Eclipse Magnetics

We manufacture high-quality magnets, supporting various industries with advanced magnetic technology and equipment. We produce Magnetic Filtration systems for CNC or EDM machine fluids, Magnetic Chucks for precision steel machining and Magnetic Lifting solutions for the safe movement of steel. In addition, we have a arrangement of magnetic workshop tools such as DTI bases, sweepers, pick-up tools and swarf wands.

Applying Magnetic Technology to Solve Industry Problems

Our business is making a difference to your business by applying magnetic technology. With our unrivalled magnetic products portfolio and wealth of expertise, we can drive a competitive edge into your business by reducing costs, increasing operational efficiency, improving safety or environmental benefits for a variety of engineering applications.

Our range includes the following:-

Fine Particle Performance Magnetic Filters

Our magnetic filters are the most effective way of removing problem ferrous particles from industrial fluids such as machine tool coolants, cutting oils, lubricants, grinding fluids and industrial wash solutions.

Magnetic filters reduce the need for disposable barrier filters, reducing costs, waste generation, and downtime. They also increase fluid life and can improve product quality.

These filters are widely used in a range of precision machining applications such as precision grinding, honing, lapping, drilling, cutting, steel rolling, EDM and wash stations.

Workholding – Magnetic Chucks

Since inventing the world’s first permanent magnetic chuck in 1934 we have remained at the forefront of workholding systems. We offer a range of permanent magnetic chucks and electro-permanent magnetic chucks for clamping or holding in grinding, milling and cutting applications. Applying magnetics gives faster feed and set up rates, greater accuracy and reduced vibration.

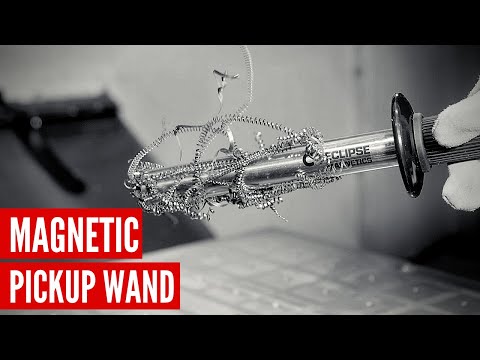

Workshop Tools

Our range of magnetic tools overcome everyday workshop challenges. Applying magnetics, we offer an extensive range of magnets and magnetic aids which provides an opportunity to save time and money or improve safety in your day-to-day business.

The range includes a unique range of magnets, pot magnets, electromagnets, retrieval tools, pick-up tools, magnetic welding aids, magnetic bases and magnets for display and retail applications—each product option designed to make your working day easier and more profitable.

Whether it’s a stock magnet for an OEM project, magnetic welding clamps, magnetic chucks, magnetic bases, simple magnetic workshop tools such as tool racks or swarf wands, magnetic signage or simple pot magnets we can offer a quality option at affordable prices.

Magnetic Solutions for Design Projects

With over 100 years of magnetic expertise, we are one of the world’s leading magnet suppliers. We can help you turn your ideas into profit by applying magnetism to maximise performance efficiency or reduce costs. We work closely with our clients to produce value-adding magnetic solutions with either an existing off-the-shelf magnet, such as a ring, bar, disc or magnetic block or designing a bespoke magnet or a full magnetic assembly. With a wealth of magnetic resources and expertise, we can help you fulfil your next-generation design projects.

Magnetic Lifting & Handling Systems

Our magnetic lifting & handling systems are based on fail-safe magnetic technology which delivers lifting speed, accuracy and efficiency whilst ensuring maximum safety. Ideal for applications ranging from light pick and place or robotics to heavy steel stock movement, applying magnetics’ to lifting and handling gives the safest, most efficient method of moving ferrous loads.

Eclipse also run a suite of webinars, please click on the title of interest for full details:

A Beginners Guide to Magnetism & Magnet Materials