R-Winter Tooling

R-Winter Tooling is a modern design & engineering business based in Rochester, Kent.

R Winter Tooling is a modern design & engineering business based in Rochester, Kent.

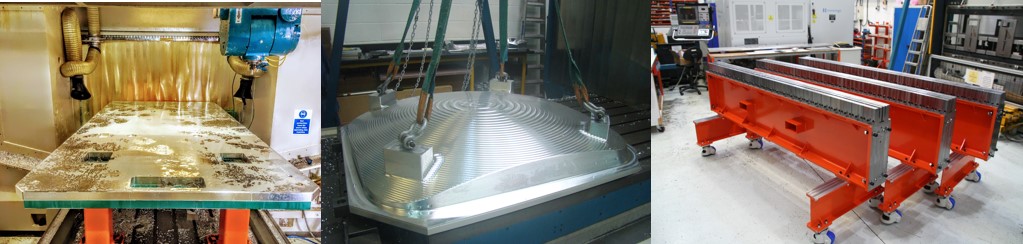

The main aspect of R-Winter Tooling is production machining, specializing in high tolerance components. With our extensive experience in design and manufacture of checking & assembly fixtures, it allows us to approach production with a sophisticated and efficient approach.

To support this we have a dedicated quality/ inspection department. R Winter Tooling have been ISO 9001-2015 accredited for many years. In 2024 we increased our scope for “manufacture of high precision components” in line with our existing and future clients wishes.

Capabilities and Skill Set

Machining a broad spectrum of materials and metals including hardened Tool Steel to 62 HRC.

Our team consists of experienced CAD (Catia V5) and CAM engineers using large capacity 5 axis machines (up to 3.5m) along with a variety of machining centres up to 2.1m (VMC).

These attributes and facilities allow us to produce components and tooling to a very high standard.

Products and Services

- 3 axis / 3+2 axis / 5 axis Machining of large parts (Up to 3.5 metres)

- Precision production machining

- General small batch machining

- CAD/CAM facilities (Catia V5 – Three CAD engineers - Access to most CAD formats)

- Design/manufacture of assembly, checking and routing fixtures

- Pattern/tool making for carbon/pre-preg and GRP

- Various types of tooling from veneer press tooling to vacuum forming tools

- Carbon/pre-preg and GRP trimming

Equipment

- Correa FP40 – 5 Axis Gantry Mill – 3.5m x 3m x 1.25m (Tool Steel Capability)

- Correa – 5 Axis Gantry Mill – 3.25m x 2.35m x 1.2m (Tool Steel Capability)

- Hermle C400 – 5 Axis Trunnion Machining Centre

- Mazak I500 – 5 Axis Trunnion Machining Centre

- Doosan – DMG – X3 Machining Centres up to 2.1m (VMC)

- CMZ Lathe – TA-20-Y-640 – C & Y Axis Milling – Max Turning Diameter – 460mm

- Mitutoyo Fixed Gantry CMM – Measuring Window – 1`600mm X 900mm X 800mm

- Mitutoyo Fixed Gantry CMM – Measuring Window – 500mm X 400mm X 400mm

- Creaform Portable CMM Optical Inspection System – 7.8 Cubic Metre Measuring Volume

Contact R-Winter Tooling

"*" indicates required fields