Industrial Physics

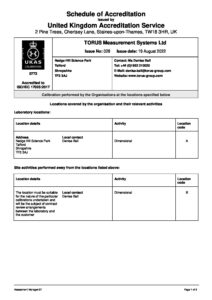

By choosing us, through our testing brand Torus Measurement Systems Ltd, you are choosing a UKAS accredited calibration laboratory. Not only can you rest assured that you are receiving the most appropriate service for your requirements, but you will also discover that the UKAS ‘symbol’ on your documentation brings with it national and international recognition to your business.

You should be confident that your goods, services, and their component parts are based on measurements taken with correctly calibrated measuring equipment. There is a way to ensure that your organisation adheres to the requirements of its ISO 9001 certification, which also means you can have increased confidence that any calibration carried out on your behalf is done so in a reliably competent, consistent, and impartial manner and to the correct degree of accuracy. The international standard ISO/IEC 17025 defines what is required of a laboratory in order for it to demonstrate both technical competence of the personnel and the availability of all the technical resources needed to produce reliable data and results for a defined set of tests, measurements or calibrations.

Choosing a competent calibration laboratory is important in maintaining your reputation as a responsible business. It is therefore paramount that you choose to use the service of a laboratory whose competence has been confirmed by an independent, authoritative third party such as UKAS. Industrial Physics, through our testing brand Torus Measurement Systems Ltd, are UKAS accredited and rigorously audited to BS EN ISO/IEC 17025 procedures, ensuring you receive the best possible service.

UKAS Calibration Service

UKAS Calibration Service

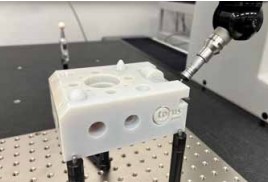

Industrial Physics, through our testing brand Torus Measurement Systems Ltd, provide UKAS Calibration Services for dimensional measurement offering both 1st Principle and CMM capabilities, our expertise and knowledge provide a complete UKAS Calibration Service for the dimensional measurement of components, including but not limited to; machined parts, castings, injection mouldings, tooling, receiver and positions gauges, jigs, fixtures and final products. Master and Artefact Calibration Torus also provide a comprehensive UKAS calibration and recall service for all Masters and Artefacts.

UKAS Verification and Service

UKAS Verification and Service

Industrial Physics recommend an annual UKAS verification and service of all CMM equipment, due to dust and airborne contaminants settling on CMM scales, belts, drives, pipe-lines and guideways. This ensures minimal impact on production and manufacturing, whilst providing verification that the CMM continues to satisfy your measurement requirements.

CMM Spares and Accessories

CMM Spares and Accessories

Industrial Physics provide independent onsite consultation to determine the best solution for your application. We stock a wide variety of spares and aim to deliver within 48 hours. Torus are also able to source components from multiple OEM’s and can be your ‘one-stop’ shop saving you time and effort. Industrial Physics also supply our own range of metrology tables and enclosure, all designed and built in-house to your requirements.

CMM Training

CMM Training

Choosing Industrial Physics as your CMM training provider means you are benefiting from a training team with years of CMM experience. Our team of experts have developed a training program that is structured to not only meet all of the essential CMM training requirements, but to also allow users to tailor the course to their own needs and focus on the areas of training that are most beneficial to you and your business.

Based on your requirements, CMM training courses can be delivered one-to-one or in small group classes and can be conducted on-site, or in our own state-of-the-art UKAS laboratory.

UKAS Arm Verification

UKAS Arm Verification

Industrial Physics, through our testing brand Torus Measurement Systems Ltd, provide a full UKAS Arm Verification service covering a wide range of industries

We recommend an annual UKAS verification of all measurement Arms, ensuring confidence in the Arm performance within the working environment, to ensure a minimal impact on production and manufacturing, whilst providing verification that the Arm continues to satisfy your measurement requirements.

UKAS Height Gauge Verification

UKAS Height Gauge Verification

Industrial Physics, through our testing brand Torus Measurement Systems Ltd, provide a full UKAS Height Gauge Verification across a wide range of industries.

We recommend an annual UKAS verification of all complex height gauges ensuring confidence in the gauge performance within the working environment. This ensures minimal impact on production and manufacturing whilst providing verification that the height gauge continues to satisfy your measurement requirements.

Sub-Contract Inspection

Sub-Contract Inspection

Industrial Physics provide a wide range of Sub-Contract Inspection services to meet your inspection requirements. Torus’ inspection team work closely with our customers to meet their measurement requirements; our expertise and knowledge can help provide you with a quick, easy and professional reporting. Our experience across a wide range of industries including medical, automotive, aerospace, presswork, injection molding, packaging and more, allows us to tailor part measurement and inspection services to suit each customer’s inspection needs; from single first articles to large-scale volume batches.

Sub-Contract Programming

Sub-Contract Programming

Industrial Physics provide part programming for a wide range of industries using our team’s expertise and experience. Our team of experienced engineers can help alleviate your programming load to create high quality, ready-to-go programs catered to your drawing requirements. Our experience across a wide range of industries means we can create programs for even the most demanding components, with or without CAD data.

Programs can be created offline or live on a sample component in our UKAS Accredicated Laboratory, ensuring program prove out is completed without disruptions to your production/inspection schedule. Can’t send a sample?

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU