Mahr UK & Mahr Federal

Mahr are the one of the largest manufacturers of precision measurement metrology systems and inspection tools in the world today. Having celebrated over 150 years of success Mahr continue to provide innovative solutions for a wide variety of metrology applications. The Mahr UK team has continued it’s expansion this year and this will strengthen our ability to support UK customers in terms of technical advice, contract measurement and turnkey solutions. As well as supplying metrology systems and inspection tools the Mahr group also manufacture spinning pumps and rotary stroke bearings.

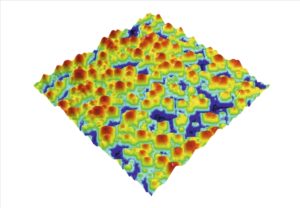

Surface Finish Gauging

Mahr offer an extremely wide range of surface roughness gauges and systems. From the portable MarSurf PS10 Unit to our multi axis XP CNC station Mahr offer a solution for any application. Mahr have continued to develop the well known MarSurf range and this now includes both Confocal Microscopy and White Interferometry Systems for non-contact 3D surface analysis.

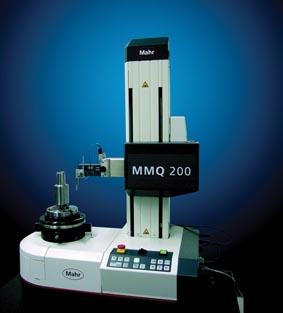

Form Measurement

In today’s world it is not unusual to find Geometric tolerances such as roundness to be no more than 5 micron and sometimes even below 1 micron. To ensure compliance with these tolerances it is usually required to use a formtester and Mahr have a comprehensive portfolio of such machines. From the entry level MMQ100 manual machine up to the market leading MFU100 Mahr can ensure the right solution for your requirements.

Calibration Systems

Today Mahr are the world leader in terms of calibration machines supplied throughout the world. Mahr have a long history in this field and since the ULM and SiP ranges were incorporated into the Precimar family of machines Mahr has enforced it’s position at the leader in terms of products and solutions for both gauge calibration and ultra precise measurement. As well as length calibration systems Mahr also produce fully automated dial gauge calibration systems (Precimar ICM 100P) and gauge block calibration systems (Precimar 826).

Shaft Measurement

MarShaft measuring machines are primarily aimed at precision measurement of components on the shop floor enabling as fast as possible verification of results. The range has both tactile and non contact solutions (MarScope) depending on the application task. The MarScope can cater for parts up to 1M whereas the MarShaft tactile systems have scope to measure up to 2.4M.

Air Gauging

Air gauging is still regarded as the optimum solution for precision measurement of diameters on the shop floor. Air gauging is robust, self cleaning and can repeat down to less than a micron. The tooling can also be designed to measure more complex features such as straightness, squareness and taper.

Special Gauging

Mahr have a rapidly expanding division focused purely on the design and build of special gauging fixtures. If you need a robust solution to measure quickly and accurately talk to Mahr.

Precision Gauge

Mahr’s Precision Gauge range contain thousands of different hand held inspections tools and gauges. The Mahr range includes verniers, micrometers, height gauges, indicators, bore gauges, gauge block and much more.

Contact Mahr UK & Mahr Federal

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU