Verus Metrology

Verus will partner with our clients to deliver, install and support complete turnkey and validated bespoke metrology fixture solutions, anywhere in the world.

15 Years of Advancing Metrology Technologies

For over a decade, Verus Metrology Partners’ commitment to providing full turnkey metrology fixture solutions, have been evolving the way our clients conduct their measurement processes.

We specialise in the measurement of complex plastic component geometries, utilising our world-leading tailored metrology fixtures, along with our expert in-house measurement capabilities, we ensure our metrology solutions maximise productivity across our clients’ inspection process.

Our clients come to us from across the globe, looking for a metrology solution that benefits them. Keeping this in mind, our continued pursuit of market-leading innovation, quality and customer service, backed by investment in our people and processes, we continue to push the boundaries surrounding the measurement process searching for that solution.

Verus Metrology Partners are proud to be classed as world-leaders in Turnkey Metrology Solutions providing metrology services globally from both our UK-base in Nottingham, England and our headquarters in Co. Sligo, Ireland

At Verus, we are committed to supporting our clients beyond the delivery of our fixtures. We offer full turnkey solutions, providing fixtures with a life cycle support guarantee, giving our clients that extra bit of added value.

Our two main areas of expertise are:

Turnkey Solutions

We strive to deliver a complete turnkey solution that incorporates metrology fixture design, fixture manufacture, qualification, validation, fixture programming and on-site fixture installs. Consisting of a team of metrology experts, sophisticated software, and a strong emphasis on advancing the process of measurement, our quality service ensures our metrology solutions maximises clients’ metrology efficiencies throughout the measurement process.

Verus Metrology Partners delivers a tailored subcontract inspection service that provides you access to the OEM expertise, experience and innovative technology our professional metrology inspection team offers.

Dimensional Inspection – Verus Metrology has made massive investments over the years in state-of-the-art metrology standards and machines. By utilising advanced measuring instruments and innovative technology, the Verus team can rapidly generate accurate verification of clients’ designs and manufacturing processes. We then compile this data into a comprehensive metrology report made available to the client.

From First Article Inspections through to Fit & Function Investigations, the Verus Dimensional Inspection service allows clients to shorten production cycles, identify and correct component problems, resolve disputes, improve quality controls and lower overall operational costs.

Process Verification – We understand the vast amounts of time and resources required to complete the validation process. Consequently, this can often interrupt in-production metrology.

For our partners, overall Process Validation is always ongoing. Accordingly, it plays a role in almost every stage, from initial development to production and upscaling.

We ensure our clients components are in production ahead of schedule with our 15 in-house metrology systems using our custom metrology fixtures and a rapid validation service that supports our clients during Process Verification, with no interruptions.

This is based on three key components; speed, clarity, and equivalency.

Verification & Certification – Verus Metrology Partners provides an accredited and traceable Certification & Verification service to our wide range of global clients, benefiting from our in-house expert metrology engineers. We provide Certification & Verification on:

Custom Metrology Fixtures – In line with international standards, Verus engineers carry out a Verification & Certification Process on all our metrology fixtures following their completion. This process involves an examination of each metrology fixture to ensure it is performing and functioning accordingly.

Non-Standard/Standard Tailored Gauges – We offer a unique partnership with our clients to verify and certify their non-standard custom gauges used for in-process checking. By working closely with our clients, it has assisted us in further enhancing our verification methods used for testing custom gauges. This has resulted in a superior metrology verification process in which we and our clients have full confidence in.

Metrology Lab – Verus Metrology Partners offers a premium metrology lab providing fast and reliable dimensional inspection, measuring instrument calibration and on-site calibration services. The metrology lab is overseen by our highly qualified Metrology Manager aided by a team of expert Metrology Engineers and Technicians.

Facilitating the need for Accurate Dimensional Measurement, our ISO:17025 compliant metrology lab offers a wide diversity of machine types and capacity with all our CMMs and Vision Systems being placed in a 24-hour monitored temperature-controlled environment. Serviced and calibrated each year our entire selection of CMMs and Vision systems are fully traceable to international standards.

To request a Sub-Contract Metrology quote, Click Here.

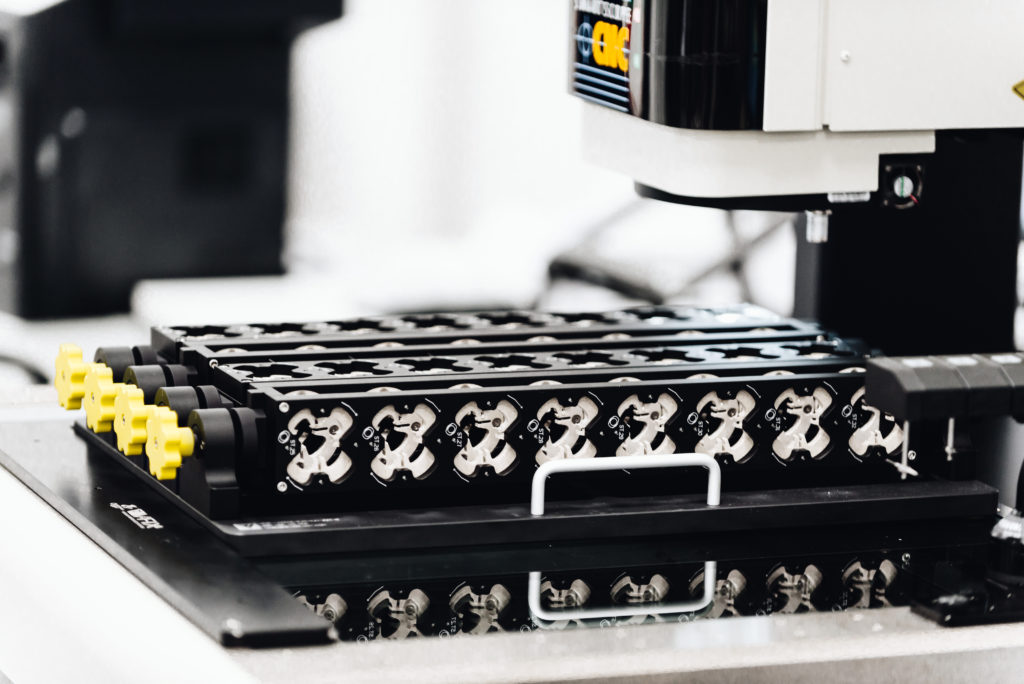

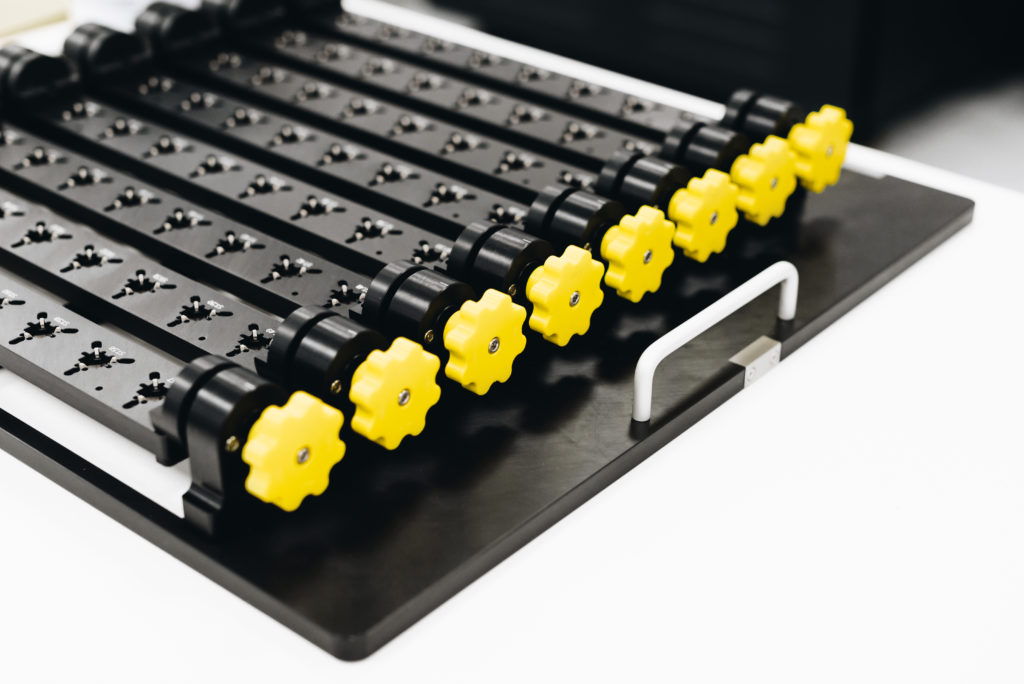

Our Fixtures are designed to reduce operator interaction and to allow the maximum number of measurements to be taken with the minimum number of setups.

Fixture Design – At Verus, we partner with our clients to design and develop custom metrology fixtures. The collaborations allow our design team to work closely with the client to create initial concepts and single station prototypes along with extensive and detailed project schedules.

Metrology Fixture Manufacturing – We provide the highest quality of metrology solutions to our clients through our full in-house manufacturing facility, enabling us to improve productivity and increase throughput. From larger, more difficult components to smaller, intricate parts, our world-leading CNC machining teams save our clients time and money by producing a stable, reliable and repeatable process each time.

Metrology Fixture Qualification – Verus Metrology strongly believes in providing our clients with a metrology inspection fixture that will operate to the highest of standards. To meet this, all Verus’ tailored metrology fixtures have a Gauge R&R performed on them. The Gauge R&R studies carried out on our fixtures aim for a GR&R variation of less than 10% of the tolerance range.

Metrology Fixture Programming – Our expert Metrology Engineers can create, verify and install custom metrology fixture programmes on multiple CMM or Vision Systems. They variety of machines types we work with along with our capacity enables Verus to offer individually tailored solutions designed to meet each client requirement.

To request a Metrology Fixture quote, Click Here.

Delivery, Installation and Support

Once our client receives the fixture, we can send an engineer out to provide installation support. The Applications Engineer will monitor and coordinate the installation process, providing support throughout the entire life cycle of the metrology fixture.

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU