Vision Engineering Ltd

Founded in 1958, Vision Engineering Ltd is a global leading-edge manufacturer of patented ergonomic stereo microscopes, digital inspection microscopes, CMM and non-contact measuring systems. Our unique patented eyepiece-less microscopes save manufacturing companies many man-hours, reduce materials wastage and ensure quality and conformance to required specifications.

Innovative award winning high quality microscopes, 3D visualisation technology and metrology systems that save manufacturing companies time, improve quality, reduce materials wastage and enable news ways of collaboration.

Stereo Inspection

Mantis is an ergonomic revolution that is now the benchmark for high performance stereo magnification. Stunning 3D imaging and unrivalled ease of use and comfort for any manufacturing inspection or assembly task requiring magnification up to 20x.

Queens Award winner Lynx EVO adds zoom capability up to 240x, 360 degree oblique and direct viewing and superb ergonomic operation options to create the complete high magnification visual inspection package.

Digital Inspection

EVO CAM II – Capable. Powerful. Adaptable. EVO Cam II is a powerful, versatile, yet easy-to-use, high definition digital microscope. Flexible configuration options including a 360 degree oblique and direct viewer deliver excellent image quality, the ability to see all round your subject and optical magnification up to 725x; digital zoom takes you even further.

VE CAM – Quick. Easy. Compact. VE CAM full HD digital microscope system for quick and accurate inspection right where you need it. High quality custom-made optics and digital features combine for superior performance. Ideal for visual inspection or manufacturing quality control.

Makrolite 4K – Ultra HD for inspection. Makrolite 4K digital microscope simplifies your visual inspection, image capture and measurement tasks with the exceptional quality of Ultra High Definition image resolution.

Digital 3D Inspection

DRV-Z1 – The future of optical inspection is here. The incredible DRV-Z1 (Deep Reality Viewer) is the world’s first and only digital stereo inspection system which creates full 3D HD images which ‘float’ in front of your eyes. No special glasses or goggles are required. DRV is revolutionising the way organisations and teams collaborate, enabling ‘view, capture and share’ of 3D images of the samples they are studying.

Non-Contact Metrology

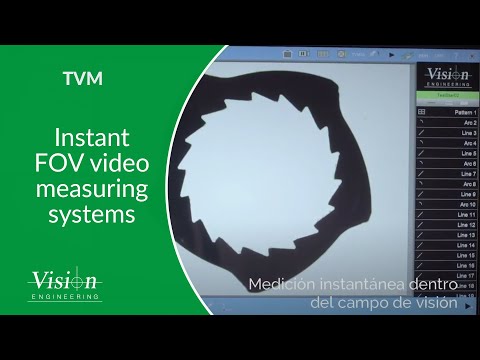

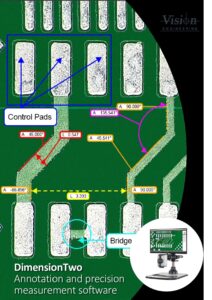

TVM – Measure any shape in an instant. When you need to measure parts and components quickly and in large numbers – regardless of their shape – you need a TVM digital measuring microscope. Simply place the subject on the stage for rapid measurements. TVM is ideal for taking 2D measurements of multiple subjects, when fast throughput and ease of use are essential requirements, and a great choice for a shop floor non-contact measurement system.

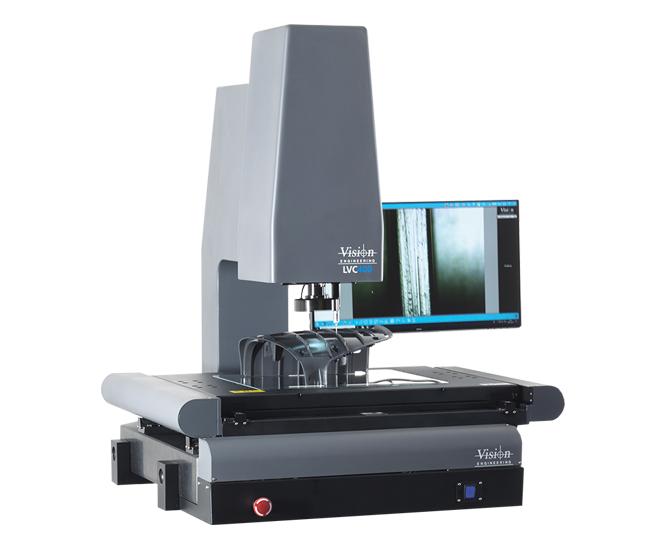

For larger measuring tasks choose LVC Fully automated 3-axis measurement system. Extraordinarily capable, but surprisingly easy to use, Vision Engineering’s LVC400 and LVC200 measuring systems have the power and versatility to meet the needs of demanding manufacturing environments.

Shop floor CMM

Deltron is a robust CNC CMM with compact footprint for high levels of measurement accuracy. For those with limited shop floor space, Deltron is a robust and accurate CNC coordinate measuring machine, combined with compact footprint, but with substantial construction to ensure stability.

For more information about our exciting inspection, 3D visualisation, and measurement technology visit www.visioneng.com

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU