Superite Tools

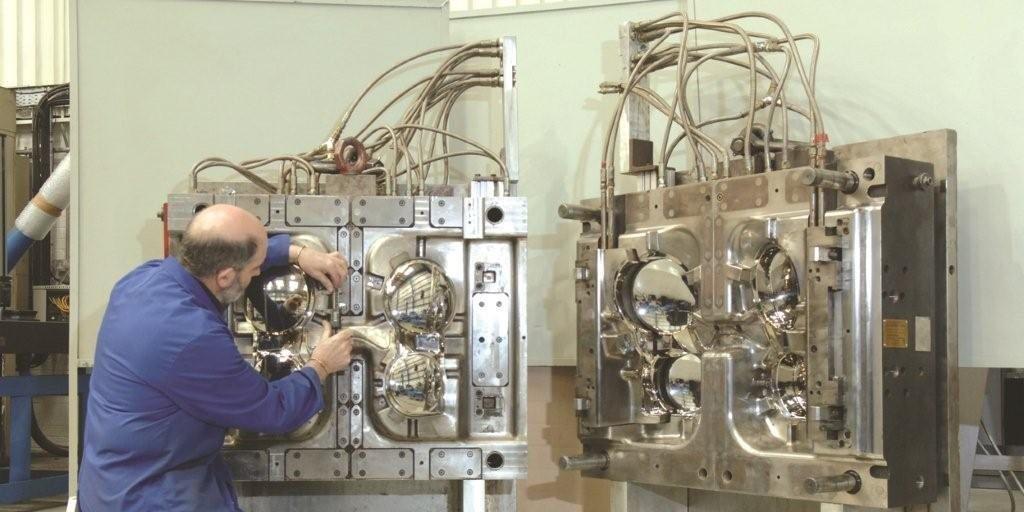

Superite Tools offer a high quality and fast response tool modification and tool repair service for customers nationwide. With a wealth of experience, having opened in 1955, Superite Tools offers a high quality and fast response modification and repair services. The company has expert knowledge on a wide range of tooling for numerous products, across various industrial sectors.

Superite offers a dedicated service for tool modifications and repairs up to 15 tonne

Superite Tools Ltd began designing and manufacturing injection moulds, die casting tooling and press tools in 1955.

With a wealth of experience, they offer a high quality and fast response modification and repair services up to 15 tonnes, for customers countrywide.

This experience has given the company knowledge of a wide range of tooling for numerous products and across various industrial sectors and all our operation is controlled under ISO 9001 procedures and we pride ourselves in delivering a quality service right first time on time.

They can carry out full refurbishment and modifications on any tool up to 15 tonne, ensuring continued production capability for our customers without the expense and time delay incurred in manufacturing a new tool.

Superite no longer manufacture new tooling but offers a high quality, reliable and fast response modification and repair service for customers for:

- Plastic injection mould tools

- Compression moulds

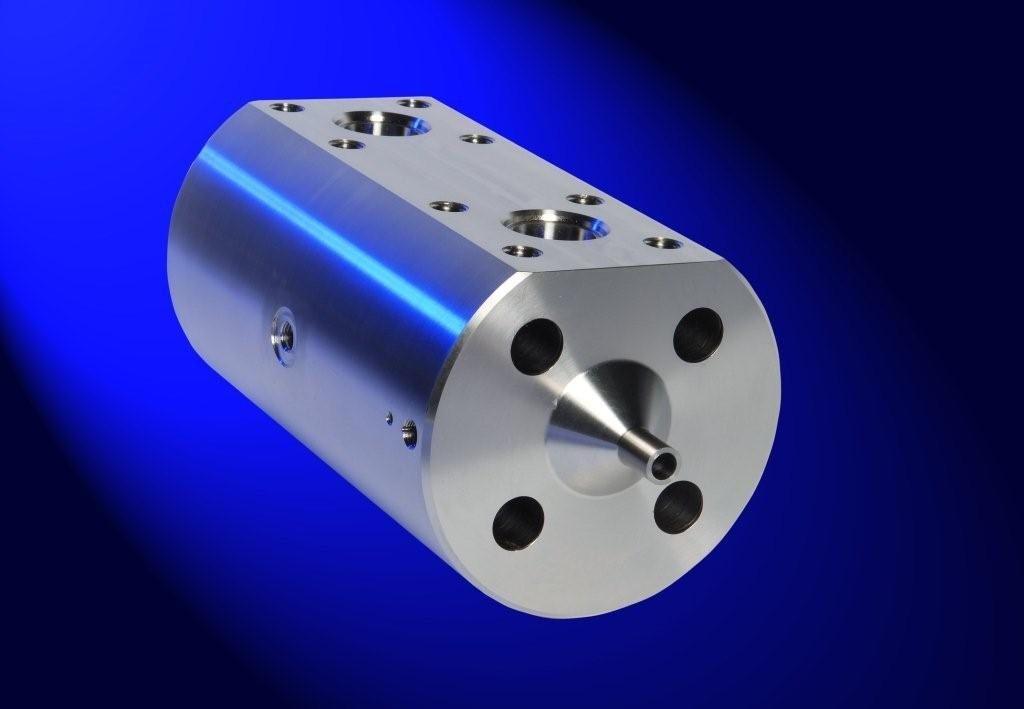

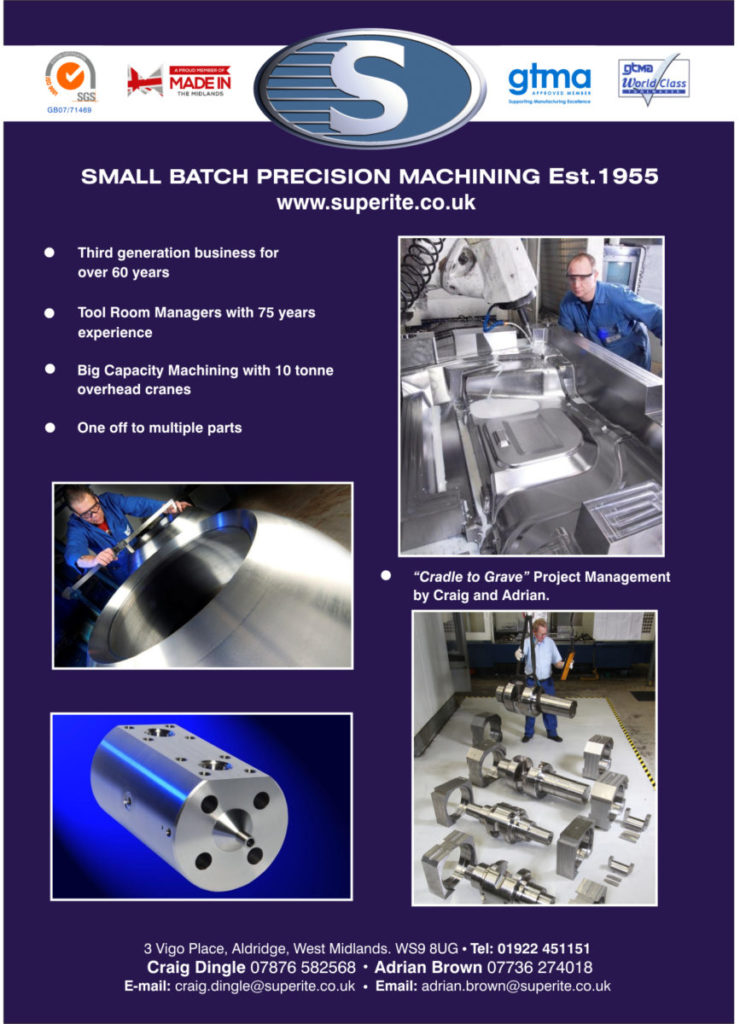

- Precision Machining

- High pressure die cast tooling

- Press tools

- On site bench work

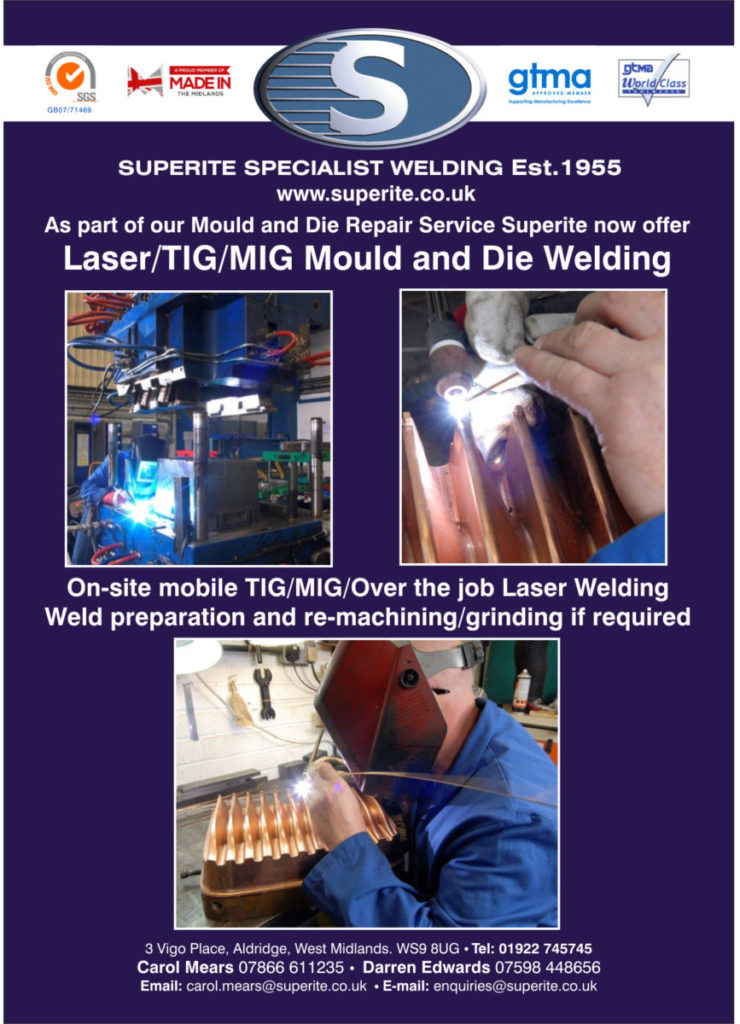

- Specialist welding available on and off site

Tooling Repair and Modification Industry Sectors

At Superite Tools have a wealth of knowledge in all sectors, and pride themselves with experienced engineers to cater for the tooling repair and modifications for a diverse range of clients, across many different industrial sectors.

Their vast range of tooling services that they have developed over the years, guarantees that they are able to exceed customers expectations time and time again.

Superite Facilities & Machinery

ISO 9001 standard facilities and expert machinery include:

- Capacity up to 15 tonnes

- In house CAD / CAM Design

- Extensive Toolroom & CNC Machinery

- Conventional Milling Machinery

- Inspection Equipment

- 38 tonne nationwide transport service

- Highly Skilled Toolmakers / Engineers / Designers

| Capability | Maximum Sizes Handled |

|---|---|

| Die Sinking | Up To “x” 2200mm, “y” 1100mm, “z” 1000mm |

| Surface Grinding | Up To “x” 1800mm, “y” 610mm, “z” 500mm |

| Milling | Up To “x” 2200mm, “y” 1100mm, “z” 1000mm |

| Turning | Up To “x” 800mm, “y”100mm |

| Wire Erosion (Spark Erosion) | Up To “x” 1200mm, “y” 800mm, “z” 440mm |

| Try Out Facilities | Up To “x” 850mm, “y” 850mm, “z”1200mm |

Machines/Equipment

- 1 x Huron TX

- 1 x ONA 460

- 1 x Mikron 1200

- 1 x ONA 360

- 1 x DMG 103V

- 1 x ONA 2030

- 1 x DMG 80E

- 1 x ONA 2060

- 2 x Bridgeport VMC 1000

- EDM Machines – Wire

- High Speed M/C Centres

- 1 x ONA 400E

- 1 x Anayak 1800 M/C Centre

- 1 x Bridgeport Interact Miller

- CNC Turning: 1 x Alpha 550

- Inspection: Mitutoyo 706CMM

- EDM Machines – Sink:

- Surface Finish Microscope

- Baty Profile Projector

CAD/CAM

- Hardware Includes 7 Pentium III Workstations

- Software Includes Delcam Powershape, Autocad 2000

- Duct Draft, Powermill and Pro-E

Contact Superite Tools

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU