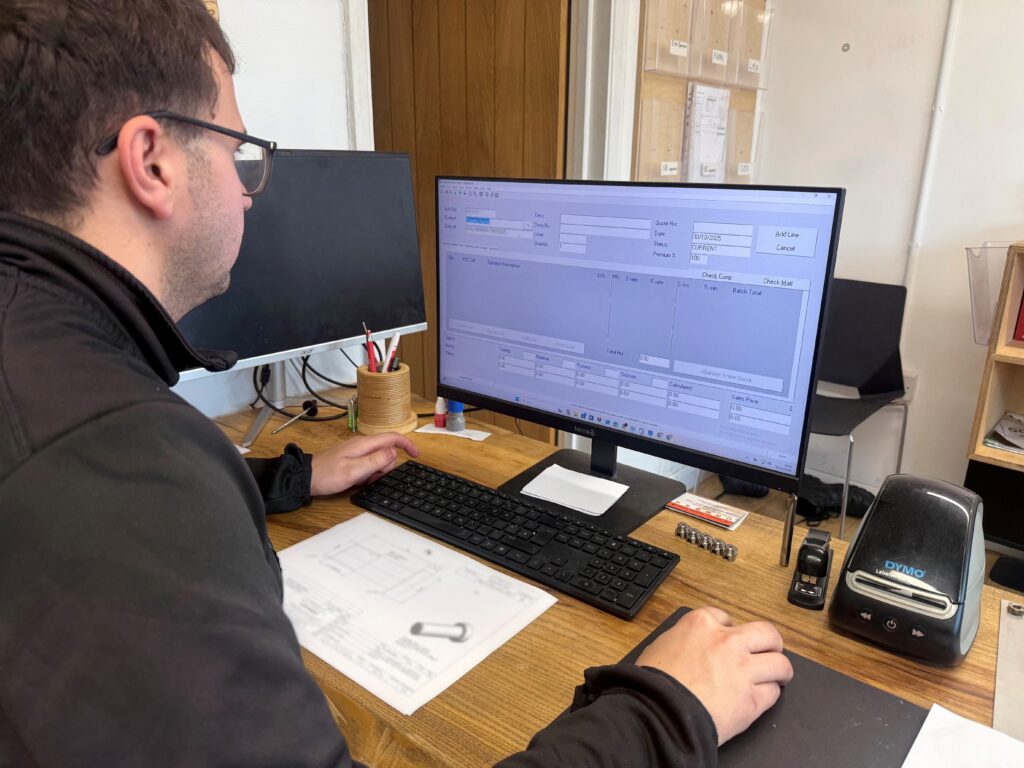

The Third Option: Why PSL Datatrack Production Control Software Is the Ideal Solution

For subcontract precision engineers looking for flexibility and traceability, PSL Datatrack offers a modular production control software system that provides many of the benefits of both MRP and ERP software. It allows businesses to start with core MRP functions and expand into a more comprehensive solution as they grow.

With PSL Datatrack, you can:

- Streamline the quoting process to generate estimates quickly and efficiently

- Streamline material planning to reduce waste and improve efficiency

- Improve scheduling and job tracking for better management and efficiency

- Enhance traceability for ISO compliance and quality control

Conclusion

Choosing between MRP and ERP software depends on your subcontract manufacturing needs. If you require efficient material planning, MRP may be enough. However, if you need a complete business management solution, ERP covers non-manufacturing areas such as integrated accounts & HR.

PSL Datatrack offers a scalable, modular approach that grows with your business, ensuring you have the right tools at every stage of your journey.

Numerous customer testimonial videos are available, highlighting how PSL Datatrack has helped subcontractors to streamline their operations. Watch them here: www.psldatatrack.com/videos

For a no-obligation discussion on how PSL Datatrack can optimise your manufacturing processes, contact us today.