Roemheld UK Limited

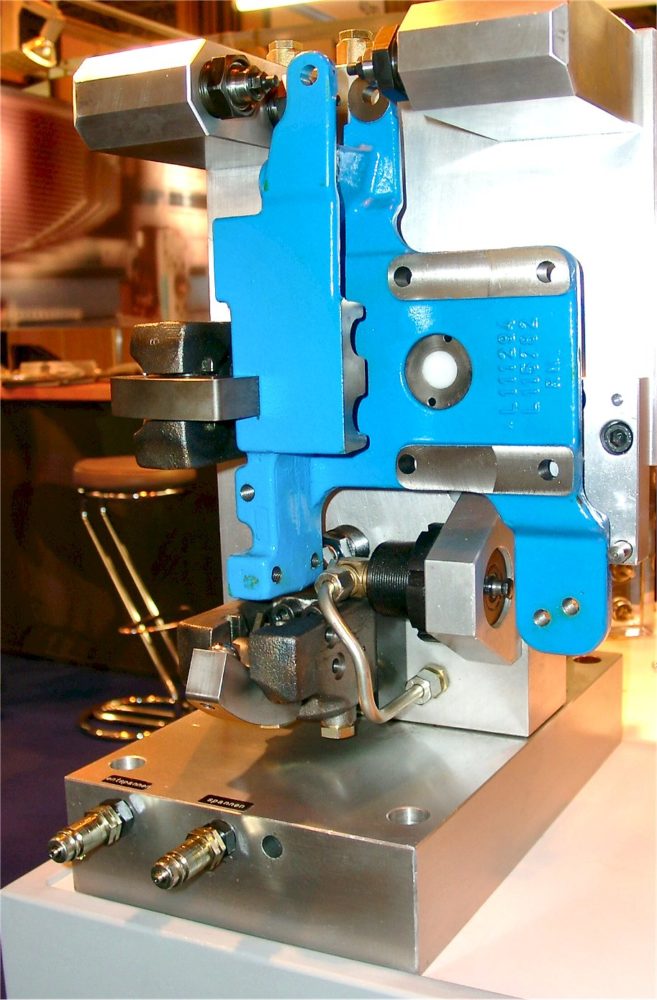

Roemheld delivers workholding solutions to customers that increase throughput while reducing handling times, material wastage, and cycle times. These can include hydraulic swing clamps, zero point mounting technology, 5-axis clamping, and magnetic clamping for use in quick die change and quick mould change.

GTMA FEATURED COMPANY

Roemheld (UK) delivers workholding solutions that increase throughput while reducing handling times, material wastage and cycle times.

These include:

· Hydraulic swing clamps, block cylinders, work supports and accessories

· Hydraulic swing clamps, block cylinders, work supports and accessories

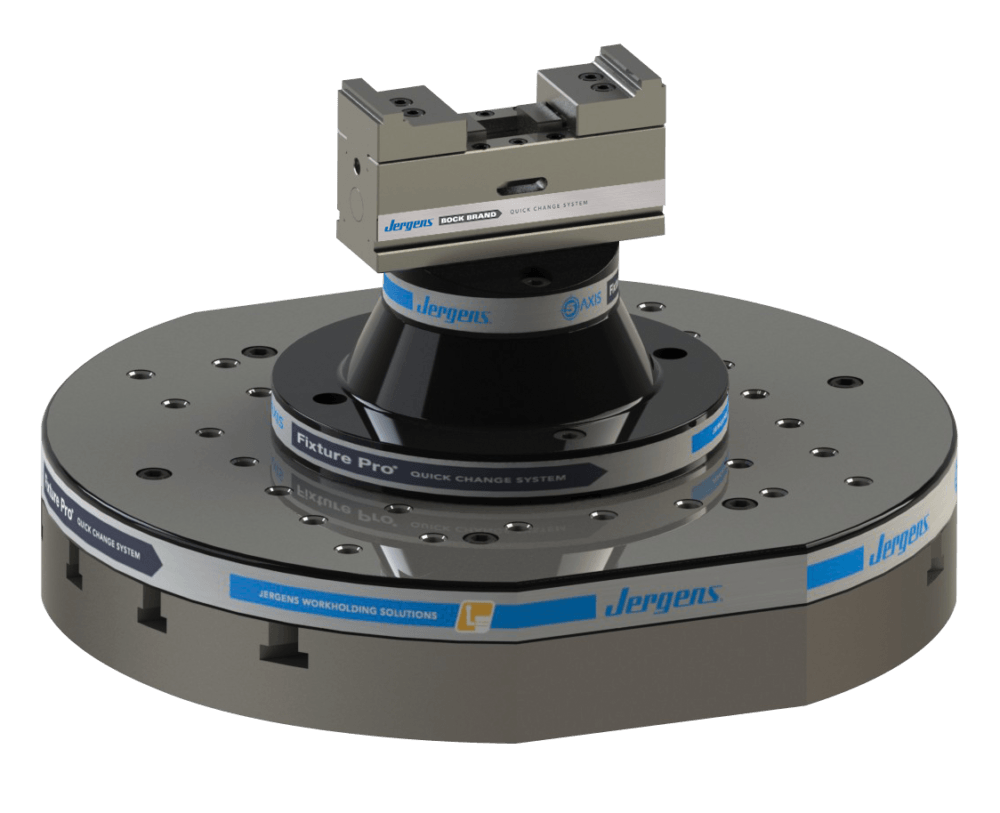

· Zero point mounting technology

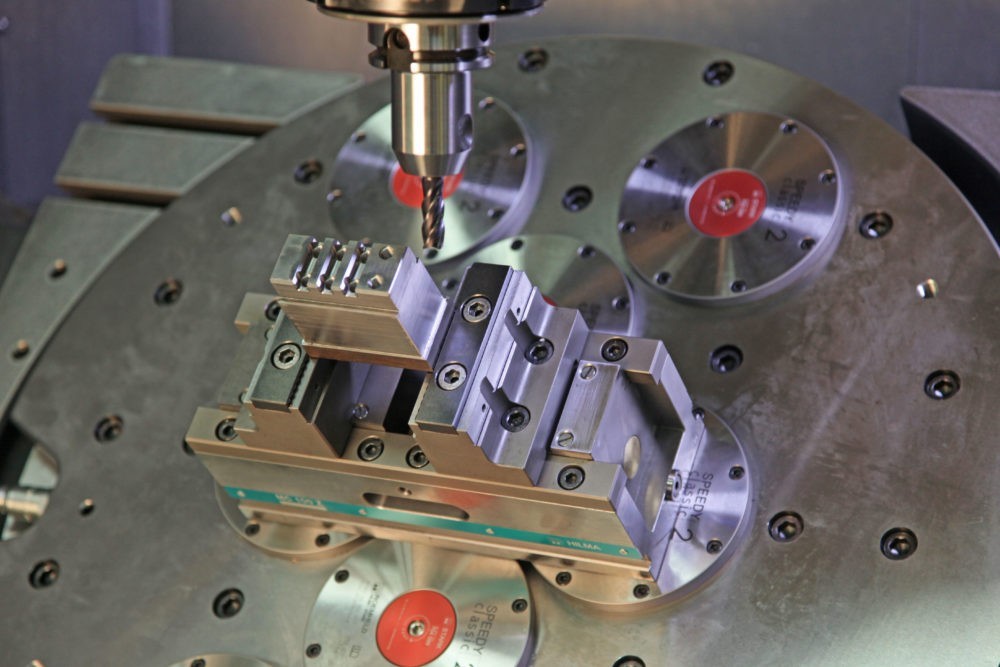

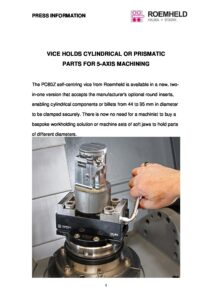

· Vice systems including 5-axis clamping

· Magnetic clamping for use in quick die change and quick mould change

· Assembly equipment and handling technology

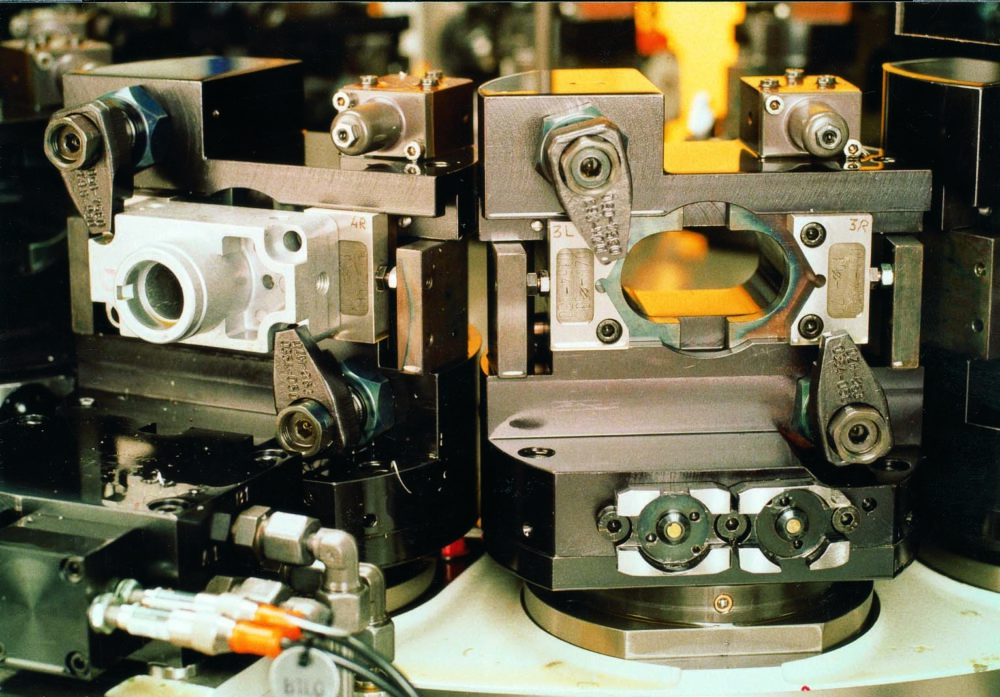

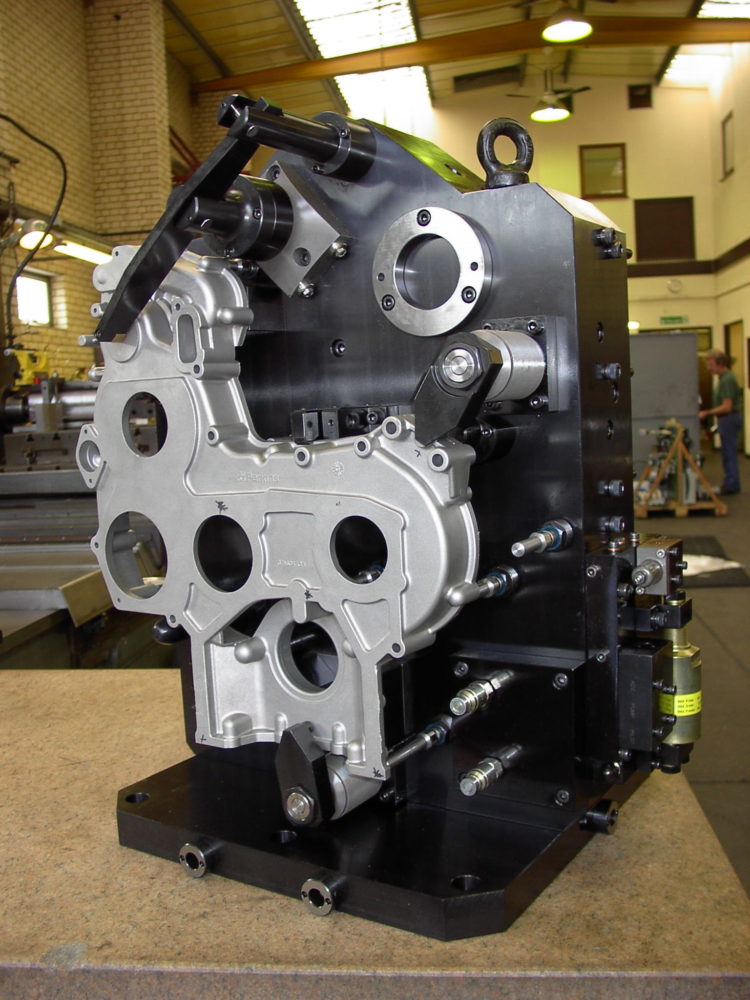

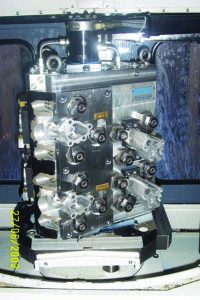

Roemheld offers a complete range of hydraulic clamps, work supports and accessories for use in hydraulic workholding fixtures. Through the application of high pressure (up to 500 bar) smaller clamps can be used to reduce costs and provide more parts per fixture, thus improving productivity.

Roemheld clamps provide high clamping forces and are designed for leak-free operation which means that even if the hydraulic supply is removed, the clamps will still be effective.

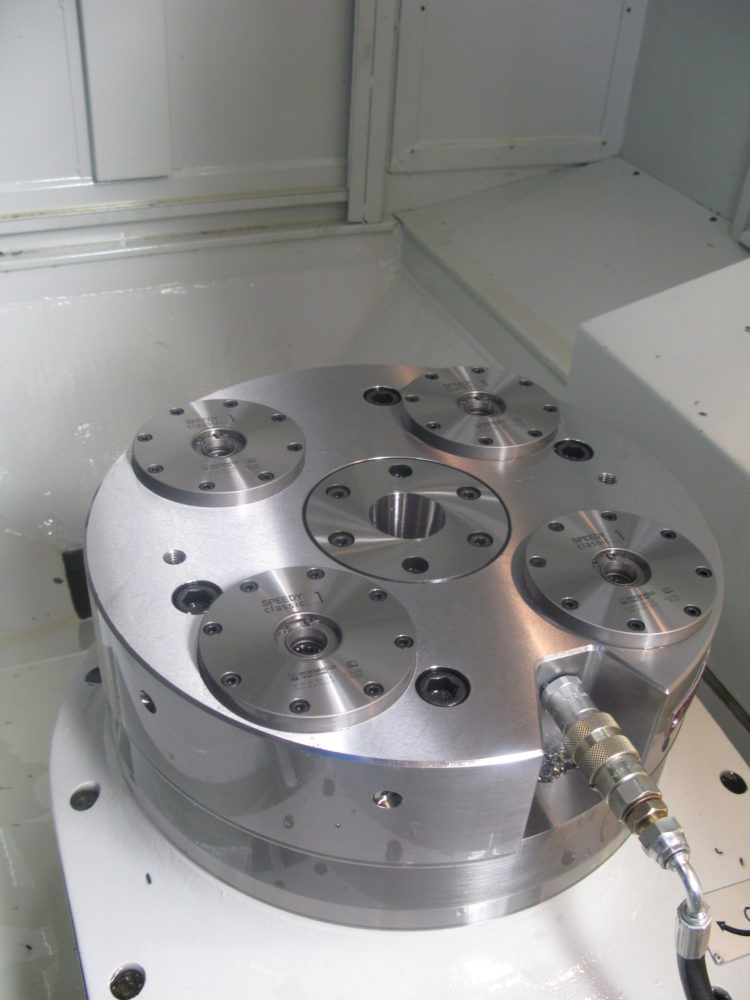

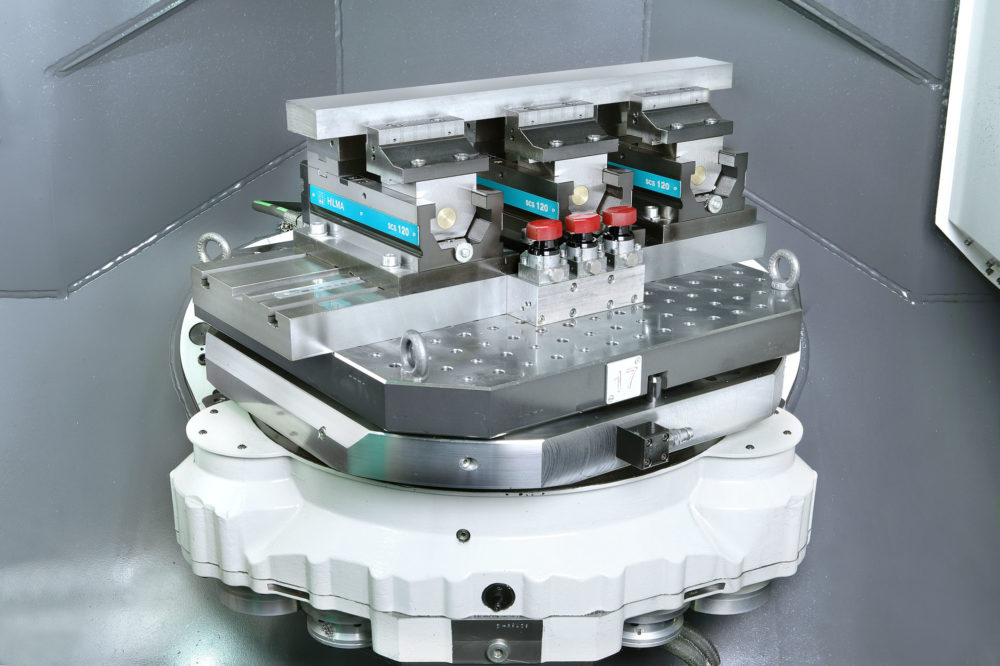

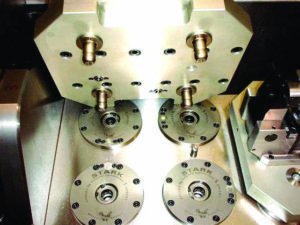

Roemheld also offers high technology, innovative Stark Zero Point Mounting Systems. These revolutionise setup times and keep downtime to a minimum. They combine high accuracy with ease of use across a wide range of applications. The compact construction of the elements enables them to be used for fixtures and cubes as well as attached directly to Vertical, Horizontal and 5-Axis machine tables.

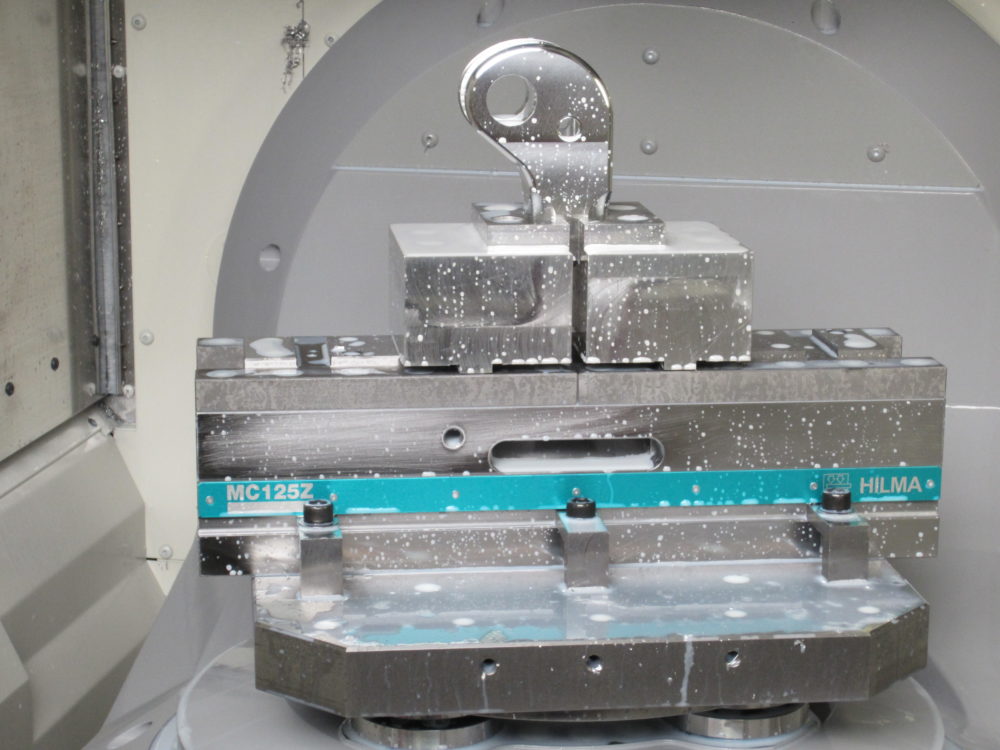

Hilma Roemheld products are designed to offer increased efficiency, reduce changeover times and provide savings in downtime. This results in cost-effective, quick, safe clamping across a wide variety of different applications, whether mechanical or hydraulic workholding solutions are required and, in particular, when 5-Axis machining.

Quick Die Change and Quick Mould Change are areas that Roemheld excels in. QDC systems are offered hydraulically,mechanically, electromechanically and magnetically. These elements can be retrofitted to existing press machines or supplied as turnkey projects on new machines.This technology offers end users the ability to improve changeover times and drastically reduce downtime when changing from one batch of components to another.

M-TECS Magnetic Clamping techniques for the plastics and rubber industries offer temperature resistant clamping up to240°C and are suitable to retrofit on machines already in production.

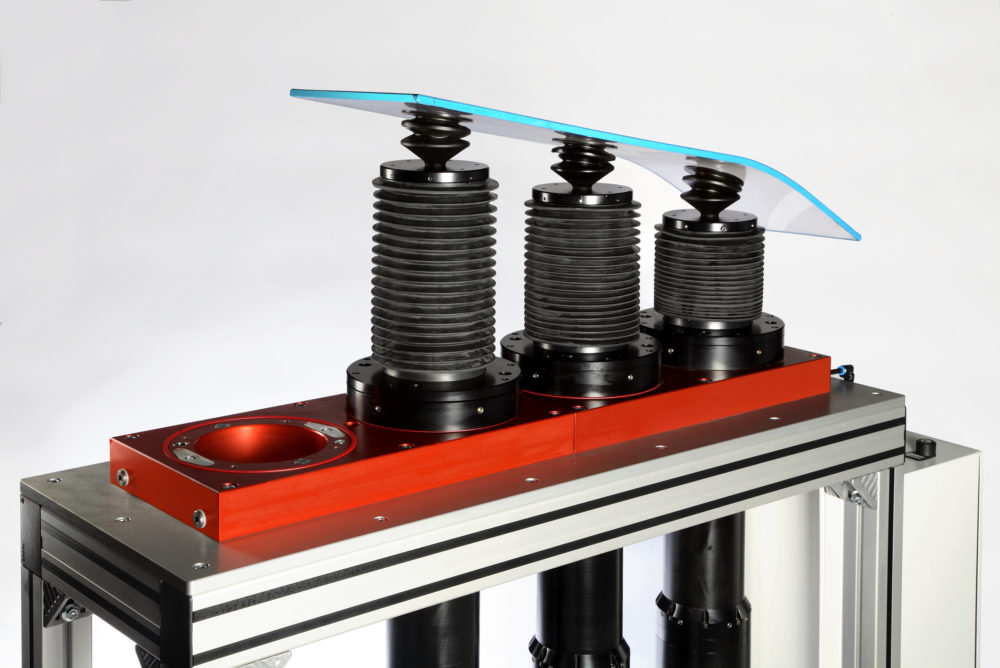

To optimise assembly processes and offer economic alternatives for automated systems,Roemheld has developed special high performance telescopic lifting units for the automotive industry and similar fields of application.These enable motor-driven height adjustments of assembly fixtures, supply systems and working tables, as well as controlled lifting and lowering of charges.With an admissible lifting capacity of 7500N and an admissible lifting speed of 300Nm, these units enable the absolute synchronisation of columns, with no locking between columns possible.

Roemheld can also offer new workholding innovations in the positioning and clamping of components, designed to provide substantial cost per part savings. Roemheld products can help drive competitiveness, by adding value to the manufacturing of engine parts; pressing of body parts and the assembly of motor vehicles.

Roemheld’s new Rotor Locks for the wind turbine industry offer hydraulic, electro-mechanical and modular design, that meet and exceed the requirements of offshore wind power stations.

The new E-Tecs range of electro-mechanical clamping systems is suitable for automatic manufacturing systems, robotics, assembly equipment, test systems, clean room areas, and the food and packaging industries.

Roemheld offers application solutions for a wide range of industries including automotive, aerospace, medical, plastics and rubber, food and packaging. So whether you are looking to purchase a new or retro fit clamping system, call us now. You will be surprised at the results we can help you obtain.

Contact Roemheld UK Limited

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU