REM Systems Ltd

REM Systems – Your Expert Partner for Complete Manufacturing Solutions

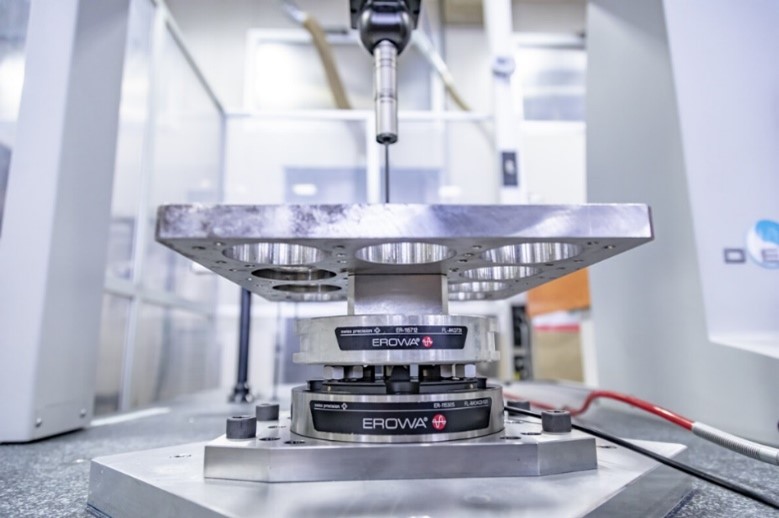

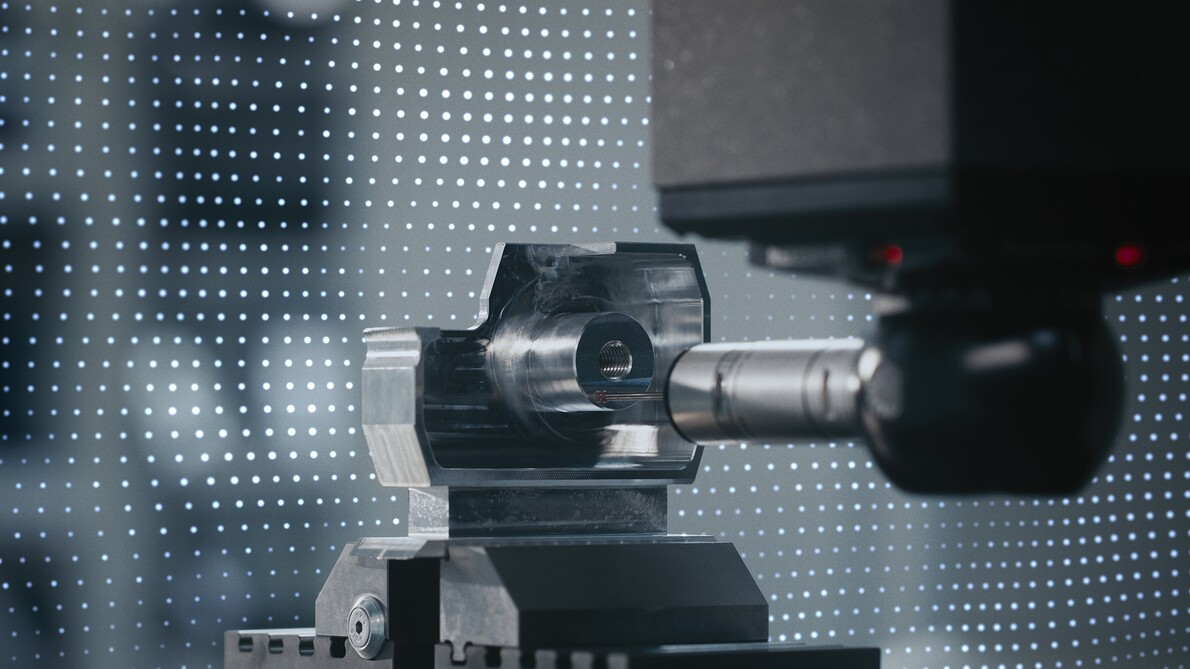

At REM Systems, we specialise in providing customised, modular solutions for workpiece clamping, presetting, measuring, automatic loading, and data transfer. Using EROWA technology, our mission is to help you make cost-effective and sustainable investments that enhance your production systems. Whether your machine tools come from different manufacturers or generations, we seamlessly integrate them across various manufacturing processes.

Unlock the Full Potential of Your Manufacturing Facility

In a world where manufacturing meets progress, EROWA blends Swiss precision with cutting-edge technology. The advanced solutions offer unparalleled reliability and efficiency, unlocking new levels of productivity for your business.

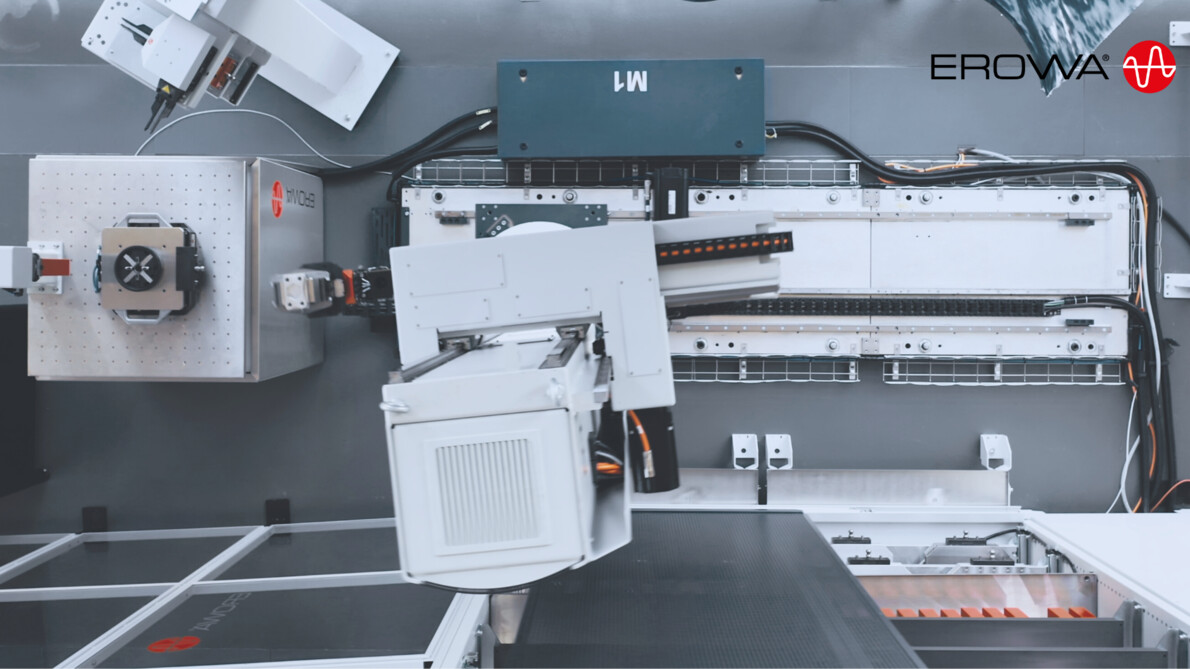

For workshops that handle a wide variety of parts, EROWA’s automation solutions maximise unattended production, reducing labour costs while boosting efficiency. Intelligent job scheduling ensures continuous operation, even during non-work hours. EROWA’s versatile pallet-based handling system accommodates a wide range of part sizes and shapes, automating job changes and integrating smoothly into modern workshops to minimise downtime.

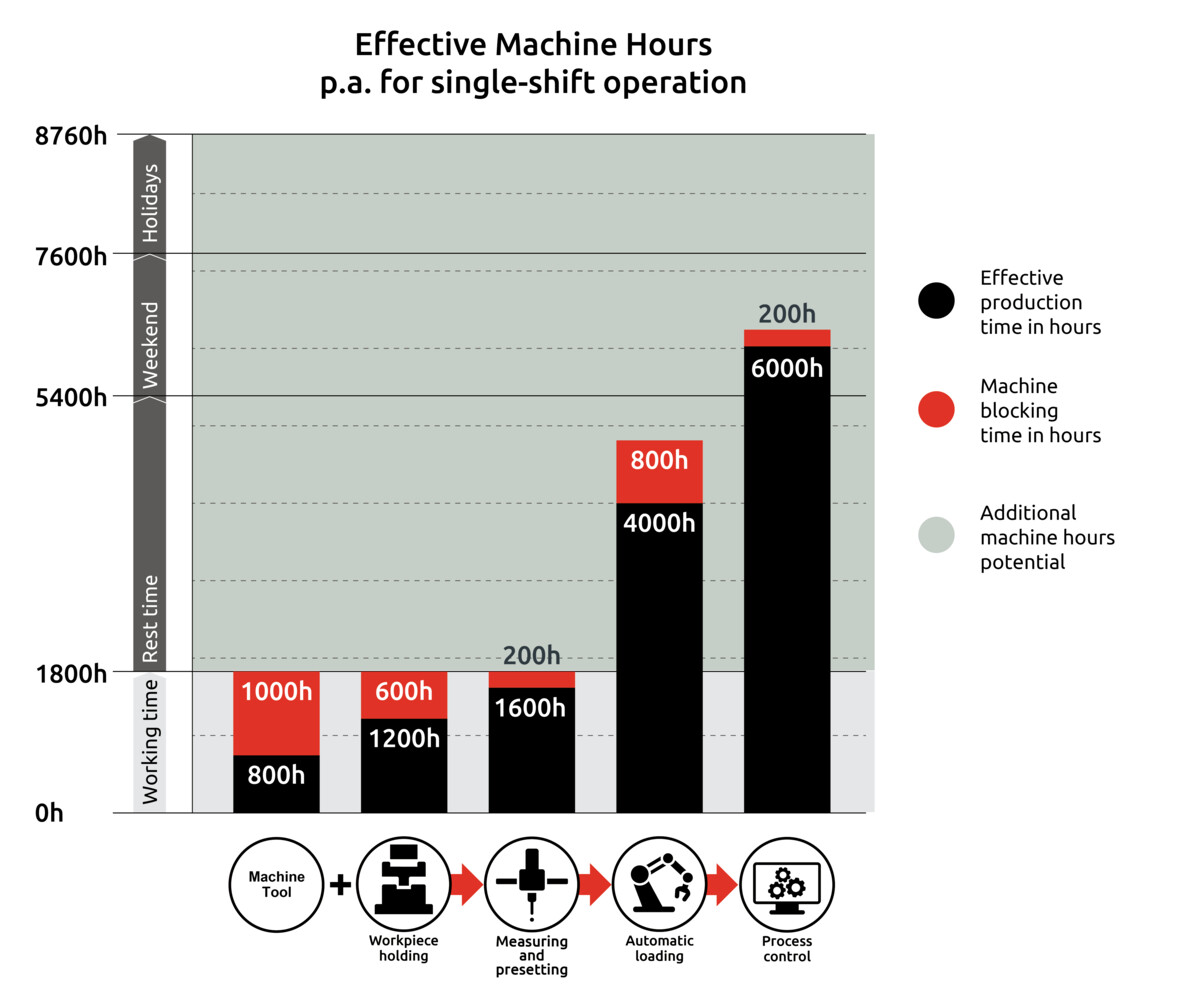

Achieve 8,760 Hours of Productivity per Year

With EROWA’s flexible manufacturing solutions, you can achieve up to 8,760 productive hours per year by eliminating downtime. The approach involves four key stages:

1. Standardisation – Increase productivity from 800 to 1,200 hours.

2. Organisation – Reach up to 1,600 hours.

3. Automation – Achieve 4,000 hours of continuous, 24/7 operation.

4. Integration – Extend to 6,000 hours of annual operation.

Each stage represents a step towards a future where automation and human craftsmanship converge, creating a legacy of excellence. EROWA’s automation systems – including tooling technologies, pallet loading, and zero-point tooling – have the power to transform your workshop, optimising operations for greater efficiency, increased output, and a quicker return on investment.

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU