Hybrid Manufacturing Technologies

Pioneers and the world’s leading authority on hybrid manufacturing

World-Class Additive Manufacturing Solutions for Your Business

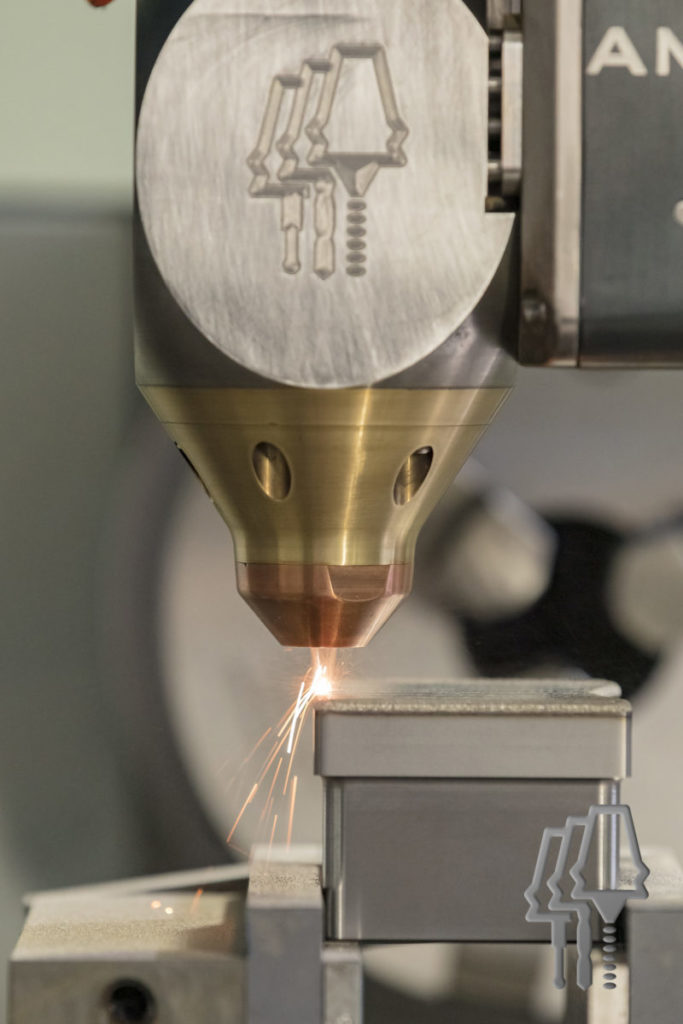

At Hybrid Manufacturing Technologies Global, we’re reshaping manufacturing by combining industrial 3D printing, known as additive manufacturing (or AM), with traditional machining in one seamless system. Our patented AMBIT™ tool-changeable laser cladding heads make this possible, offering a unique solution that enhances both processes. This hybrid approach allows for advanced— capabilities you won’t find in standalone systems.

Our Product Offerings are Vast, we Offer:

- Laser Drilling

- Laser Metal Deposition (LMD) or Directed Energy Deposition (DED)

- Bespoke Hybrid Manufacturing Systems

- Surface Coatings

- In Process Finishing

- Repair and Remanufacture

- Inspection

- Material Extrusion

- Process Development

Since the early 1990s, research has highlighted the potential of combining additive techniques with milling. Yet, despite this promise and a few successes, there were no commercial solutions for mainstream machine tools to add metal — until we stepped in.

Focused on creating a more practical solution, we developed a suite of deposition heads that could be added to CNC machines, robots and gantries without changing their structure. By 2013, Hybrid Manufacturing Technologies Global was turning this innovation into a commercial reality. For more than twelve years we have continued to provide stellar service and advanced manufacturing solutions to diverse areas of industry. We are committed to continuous growth and have expanded our global reach, to not only include our manufacturing facility in the United Kingdom, but also to our service locations in The United States and The Netherlands.

At our core, we’re all about unlocking new possibilities in manufacturing. Solving industry challenges and creating solutions to help teams improve manufacturing lead times and production challenges with additive technology — without sacrificing performance. Whether you want to reinvent your existing machine tools or design a custom solution, we’re here to help you elevate your manufacturing potential!

Contact Hybrid Manufacturing Technologies

"*" indicates required fields