Tekniplaz Limited

Injection Mould Toolmakers To The Plastics Industry & Precision Engineers

Tekniplaz is your product development, toolmaking and precision engineering partner.

We are a technical centre of excellence in the design and development of precision plastic injection-moulded products, manufacturer of associated injection mould tooling and precision engineered components.

Tekniplaz turns your idea into a finished product in one seamless turnkey service. Whatever you need – product design and visualisations, prototyping, toolmaking, precision engineered parts, modifying and repairing moulds or the production process – it’s all under one roof at Tekniplaz.

Many factors have to come together to produce parts which are world class in their quality and commercially viable:

- High-calibre product development expertise and technology

- State-of-the-art precision engineering and toolmaking facilities

- Including modification, repairs and maintenance of tooling.

All of that expertise is in-house at Tekniplaz.

That’s why, Tekniplaz is trusted by so many clients to breathe production life into their existing projects and their fresh ideas.

Rather than orchestrating several and separate parties, the Tekniplaz team transforms your outline idea – or your CAD data – into a final product, managing any challenges along the way, all under one roof.

So without fragmentation between innovation and finished product, the process flows efficiently and avoids potential dispute between several parties.

Getting your precision-engineered product off the drawing board and ready for profitable production takes someone on your side with an in-depth knowledge of the industry, our services and facilities include:

- Product design and photo-realistic visualisation using state-of-the-art CAD software including Solidworks, Inventor, Keyshot and ZW3D.

- Toolmaking (mould making) – from low volume semi-automatic aluminium or pilot tooling to high volume, multi-impression, fully automatic, production tooling.

- Modifying, maintenance and repairing moulds.

- Prototyping in house using industrial polyjet 3D printing and FDM technology in multiple materials +/- 16µ to 28µ.

- Photo-realistic rendering of products.

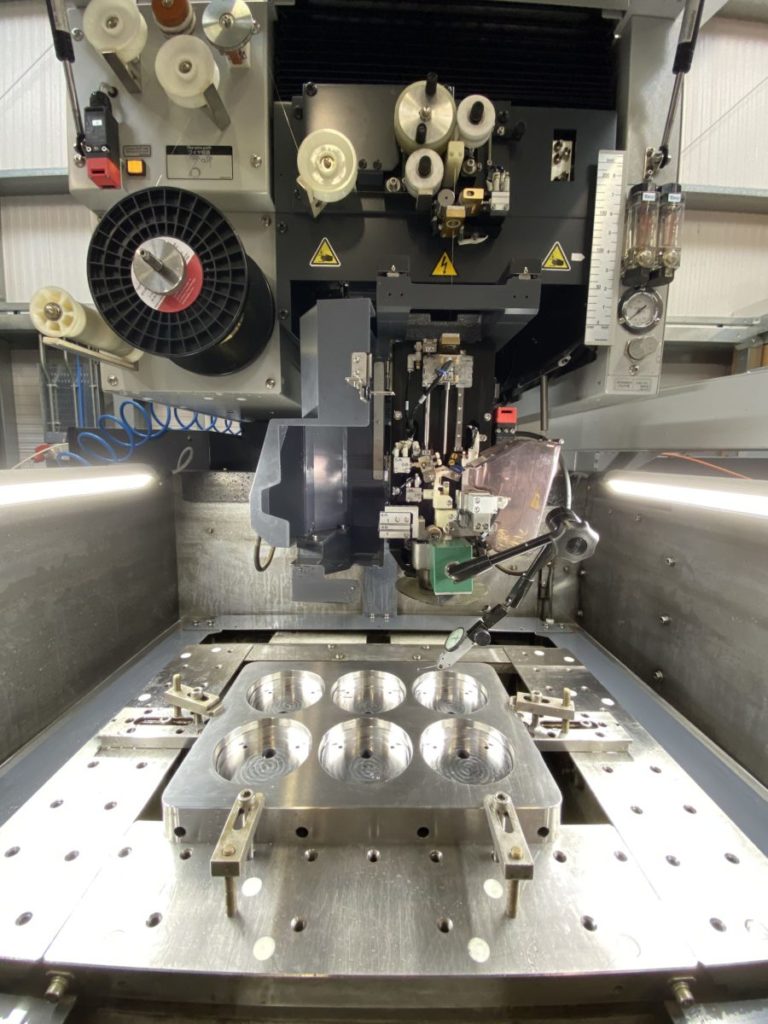

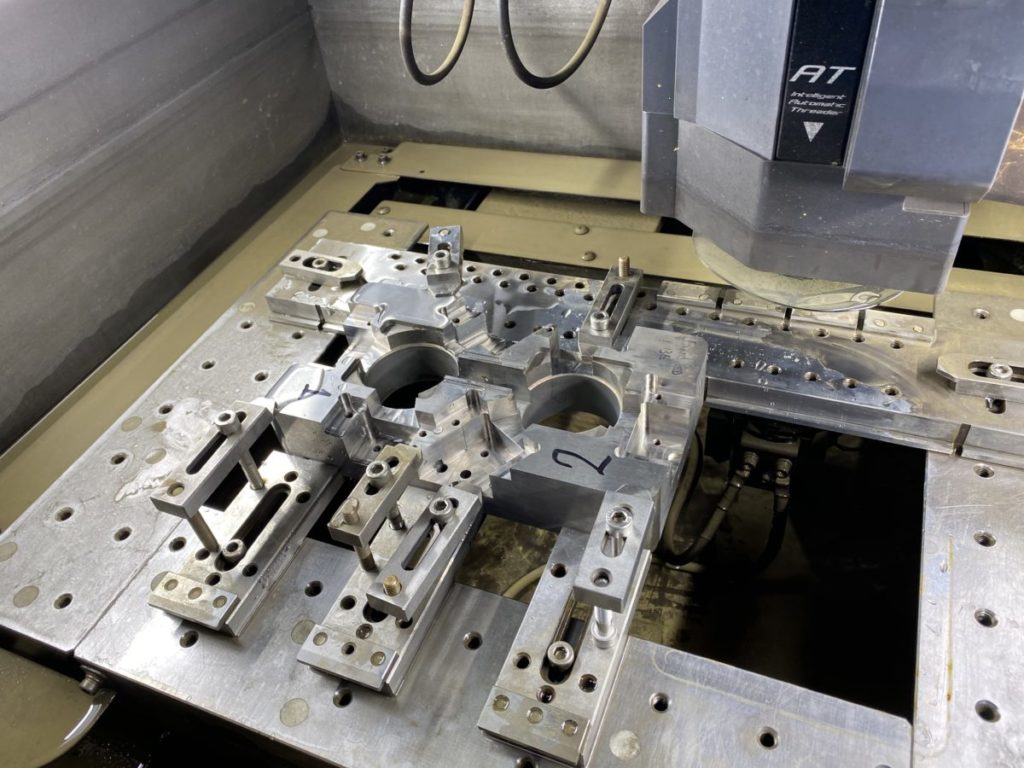

- CNC EDM (electrical discharge machining) often referred to as spark machining, spark eroding, burning, die-sinking, wire burning or wire erosion.

- High speed CNC machining.

- Manual machining

- Surface grinding

- Additive manufacturing services.

- Vacuum casting

- Digital reverse engineering.

- Highly competitive offshore manufacturing solutions

You need a partner who understands the production process intimately.

Generally, every element in the process will contribute a different approach so, when you work with us, you’ll have plenty of choice.

Think of us as your own, in-house, technical department. We may be in another building but you work with us, just as you would any other member of your team.

Call us on +44 (0)1623 880400 or email info@tekniplaz.com to help us understand your idea so we can illustrate the Tekniplaz approach – no charge.

Let’s hope that will be the first of many conversations in our enduring business partnership because we’ll not settle for anything less than your complete satisfaction, no matter how demanding or discerning you may be.

Contact Tekniplaz Limited

"*" indicates required fields