Pentagon Plastics Group

Pentagon Plastics Group are expanded rapidly and are now one of the UK’s leading mould manufacturers. They are able to produce moulds to customer specifications and they also have machining capabilities for small bath work and production turning.

Pentagon Plastics provides extensive services to plastic injection moulders as your centre of excellence for mould tool servicing, repair, modification, pre-production development and production mould tools. Through our generous machine selection, we also provide a subcontract machining service. Based in Horsham, West Sussex our UK engineering business offers a wealth of technical knowledge and experience.

The company has traded for over 60 years and in July 2016, Phoenix Engineering became part of Pentagon Plastics and now forms part of the Tooling Division within the group. Now benefiting from enhanced technical and office support as well as widening the range of accessible manufacturing machinery and tooling capabilities.

Maintenance and Servicing

It is vital that tools are maintained and serviced at regular intervals to ensure that production demands can be met and that the tool continues to function in an acceptable manner. Preventative maintenance can help to avoid breakdowns which can prove costly in the manufacturing cycle.

To facilitate this work, we have developed a robust maintenance and service program to support our customers’ requirements. By working closely with them we can schedule the work to be completed at mutually convenient times to meet their production needs and our own capacity.

Repairs and Modifications

A mould tool is a significant investment and it is important that when issues occur in production that the tools can be repaired to reduce the impact of breakdowns. We also find that many customers want to realise the best value out of their investment and look to up issue parts in a tool rather than invest in new tooling. When practical to do so they will replace an obsolete product with a new part utilising an existing bolster set and hot runner system.

Customers may look to adapt their existing tooling to enhance product designs or modify existing mould tools to produce up issued products. We are also experienced in the repair of existing tools when there is a breakdown or to re-instate cavities that may have been turned off in production due to cavity damage or perhaps water leaks.

Pre-production Tooling

We have assisted customers in the development of a product taking it from concept through to production tooling. The process can follow many forms and the solution we recommend is often bespoke to the project in hand.

At an early stage we can provide rapid prototype solutions in-house or via a managed service. To mould a product in various thermoplastic materials or in the specified material for production we can manufacture dedicated pre-production mould tool solutions. These can take different forms such as a basic Modular Insert System, Basic Mould Tooling or complex single cavity tooling with hot tip feed.

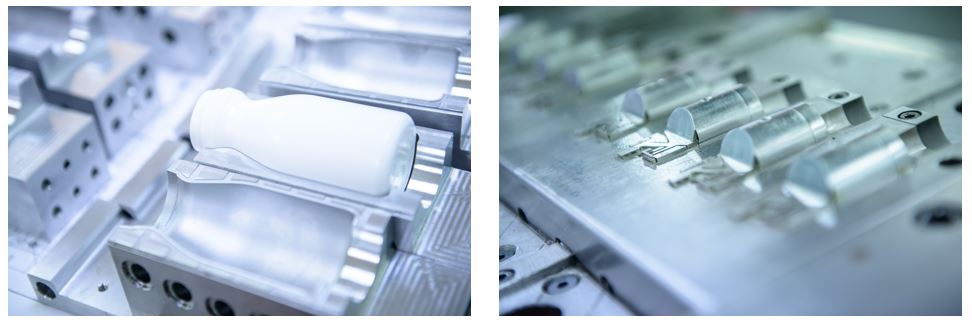

Production Tools

At Phoenix Engineering we pride ourselves on being able to manufacture this form of tooling to exacting standards, with a high level of traceability and with quality controls throughout the process.

Production tools would usually be manufactured with fully hardened tooling plate being used for core and cavity details as well as side movements and crucial shut out areas. Many production tools produced serve the Caps & Closure and Medical markets being multi-cavity Hot Runner tools with complex forms however cold runner tools including single cavity and family tools are also manufactured to support our customers’ requirements.

Predominately the production tools we manufacture are run in our customers mould shops and are supported at Phoenix, but we do now have the capability through our sister company Pentagon Plastics Ltd to store mould tools and produce repeat production on press sizes up to 280 tonnes when required.

Sub Contract Services

Some of the parts we produce include punch & dies, jigs, fixtures, gauges, nests and forming tools amongst others.

The machines that can be utilised are listed below and we provide the same high standard of engineering capability to this work as we do to the mould tools we build: –

- Jig Grinding

- Cylindrical Grinding

- Surface Grinding

- CNC Milling

- CNC Turning

- Wire Eroding

- Spark Eroding

Over the last two years we have made extensive, self-funded investment in to our plant and our workforce. The most recent investments have been into state-of-the-art laser welding technology and two new CNC machining centres (3&5 axis).

Pentagon Plastics continues to go from strength to strength in UK mould tooling and you can rest assured that your investment is in safe hands.

SPARK EROSION

1 Off – VECTOR 800×400

2 Off – LINESPEC 800×400

3 Off – CHARMILLES ROBOFORM 20 700×350

1 Off – AGIETRON COMPACT 3 1005 X 780

WIRE EROSION

1 off AGIECUT CLASSIC 2S

MILLING MACHINES

1 Off – KONDIA FVL 700×360

1 Off – TOS FNK25 800×360

1 Off – ETM 4VS 440×670

1 Off – HURON M2000 2000×460

LATHES

1 Off – COLCHESTER STUDENT 635×330

1 Off – COLCHESTER TRIUMPH 2500 878×390

1 Off – DAEWOO PUMA 10 HC CNC 530×330

1 Off – HYUNDAI HIT15S CNC 500×254

INSPECTION

1 Off – Mitutoyo BN706 CNC MMM

1 Off – BATY SHADOWMASTER SHADOWGRAPH

1 Off – FERRANTI COORDINATE MEASURING MACHINE

COMPUTER INTEL CORE 2 DUO

1 Off – 2.40 GHZ WITH DEPOCAM

MACHINING CENTRES

1 Off – BEAVER 600 TOOLMAKER CNC 600×700

1 Off – BRIDGEPORT VMC 500X DIGITAL CNC

500 x 300 (with 16 position toolchanger)

GRINDING MACHINES (SURFACE)

3 Off – JONES & SHIPMAN 540 457×152

1 Off – KENT KGS-510AHD 1000×500

GRINDING MACHINES (UNIVERSAL)

3 Off – JONES & SHIPMAN 610×254 Dia

JIG GRINDING MACHINES

1 Off – MOORE 2C

MOULDING PRESSSES

1 Off – DEMAG 175

ULTRASONIC CLEANING TANK

CC HYDROSONICS BESPOKE SYSTEM

1 Off – Tank size 1100x400x600

Tank size 300x300x300

VARIOUS:- HEIGHT GAUGES, MICROMETERS, SLIP PACKS ALL REGULARLY CALIBRATED.

DRAWING OFFICE

1 Off – PENTIUM 4 – 2.4 GHZ WITH 2D & 3D SOLID MODELLING

1 Off – PENTIUM 4 – 3.6GHZ WITH 2D, 3D SOLID MODELLING & 3D/2D SURFACE MACHINING

1 Off – AMD SEMPRON 2600 1.8 GHZ

1 Off – HEWLETT PACKARD DESIGN JET 500 INKJECT COLOUR PLOTTER

MODEM INTERFACE

MISCELLANEOUS

VARIOUS TOOLROOM EQUIPMENT, SAWS, CUTTERS, GRINDERS, DRILLS, ETC.

COMPUTER AMD ATHLON 64 1.81 GHZ

Contact Pentagon Plastics Group

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU