Waveney Precision Ltd

Waveney Precision Ltd is a specialist precision engineering company that combines comprehensive plant and expertise to provide both EDM wire-cutting, die-sinking and CNC machining capabilities. As a result of investment, their premises is fully equipped with the latest CNC equipment.

Waveney Precision Ltd is a specialist precision engineering company that combines comprehensive plant and expertise to provide both EDM wire-cutting, die-sinking and CNC machining capabilities.

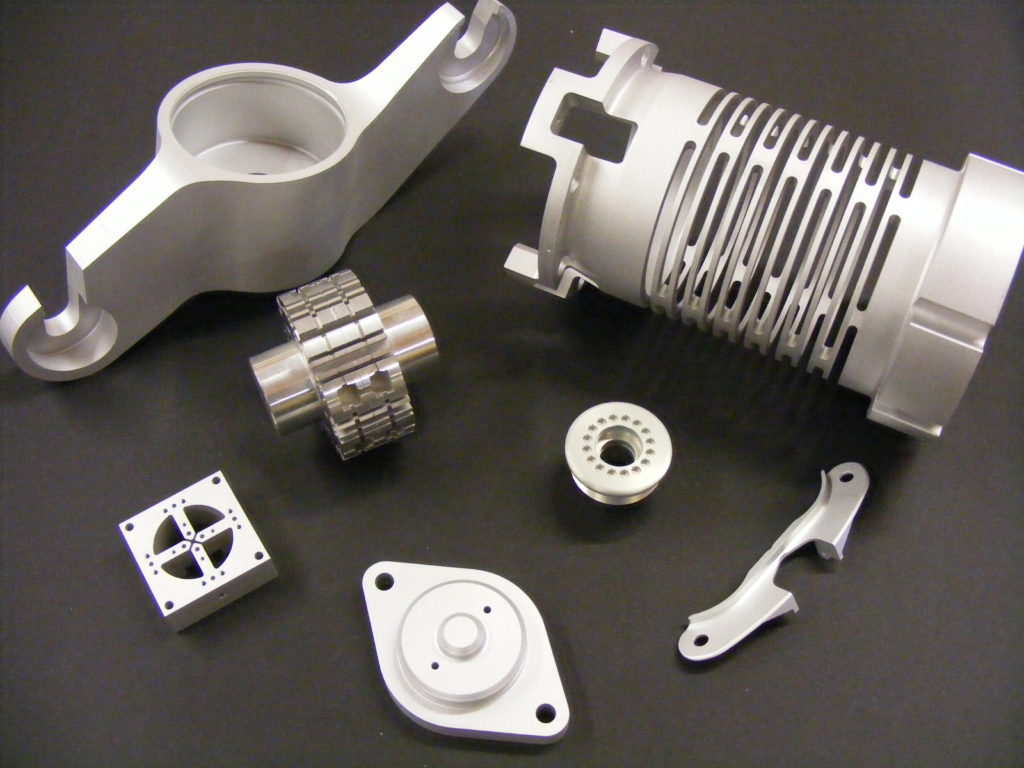

Sub-Contract Machining

As a result of continuous investment our comprehensive modern shop is fully equipped with some of the most up to date CNC equipment.

Our systems and processes, backed by our experienced staff allow us to undertake Prototype machining, R & D, small batch and medium production runs.

All our skilled machinists are trained to the highest standards and all parts are meticulously checked before dispatch using our full complement of calibrated measuring equipment and our systems are all certified to ISO 9001-2008 ensuring full traceability with certification available on request.

Alongside our EDM and CNC expertise, we have a highly motivated team with extensive experience in conventional machining.

This enables us to offer our customers a ‘one-stop-shop’ approach to their machining needs, allowing projects which require specialist and conventional machining to be completed in-house and ensuring that deadlines are met.

Eletcro Discharge Machining

We can produce components from a few millimetres in size, up to a maximum weight of 1 ton, either as one-offs or in batches.

Five axis wire EDM technology enables the economic production of parts that cannot conventionally be produced and as a non-contact process, with very low work holding forces, the EDM method can undertake the production of complex geometric forms.

Rapid economic production of prototypes and low run parts can eliminate or reduce fixture and tooling costs and parts can be immediately used in assembly. With little or no additional finishing and because hardened materials can be EDM eroded, the need for heat treatment of machined parts is eliminated, avoiding potential distortion and ensuring tight tolerances of up to 2 microns can be maintained.

Exotic materials including super alloys, medical grade stainless, titanium, hastelloy, tungsten carbide, molybdenum, aluminium alloys and copper can all be machined. Better utilisation of valuable materials is provided through chip less machining and with wire EDM there is no contact between the cutting wire and the surface, so there is no tooling wear and absolute consistency can be achieved on every machined part.

Why Choose Waveney Precision

Proven track record and over 80 years of combined experience within the engineering industry

Positive Customer Feedback

Our highly skilled engineers use only best working practices

We use only the finest materials and consumables for our processes

Highly experienced working with super alloys, medical grade stainless, titanium, hastelloy, tungsten carbide, molybdenum, aluminium alloys, copper and various grades of steel.

Systematic Internal audits carried out to maintain quality and customer service

BSI ISO 9001 2008

Member of the GTMA

Confidentiality assured

Waveney Precision Ltd. can project manage your required sub contract operations including:

- Material purchasing

- Laser-cutting

- Waterjet cutting

- Fabrication

Plus coating and painting treatments including:

- Powder Coating

- Zinc Plating

- Nickel Plating

- Chrome Plating

- Anodising

- Tufftriding

- Nitriding

- Heat treatment

- Phosphating

- Nitro Carburising

| Capability | Maximum Sizes Handled |

|---|---|

| Die Sinking | Up To “x” 460mm, “y”, 460mm, “z” 520mm |

| Wire Erosion (spark erosion) | Up To “x” 600mm, “y”, 400mm, “z” 420mm |

| Surface Grinding | Up To “x” 450mm, “y”, 200mm, “z” 200mm |

| Milling | Up To “x” 700mm, “y”, 500mm, “z” 500mm |

| Turn/Mill | Up To 200mm diameter x 500mm long |

Machines/Equipment

2 x BA24 Mitsubishi Wire EDM

1 x FA20s Mitsubishi Wire EDM

1 x BA8 Mitsubishi Wire EDM

1 x Ingersoll Centre 400 EDM Sinker

1 x Ingersoll Gantry 500 EDM Sinker

1 x Doosan Turn/Mill Twin Spindle Machining Centre

2 x Doosan Machining Centre with Nikkon 4th Axis

1 x Cincinatti Milacron 750

Surface Grinding

Manual Mill and Turn

Mitutoyo EURO-c-a574 Fully programmable CMM

CAD/CAM

OneCNC

Autocad

Esprit

Solidworks

Bob Cad Cam

Contact Waveney Precision Ltd

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU