Pemberton Engineering Ltd

A wealth of experience in all aspects of press tool design and manufacture

Founded in 1984 by Christopher Pemberton, Pemberton Engineering has been manufacturing press tools, jigs and fixtures for over 35 years. The company started by manufacturing small press tools for the lock industry, which was still flourishing in the Black Country. As this industry began to decline in the 1990’s Pemberton began manufacturing small tools for the automotive sector.

The company soon found itself manufacturing larger tools for lorry and tractor components, and over the past 10 years Pemberton has been manufacturing tools for Tier One automotive suppliers. The size and complexity of the tooling it supplies today has grown far beyond its early days with more complex progression tooling becoming the new norm.

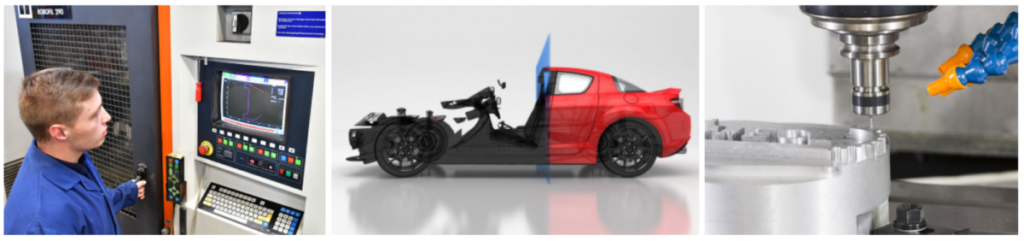

CNC Machinery

The company has invested heavily over the past decade in new CNC Machinery, Wire Eroders and CMM (coordinate measuring machine) equipment. With the next generation of the Pemberton family taking over the running of the company, the future is bright and full of new opportunities. In 2018 the company purchased its neighbouring industrial unit to double its production facility and has undertaken the process of gaining AS9100 accreditation for the aerospace industry.

Turnkey Manufacturing Service

Pemberton Engineering offers a complete turnkey service for the manufacture of press tools, jigs and fixtures. With over 35 years’ experience we provide high quality tooling at competitive prices. Our highly skilled workforce and state of the art CNC machinery makes Pemberton Engineering the supplier of choice for many OEMs from a diverse range of industry sectors.

Automotive Tools

Pemberton Engineering has been manufacturing press tools, jigs and fixtures for over 35 years. Producing tools for a variety of industries, in recent years this has centred around the strong automotive growth sector. The company has a wealth of experience and has a policy of training apprentices to be part of our skilled workforce of the future. We are constantly re-investing in machinery, people and facilities in order to maintain the high quality of manufactured tools and services we offer our customers.

Lead times and a prompt repair service are high priorities for us, as our customers demand that products arrive on time and can be assured of an attentive and prompt service back-up. Our vast experience allows us to highlight possible problems when tooling is designed, speeding up the manufacturing process and mitigating for flawed designs. We have a wealth of experience in all aspects of press tool design and manufacture, working with a multitude of materials from brass and aluminium through to much stronger tensile properties of 550MC and similar.

Contact Pemberton Engineering Ltd

"*" indicates required fields