Renishaw Plc

Renishaw is a global company with 50 locations in 30 countries. They have expertise in measurement, motion control, spectroscopy, and precision machining. The company supplies products and services used in applications as diverse as jet engine and wind turbine manufacture, through to dentistry and brain surgery. Renishaw is also a world leader in the field of metal 3D printing.

Our Metrology products help manufacturers to maximise production output, significantly reduce the time taken to produce and inspect components, and keep their machines running reliably. In the fields of industrial automation and motion systems, our position measurement and calibration systems allow machine builders to manufacture highly accurate and reliable products. The product range includes:

Additive manufacturing (AM)

Advanced metal AM systems for direct manufacturing of 3D-printed metallic components. A total solution is offered from systems, materials, ancillaries and software through to consultancy, training and support for a range of industries including industrial, healthcare and mould tooling.

Co-ordinate measuring machine (CMM) products

Sensors, software and control systems for three-dimensional CMMs, including touch-trigger and scanning probes, automated probe changers, motorised indexing probe heads and 5-axis measurement systems, which enable the highly accurate measurement of manufactured components and finished assemblies.

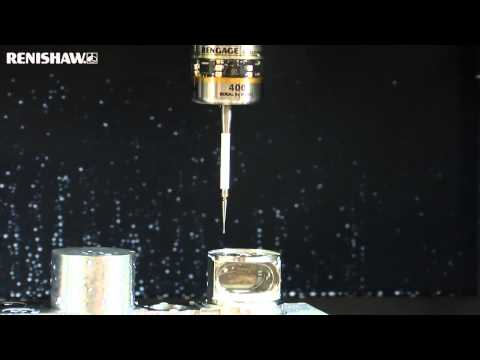

Machine tool probe systems

Sensors and software for computer numerically controlled (CNC) metal cutting machine tools that allow the automation of setting and on-machine measurement operations, leading to more productivity from existing machines and reductions in scrap and rework. These include laser tool setters, contact tool setters, tool breakage detectors, touch probes, contact scanning systems and high‑accuracy inspection probes.

Styli for probe systems

Precision styli that attach to probe sensors for CMMs, machine tools and Equator™ gauging systems to ensure that accurate measurement data is acquired at the point of contact.

Performance testing products

Calibration and testing products to determine the positioning accuracy of a wide range of industrial and scientific machinery to international standards, including a laser interferometer, rotary axis calibrator, wireless telescoping ballbar and software for data capture and analysis.

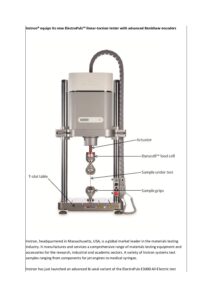

Gauging

The Equator gauging system enables process control by delivering highly repeatable, thermally insensitive, versatile and flexible gauging to the shop floor, both as a standalone device and as part of an automated manufacturing cell. Combined with IPC (intelligent process control) software, the Equator gauge provides the functionality to fully automate tool offset updates in CNC manufacturing processes.

Fixtures

Modular and custom fixtures used to hold parts securely for dimensional inspection on CMM, vision and gauging systems.

Position encoders

Position encoders that ensure accurate linear and rotary motion control in a wide range of applications from electronics, flat panel displays, robotics and semiconductors to medical, precision machining and print production. These include magnetic encoders, incremental optical encoders, absolute optical encoders and laser interferometer encoders.

Contact Renishaw Plc

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU