Ceratizit UK and Ireland Ltd

The CERATIZIT Group encompasses four specialist brands of Cutting Solutions, with CERATIZIT, Komet, Klenk and WNT, collectively known as Team Cutting Tools. Each brand leads the industry in its respective field of cutting tool technology. To maintain and strengthen this market-leading position, Team Cutting Tools depends on comprehensive R&D and strategic investment across a wide range of industry sectors. It is this dedication to customer excellence that empowers CERATIZIT's customers to maximise productivity, precision, and quality whilst optimising processes and reducing costs.

Customer service remains the key differentiator that establishes Ceratizit UK & Ireland as the industry benchmark. This service continues to evolve through ongoing expansion and investment in its applications sales engineering team, and the technical centre in Sheffield. With Applications Sales Engineers and Technical Sales Engineers located close to customers – wherever they are throughout the UK, these specialists actively collaborate with customers to deliver process improvements and maximise productivity through optimal tooling selection and implementation.

With over 65,000 standard products in the CERATIZIT portfolio and an extensive range of custom solutions, CERATIZIT delivers the right solution for engineers – regardless of the application. CERATIZIT consistently advances the frontiers of new product development to strengthen further customer excellence as well as its reputation for delivering superior products that meet and surpass the demands of contemporary manufacturing.

What You Want – At Your Fingertips

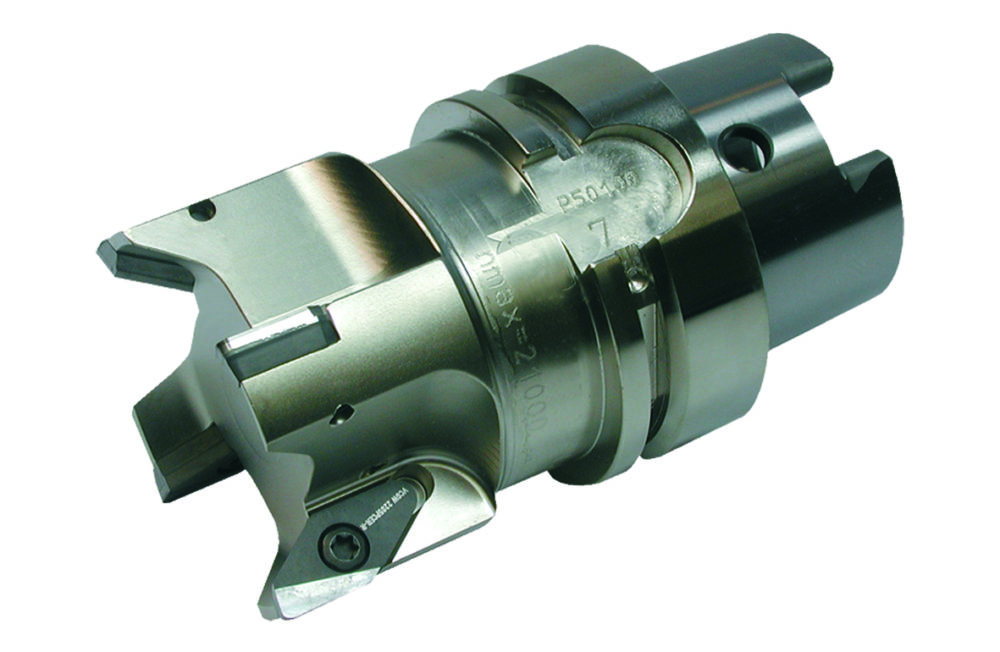

As a global leader with an exceptional breadth of cutting tool solutions and clamping devices, the 2025 edition of the CERATIZIT product catalogue features thousands of standard cutting tool lines. The enhanced product portfolio encompasses everything from cutting tools and clamping technology to machine spindles and tables.

Given such a comprehensive range, CERATIZIT has once again published the latest catalogue in both digital and print formats. The catalogue remains easily accessible on mobile devices through the CERATIZIT App available for complimentary download on both the Apple App Store and the Google Play Store. This provides machine shops with the capability to access and order everything from CERATIZIT – anytime and anywhere.

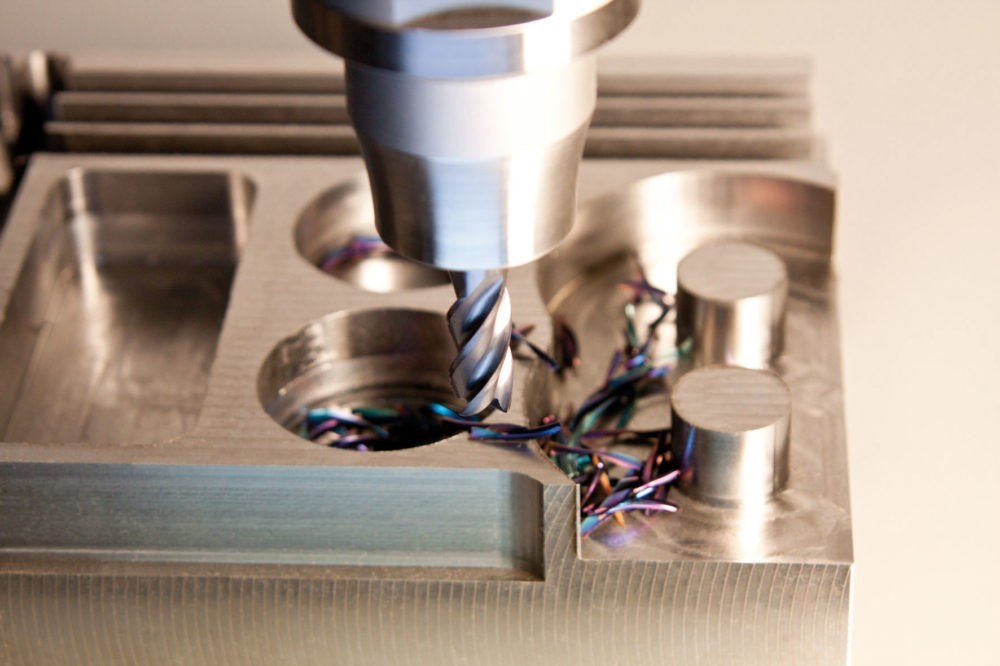

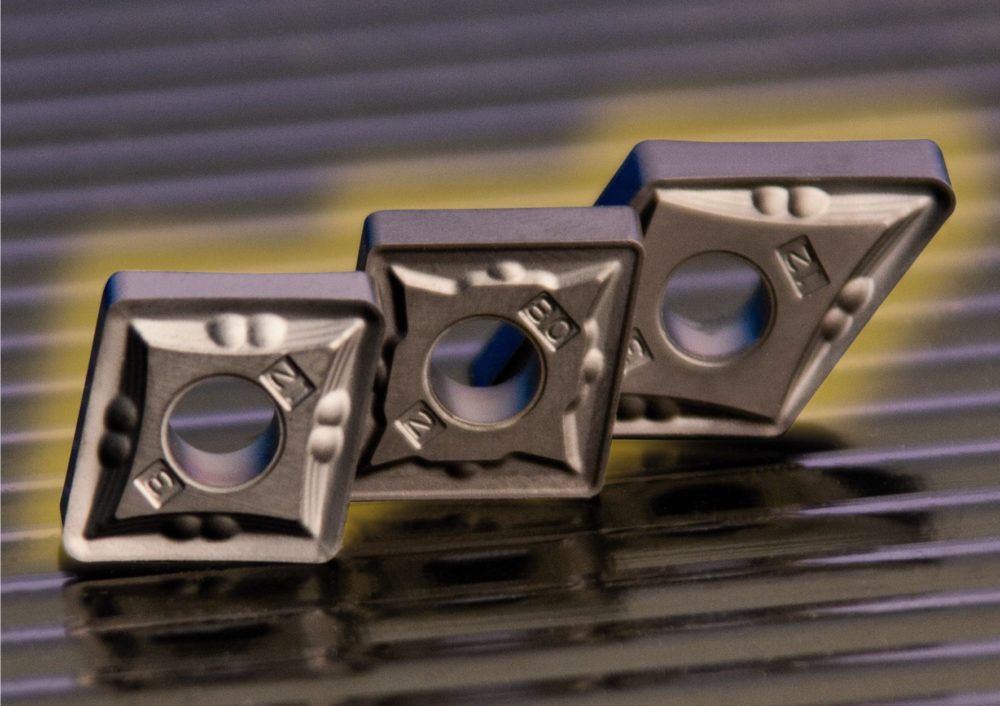

With direct access to the online shop, essential machining knowledge, practical tools like the cutting data collector, delivery status and updates as well as company and product news and insights – you don’t need to look anywhere else for a solution. The latest edition of the catalogue has a wealth of new innovations such as the exciting new MaxiMill – S-Power milling system for cast materials, the MonsterMill ISO-S for nickel-based alloys, and the versatile WTX-UNI drill series. All innovations are characterised by high tool life, optimised geometries, and sustainable materials – developed for maximum efficiency and process reliability in demanding applications.

With the CoreLine series, CERATIZIT demonstrates what robust standard solutions with high quality and attractive price-performance ratios can look like. This product line is specifically aimed at general machining and offers a wide range for small to medium batch sizes – supported by simple ordering processes and short delivery times.

Smart Solutions with Added Value

Where others merely supply tools, CERATIZIT goes beyond convention – as a partner along the entire value chain: From the development of innovative carbides to precise tool production and recycling, the company supports its customers with tailored solutions. CERATIZIT has invested heavily throughout the value chain to bring this concept to life.

Part of this value chain is the increasing awareness of digital applications. With ToolSelect, CERATIZIT now introduces a solution that takes the selection of the optimal machining strategy to a new level: Users can either manually enter workpiece data or upload a 3D model, and within 90 seconds, the system provides up to five suitable tool combinations for milling, drilling, turning, or grooving operations. ToolSelect is fully integrated into the CERATIZIT online shop and offers extensive comparison, filter, and sorting functions for precise fine-tuning.

The digital portfolio is complemented by the Spanflug BUY and Spanflug MAKE applications, which are now part of the CERATIZIT offering through a strategic investment in Spanflug Technologies GmbH. These tools enable even more precise quote calculations based on detailed tool data and open up new synergies in product development, sales, and internationalisation.

Contact Ceratizit UK and Ireland Ltd

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU