Constell Engineers Ltd

Constell Engineers Ltd, situated 5 minutes’ drive from Junction 21 of the M62 (adjacent to the new Kingsway Business Park) has been established since 1960 and is proud to have been a member of the GTMA for over 40 years.

We are a toolroom specialising in the project management, tooling, design and production of all types of moulds and dies (prototype to multi-cavity) for TPE, Plastics, Rubber and Die-cast components for all industries including automotive, white goods, electronics, medical and leisure

Through close involvement with our customers, starting at the planning stage through design, production, and delivery, we offer engineering solutions to meet competitive budgets and deadlines. We offer weekly customer reports and timing plans on all new tooling so that customers can be confident that their project is on schedule.

Our in-house design service, utilising the latest version of Solid Works, Siemens NX6 and state-of-the-art computer equipment, is operated by experienced design staff, who are trained to work closely with the customer, producing a tool design that meets our customers’ needs. Our Design Reviews offer customers the opportunity to view, in full 3D, the completed assembly before production commences.

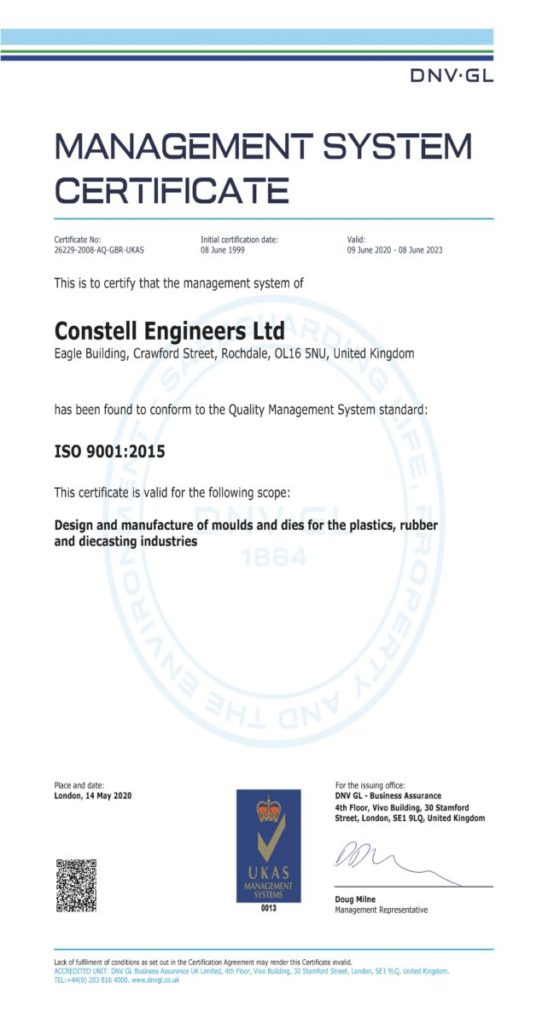

We have 19 years of accreditation to BS EN ISO 9001 and were accredited the new 2015 standard in June 2017. Our toolroom facility includes 3D CNC milling, 4 axis CNC spark eroding and CNC wire erosion all linked directly to our CAD/CAM systems. Conventional milling, turning, grinding and polishing equipment are also available.

Here at Constell we have developed a way of using Microsoft Project that enables us to ensure that all work we undertake is carefully planned and that all resources available to the company are efficiently scheduled to achieve the shortest possible lead time.

We also undertake modification, repair and refurbishment of all existing tooling, thus providing a complete after-sales service.

Constell operate a same-day quoting service on receipt of component data, or a sample component.

CNC VERTICAL MACHINING CENTRES

- 1 off Spinner VC1200-HS Vertical Machining Centre with Siemens 840D-Solution Line

- 3 off XYZ 1060 HS Vertical Machining Centre with Siemens 840D Shopmill

- 1 off Deckel Maho DMG 63V with Siemens 810D Control

- 1 off Electrodemaster Maxsee H56S

ELECTRICAL DISCHARGE MACHINES

- 1 off ONA Techno HS400 Spark Eroder

- 1 off ONA Techno H400 Spark Eroder

- 1 off ONA DB 300 Spark Eroder

- 1 off ONA AE300 Wire Cut Machine

- 1 off EDM Hole Start Machine

OTHER CNC MACHINES

- 1 off Mitutoyo BH504 Co-ordinate Measuring Machine<l/i>

- 1 off Dugard Lunan 1955 Multifunction CNC Lathe

- 1 off Harrison Alpha + CNC Lathe

CAD/CAM

- 2 off Solidworks Professional

- 1 off Siemens NX

- 2 off Mastercam Mill X8

- 1 off Cimatron EDM Electrode

- 1 off OneCNC XR6 Lathe Express

- 1 off Esprit

MANUAL PLANT/MACHINES/EQUIPMENT

- 1 off Milutensil BV25P Tool Try Out Press

- 1 off XYZ 2000 Manual Turret Mill

- 1 off Bridgeport Manual Turret Mill

- 1 off Thomson Precision Hydraulic Surface Grinder

- 1 off Jones & Shipman 540 Precision Hydraulic Surface Grinder

- 1 off Kitchen-Walker 50/1600 Radial Arm Drill

- 1 off Ajax Cleveland Universal MM

- 2 off Ultrasonic Polishing Equipment

Contact Constell Engineers Ltd

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU