Faulkner Moulds

Faulkner Moulds has over 35 years of experience in high quality toolmaking and product and tool design. Three-times winner of UK ‘Toolmaker of the Year’, we specialise in creating technically complex tooling solutions and high production multi-cavity tooling, designed for manufacture, serving many sectors including medical, packaging, electronics, automotive and industrial.

GTMA Featured Company

Toolmaker of the Year – 2019, 2018 & 2016

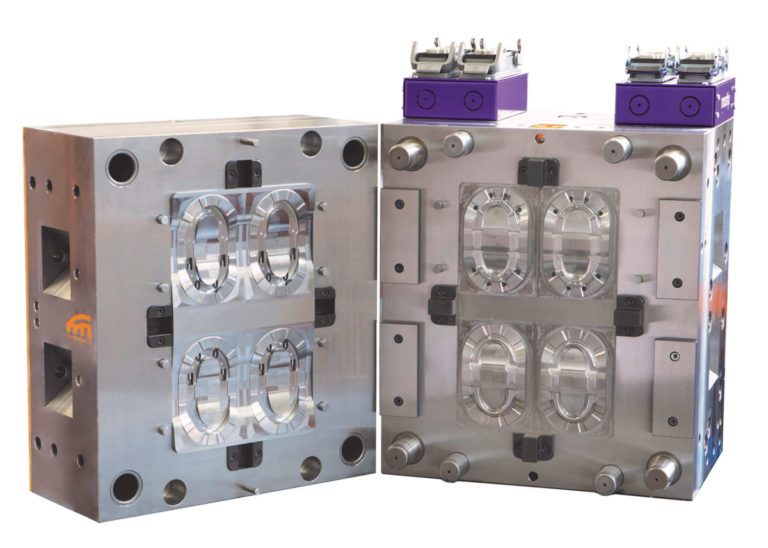

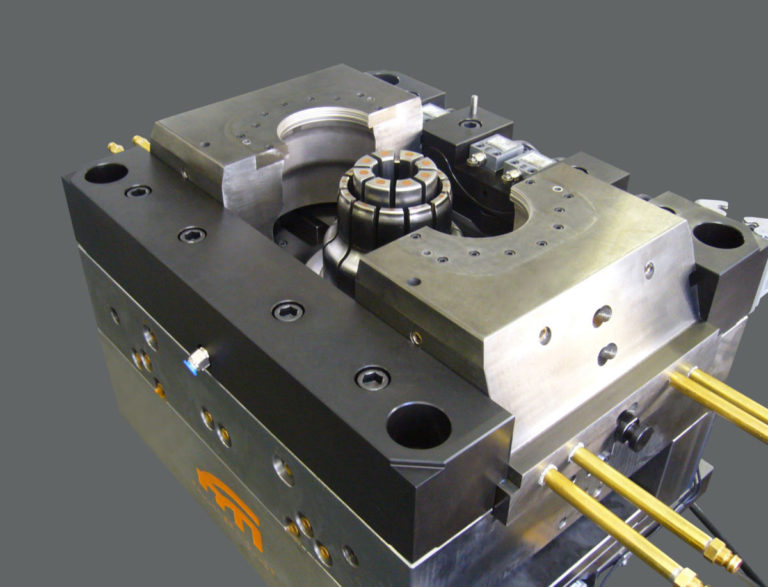

Faulkner Moulds has over 35 years’ experience of quality precision toolmaking and product and tool design. We are three times winner of the prestigious Plastics Industry Award for UK ‘Toolmaker of the Year’, winning in 2019 for what our customer called, “exceptional customer service” that is “second to none”, when we created a complex twin-shot medical tool, delivered ahead of deadline, that successfully moulded usable products at the first trial (pictured). We specialise in creating technically complex production tooling solutions, designed for manufacture.

Combining traditional toolmaking skills with state-of-the-art modern machining technology, Faulkner Moulds creates long lasting, high production and low maintenance plastic mould tools.

We offer a 1 million shot tooling guarantee on our mould tooling and serve many sectors including medical, packaging, electronics, industrial, consumer and automotive. As an ISO9001:2015 certified company, we carry out rigorous testing and measurement at every stage.

“Faulkner Moulds will look critically at the product and every aspect of the manufacturing process and come up with their own, innovative, recommendations. With Faulkner Moulds, we are reassured that we don’t just get what we believe we want, we get exactly what we need.” – Director, leading hand tool and shovel manufacturer.

Capacity and Technology

Faulkner Moulds invests in the best machinery and equipment to continually improve the service we provide. Technology is used alongside apprentice-trained, superb manual skills, creating excellence in mould toolmaking.

Consequently, we have now almost eliminated the fitting time needed at the end of each tooling project and have a strong track record of delivering tooling on time, that moulds right first time.

We have facilities for full 3D CAD and CAM design including multiple SolidWorks and SolidCAM current licences. Our machining capabilities include CNC spark and wire erosion, surface grinding, cylindrical grinding, turning and honing. Our state-of-the-art high speed vertical 5-axis graphite and hard metal machining centre enables automation of electrode manufacturing and die face finish machining, achieving a repeatable accuracy of 2 microns.

Our newest machines include a top range wire erosion machine, which allows us to create innovative wire eroded toolmaking solutions, on parts up to 1250 x 975 x 500, achieving mirror finishes with maximum accuracy. Our new CNC spark erosion machine is guaranteed to machine to a constant accuracy of 3 microns. Our suite of high specification CNC machinery will machine to a maximum of 1000 x 600 x 500.

Our versatile new Hurco TM8i 2 axis CNC turning centre (lathe) has in-built features to ease programming, enhance machine speed and ensure outstanding accuracy and surface finish. It is ideally suited to the fast-paced demands of modern toolmaking. Faulkner Moulds’ recent experience in high precision turning includes projects for the medical, packaging and industrial sectors.

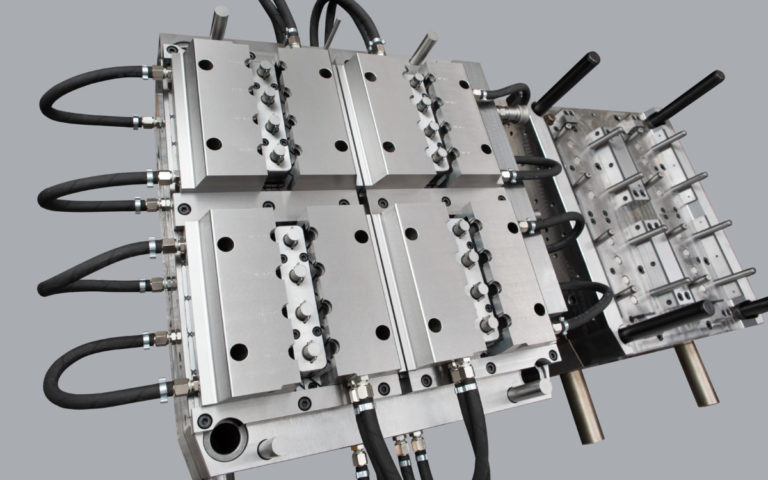

Multi-Cavity High Production Tooling

Faulkner Moulds has sound experience in high production multi-cavity mould tooling for many sectors including medical and packaging, guaranteed for a million shots.

The first tool pictured below has 16 impressions and moulds at an efficient 7 second cycle time. The second tool pictured below is a 12 impression packaging caps and closures tool for a household name. We successfully reduced the cycle time from a target of 8.5 seconds to just 6.98 seconds.

In 2022, we installed an innovative production robotic cell that we believe is a ‘world-first’. It has created efficiencies that we have been pleased to pass on to our customers, especially for multi-cavity production tooling.

Experts in Product Design and Development

Faulkner Moulds have helped to develop many products, including patented ideas, award-winners and world firsts, helping these to achieve their maximum potential and sell successfully. We have our own in-house design team for component and tool design, using current SolidWorks and SolidCAM multiple licences.

We guarantee complete confidentiality for our customers’ inventions and products. Our design and tool making is all carried out in-house, providing an extra level of security that quality is consistent, whilst ideas remain confidential.

Leaders in Design for Manufacture

Our product and tooling designs are created with both aesthetics and successful manufacturing in mind. We ensure every tool we make provides reliable, smooth-running production, giving a long, profitable life for the customer. Our design for the world-first and award-winning Universal Water and Rodent Non-Return Valve was a finalist for Industrial Product Design of the Year at the Plastics Industry Awards.

“Faulkner Moulds are more than just a traditional toolmaker. They have real passion for Design for Manufacture principles and a genuine interest in our products, their function and the marketplace they serve. This enables them to offer very cost-effective tooling design solutions and product features.” – Electrical component manufacturer

Experience

We have served clients from a wide range of industries, on a diverse range of projects, including blue chip customers and ‘household names’. Examples include medical, packaging, electronics, automotive, consumer, household and retail products. For more information, including our gallery and customer testimonials, please visit www.faulknermoulds.net/experience, call 01422 371072 or download our brochure here.

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU