Dudley Associates Ltd

Dudley Associates: Precision Tools and Plastic Injection Moulding.

Founded in 1991, Dudley Associates has a very extensive and successful history specialising in Product Design and Development, Rapid Prototyping, Tool-Making, Plastic Injection- Moulding, Assembly and Packaging, all of which are conducted in-house using our on-site facilities.

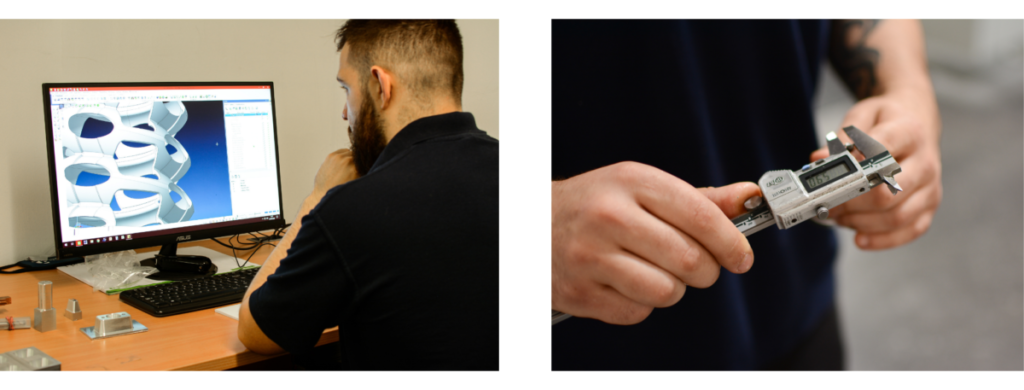

Design and Development

We can offer full product design services using the latest CAD software to produce your plastic injection moulded components, with all part designs optimised for injection moulding. We can advise on material choice and work closely with many material suppliers to ensure that you get the right material for your job. When the design is complete, we can supply prototypes for design validation.

Rapid Prototyping

We can assist you with rapid prototyping of your products in any of a wide variety of processes, depending on the number of samples required, such as; SLA 3DPrinting, SLS, Carbon Filled SLS, FDM, Polyjet Printing, Metal 3D Printing, Colourjet Printing, Rapid Aluminium Tooling and 3D Machining. We offer this service to customers who have an idea of a product that needs trialling and testing before going out to market, or projects which are the very early stages of design and testing.

It is also used when companies have a strict and tight timeline and need a product manufacturing quicker than the normal tooling and injection moulding process timeframe.

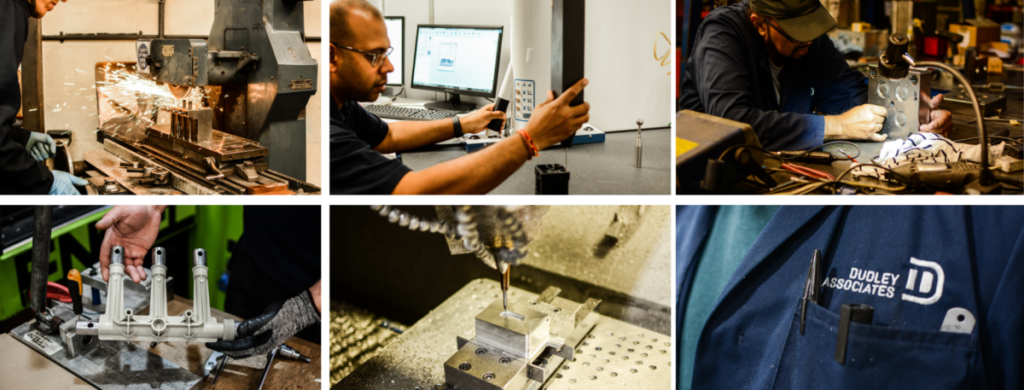

Our Facilities

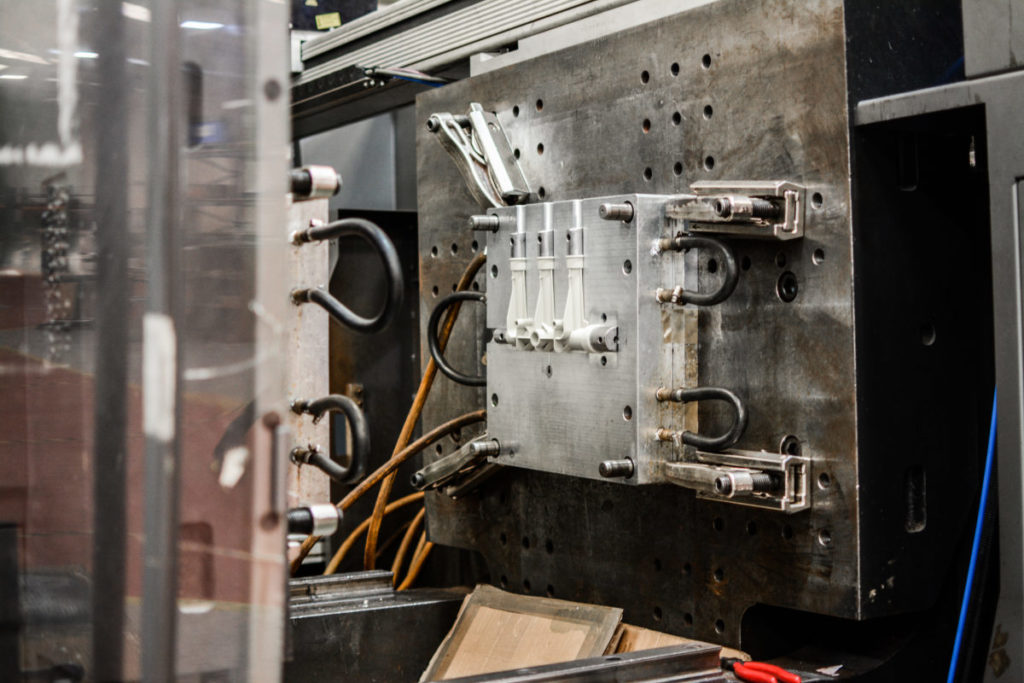

Continuous expansion and investment has seen the purchase of our state of the art high-precision, high-speed 3-axis CNC production cell with full automation, the Roeders RXp500.

Over the past decade, the company has trebled its footprint which allows adequate space for current operations and room to expand capacity further.

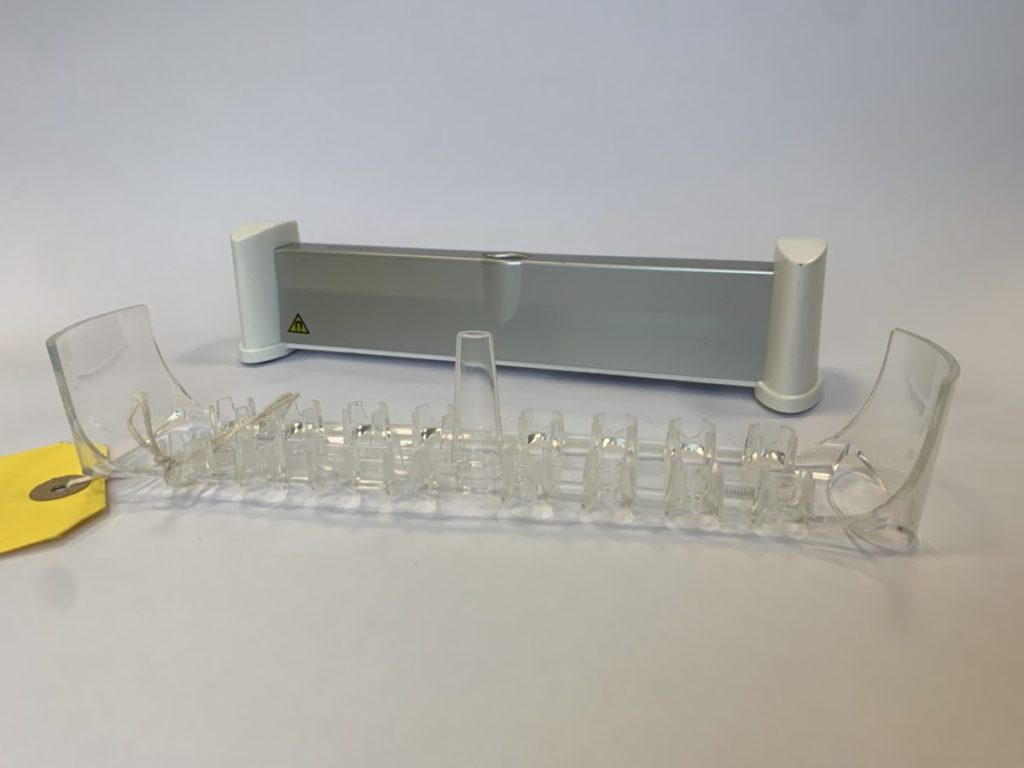

We also have invested in a Class 8 Cleanroom facility, ensuring that we have full and extensive capabilities to cater to all of our customers over a vast range of industries.

Secondary Services

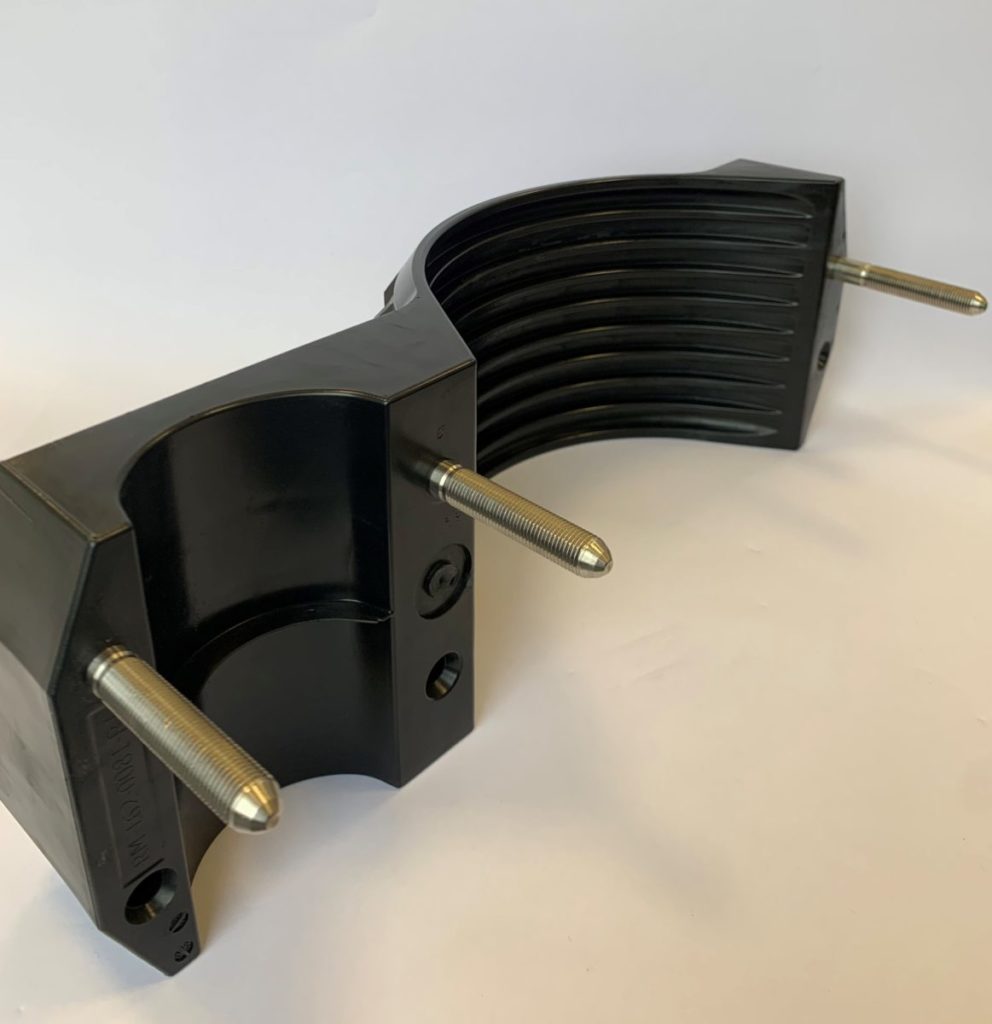

Not only do we offer leading plastic injection moulding and toolmaking, we also provide our customers with a whole host of secondary services. These include Assembly, Overmoulding, Ultrasonic Welding, Inserting, Tapping, Drilling, CNC Machining, Printing and Packaging.

Why Choose Us?

We are ISO 9001:2015 Quality Management certified and are here and ready to help, whether you are looking to:

- Launch a new project with tooling, followed by injection-mould manufacture of components;

- Run a quick turnaround prototype exercise;

- Use a local manufacture to reduce timelines, shipping costs and improve your carbon footprint;

- Re-shore existing manufacturing – including moving existing tooling from overseas;

- Find a partner who can cope with any plastic polymer and bespoke colour matching

We have tremendous client retention and repeat business levels; because we are reliable and approachable.

Throughout the duration of your project, upon completion and beyond, we provide full account management, giving you full transparency of order progress and more, from design to production.

So that’s why Dudley’s is your first choice plastic injection moulding and tooling provider

Contact Dudley Associates Ltd

"*" indicates required fields

Manufacturing Resource Centre, Adams Way, Alcester, Warwickshire, B49 6PU