Fimark Ltd

Processes include technical spray painting, laser etching and engraving and 3D laser texturing.

Fimark provides advanced coatings and luxury and functional finishes for the automotive, aerospace, medical and defence industries.

Processes include technical spray painting, laser etching and engraving and 3D laser texturing.

TECHNICAL SPRAY PAINTING AND LASER ETCHING

Our technical spray painting and laser etching capabilities are used for the manufacture of backlit buttons and fascias for dashboards and driver controls. Our components can be found on a wide range of vehicles including Aston Martin,Audi, Bentley, Peugeot and Renault.

ENGRAVING AND MARKING SERVICES

Our engraving and marking services are used for various reasons. Many manufactured and imported components need branding or marking in the form of logos, serial numbers, barcodes, product codes or user instructions and warnings. Using a laser to mark this information gives a permanent, aesthetic and non-damaging solution. Parts can be directly marked or engraved without the need for labels.

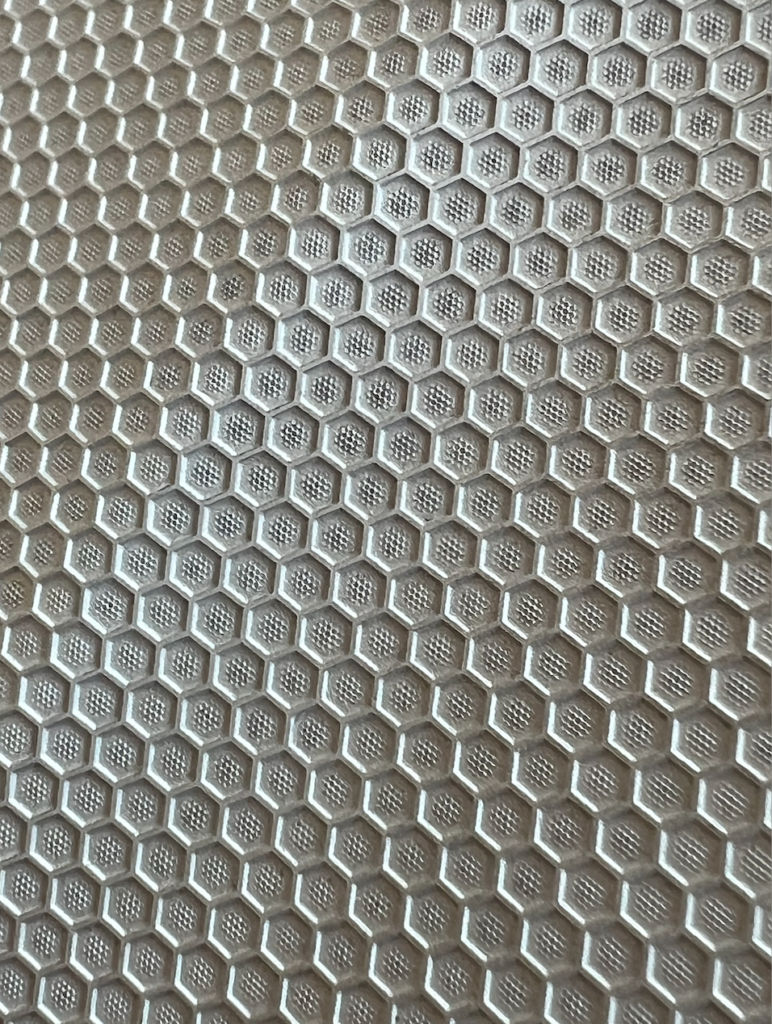

LASER SURFACE TEXTURING

3D laser texturing has various uses in industry including the texturing of moulds or directly onto components for improved aesthetics and light refraction. This technology allows engraving on complex geometries of the finest textures on a wide array of materials (steel, aluminium, carbide, brass, graphite, copper, ceramics) and competes with the finest hand engraving. Laser Surface Texturing can be used for product differentiation, decoration and for adding value to already finished components such as watches and jewellery.

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU