New start-up moves rapidly into 5-axis work

Estimated reading time 3 minutes

Rapid CNC Services Ltd, a new subcontracting machine shop based in Stockton-on-Tees, is targeting advanced 5-axis machining projects with the support of Yamazaki Mazak.

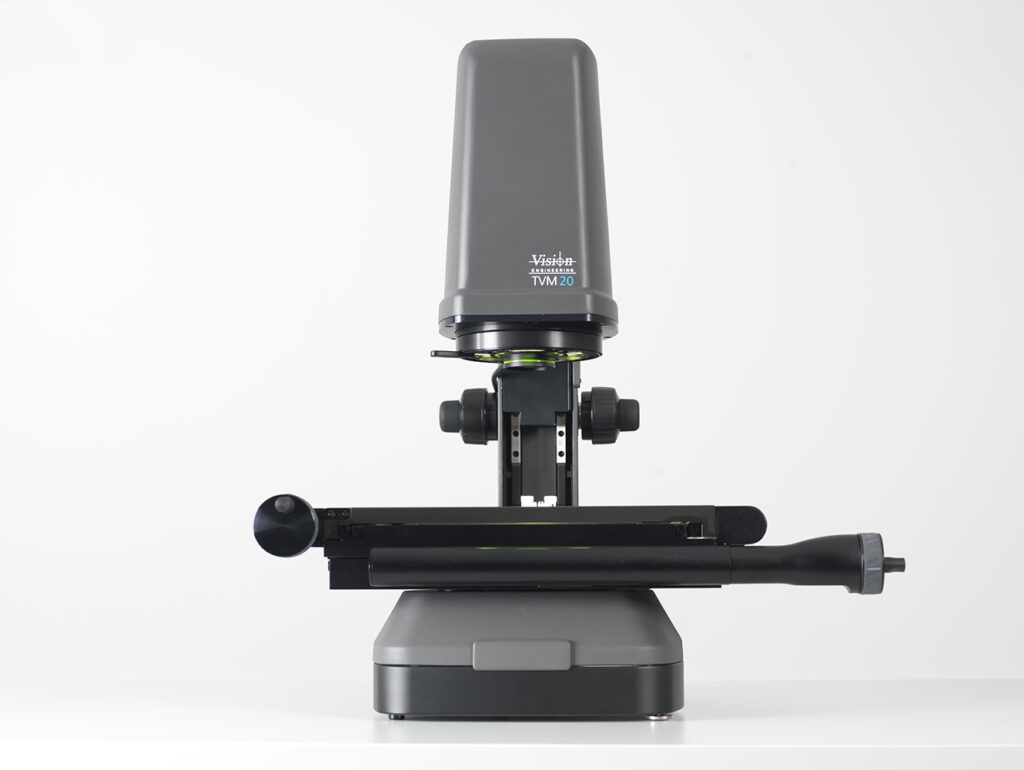

Founded by Rafal Grzenkowicz and Krzysztof Czerniawski, who collectively bring over 50 years of experience in CNC machining—including milling, turning, programming, and inspection—Rapid CNC is well-positioned to deliver cutting-edge manufacturing solutions.

The company operates from a modern facility on the Primrose Hill Industrial Estate in Stockton-on-Tees, where it has recently installed its first machine: a Mazak CV5-500 simultaneous 5-axis machining centre.

“We’re an ambitious start-up with big plans to offer fast and efficient subcontract manufacturing services using the best technology available,” says Rafal. “Our focus is on challenging projects that demand creativity and advanced programming skills.”

The decision to launch Rapid CNC was inspired by years of experience working with CNC machines. “Krzysztof and I have both long considered starting our own business,” Rafal explains. “We firmly believe that success will come from running an efficient, competitive business underpinned by state-of-the-art 5-axis technology.”

Initially, when selecting a machine, the team explored a range of suppliers. “However, we now know that choosing to partner with Mazak was an excellent strategic decision,” Rafal continues. “Mazak is a highly respected manufacturer of CNC machines, and our collaboration has been exceptional. The entire team, including Mark Ireland, our dedicated sales representative, has been incredibly supportive and reliable. Their service team is available within 24 hours, providing us with the confidence that any issues will be swiftly addressed, minimising potential downtime and ensuring uninterrupted operations.

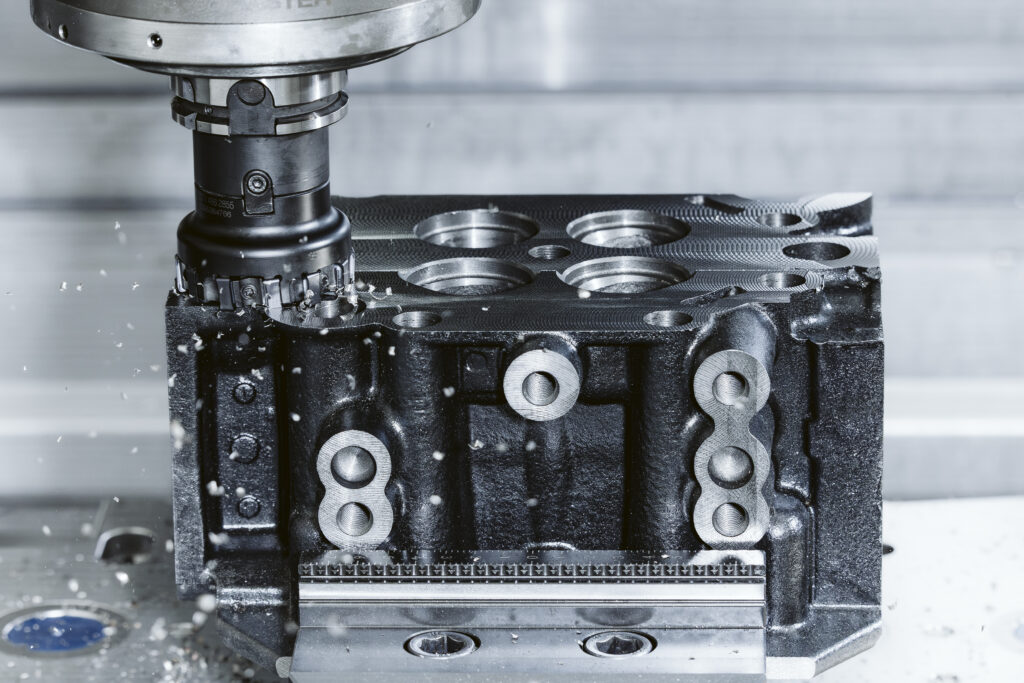

The strategic move to 5-axis machining was driven by their past experiences with lower-specification machines. “For the complex, high-value projects we’re aiming to attract, 3-axis machines require too many operations and consume too much time,” Rafal explains.

“Simultaneous 5-axis machining can reduce machining times by up to 40% and allows us to take on a wider range of jobs, many of which can be completed in a single setup. We’ve already found that the machine’s Smooth Technology CNC is incredibly efficient for high-speed milling.”

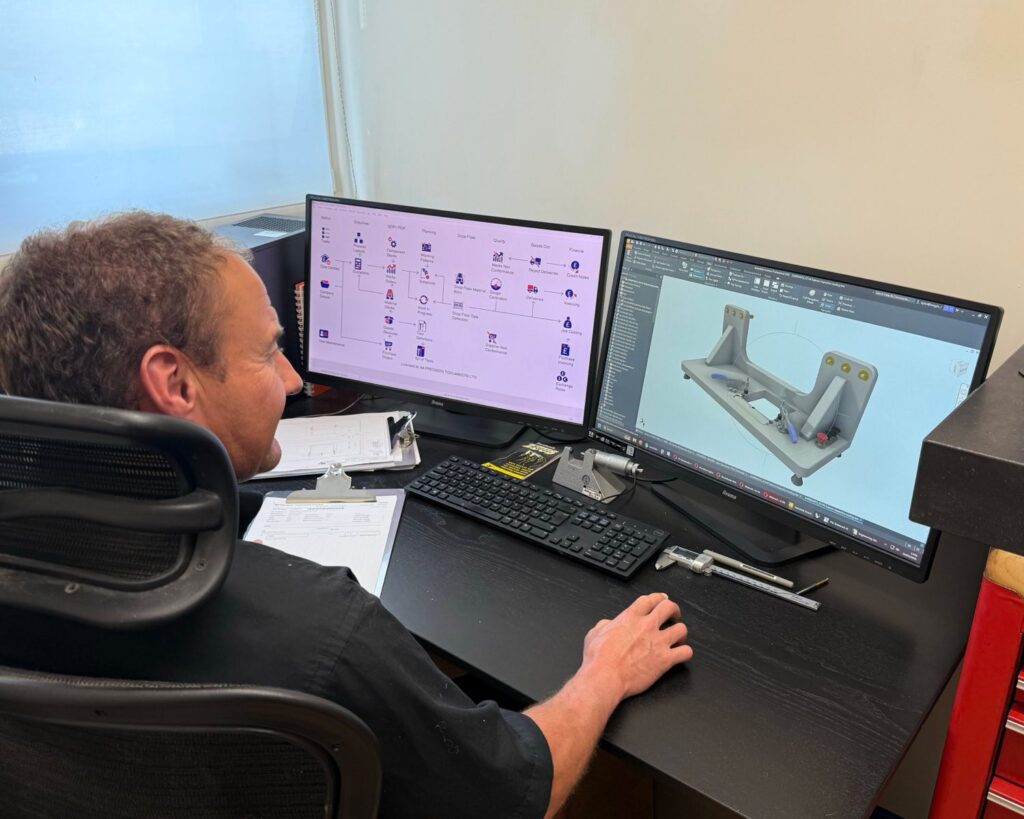

The Mazak CV5-500, designed and manufactured in the UK, is a simultaneous 5-axis machine ideal for subcontract manufacturers transitioning to more complex machining work. Rapid CNC’s model, equipped with Renishaw probing, was delivered just four weeks after the order and integrated seamlessly with their Fusion 360 design and 3D modelling software.

“We considered other 5-axis options, including 3+2 machines, but the CV5-500 stood out,” Rafal adds. “We saw the machine being manufactured in the Worcester facility and experienced the company’s excellent support through the buying process. In addition, the finance and training packages, as well as three days of on-site installation and commissioning support, were invaluable.”